Measurement: 3, micrometers

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

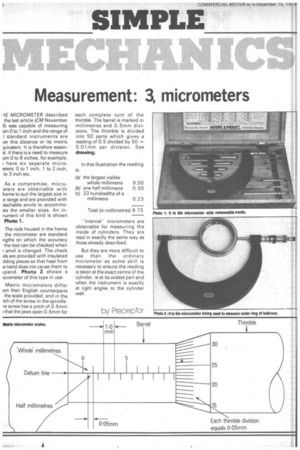

-IE MICROMETER described the last article (CM November 4) was capable of measuring om 0 to 1 inch and the range of I standard instruments are ier this distance or its metric Iuivalent. It is therefore essenal, if there is a need to measure om 0 to 6 inches, for example, ) have six separate micro'eters: 0 to 1 inch, 1 to 2 inch, to 3 inch etc.

As a compromise, microeters are obtainable with frame to suit the largest size in e range and are provided with .tachable anvils to accommo)te the smaller sizes. An inrument of this kind is shown Photo 1.

The rods housed in the frame the micrometer are standard ngths on which the accuracy the tool can be checked when anvil is changed. The check ids are provided with insulated plding pieces so that heat from le hand does not cause them to icpand. Photo 2 shows a icrometer of this type in use.

Metric micrometers differ om their English counterparts the scale provided, and in the tch of the screw in the spindle. screw has a pitch of 0.5mm )that the jaws open 0.5mm for each complete turn of the thimble. The barrel is marked in millimetres and 0.5mm divisions. The thimble is divided into 50 parts which gives a reading of 0.5 divided by 50 0.01mm per division. See drawing.

In this illustration the reading is: (a) the largest visible whole millimetre (b) one half millimetre (c) 23 hundredths of a millimetre 9.00 0.50 0.23 Total (in millimetres) 9.73 "Internal" micrometers are obtainable for measuring the inside of cylinders. They are read in exactly the same way as those already described.

But they are more difficult to use than the ordinary micrometer as some skill is necessary to ensure the reading is taken at the exact centre of the cylinder, ie at its widest part and when the instrument is exactly at right angles to the cylinder wall.