't/OtWScreect Pounds Earn

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

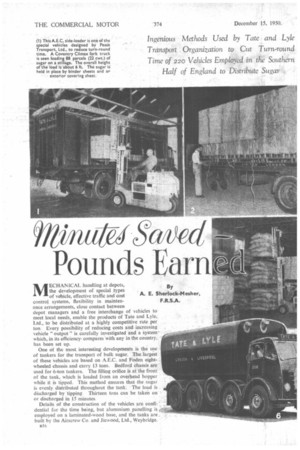

By A. E. Sherlock-M esher, F.R.S.A. MECHANICAL handling at depots, the development of special .types of vehicle, effective traffic and cost control systems, flexibility in maintenance arrangements, close contact between depot managers and a free interchange of vehicles to meet local needs, enable the products of Tate and Lyle, Ltd., to be distributed at a highly competitive rate per ton. Every possibility of reducing costs and increasing vehicle " output " is carefully investigated and a system which, in its efficiency compares with any in the country, has been set up.

One of the most interesting developments is the use of tankers for the transport of bulk sugar. The largest of these vehicles are based on A.E.C. and Foden eight wheeled chassis and carry 13 tons. Bedford chassis are used for 6-ton tankers. The filling orifice is at the front of the tank, which is loaded from an overhead hopper while it is tipped. This method ensures that the sugar is evenly distributed throughout the tank. The load is discharged by tipping Thirteen tons can be taken on or discharged in 15 minutes.

Details of the construction of the vehicles are confidential for the time being, but aluminium panelling is employed on a laminated-wood base, and the tanks are built by the Airscrew Co. and Jicwood, Ltd., Weybridge. Another example of enterprise in cutting down turnround time is to be found in a vehicle designed for sick loading and unloading by means of fork trucks. A light-alloy partition extends longitudinally down the centre of the body between the front and rear bulkheads, and palleted loads are placed on each side of it These are retained in position by several binder sheets which, • at their upper ends, are attached to the partition. When these sheets have been secured by straps to hooks on the floor side rails, a further covering sheet is lowered by means of ropes from the light-metal roof framework and is tied down. Thus, the pallets cannot move in transit and the sugar is completely protected against the weather By the use of a fork truck, the vehicle can be loaded or unloaded with 13 tons in 15 minutes.

Broadly, Tate and Lyle's transport problem is con

cerned with the distribution of sugar and syrup to wholesalers and retailers from two refineries in London and one in Liverpool through the agency of transit depots. The northern organization is based on Liverpool, where road transport is employed for the haulage of 2,000 tons of raw material a day from the docks to the refinery, as well as for the distribution of finished products In the case of the London refineries—one at Silvertown and the other at Plaistow; which, combined, form the centre of the network in

southern England —raw cane sugar is received directly by sea, and raw, homegrown sugar by road, rail and water: In the London area atone, an average of 10,000 Ions a week of refined sugar is delivered to customers by the refiner's own vehicles.

Transport for Tate and Lyle, as well as a great deal of warehousing in the south •of England, is undertaken by a wholly owned

t subsidiary„, Pease Transport, Ltd:, which, except in the case -of one depot, operates under C licences.' Vehicle maintenance is performed by another subsidiary, Fisher and Stacey, Ltd.

The Silvertown refinery, one of the biggest in the world, houses the largest depot of Pease Transport, Ltd. Others are located at Wandsworth (London), Taunton, Elmswell (Suffolk), Whitton (near Daventry), Stoke Orchard (near Cheltenham), Bristol, Caversham and Cardiff. Thc Cardiff depot is supplied from Liverpool, where the Tate and Lyle organization owns one warehouse and rents others Further depots are being completed at Southampton and Tavistock. Waterside warehouses of Coast Lines, Ltd., at Falmouth, Plymouth, Poole and Southampton are also used and distribution by road is carried out from them.

From London, services arc run daily and as required to Bristol, Daventry and Caversham. The other transit depots also receive supplies once a day.

An experimental packing station is being built on model lines at Bristol, beside the existing warehouse. It is to feed this station that the tankers, carrying altogether 200 tons of refined, unpacked sugar each day and completing the round trip in 24 hours, are being employed.

Some b.:1k sugar for distant destinations is sent by rail, but all packet sugar, which is fragile, goes by road. Packets, which may contain 1 lb., 2 lb., or 4 lb., are assembled in 28-1b. parcels. Other grades of sugar are contained in 1-cwt. hessian or paper bags and in 2-cwt. hessian sacks. Syrup is sold in I lb., 2 lb., 14 lb., and 28 lb. tins, which are packed in 56 lb. fibre containers. , Manufacturing syrup is supplied in drums.

Little Empty Mileage

Empty running by all trunk vehicles is kept to a minimum. On return journeys from Cheltenham, for instance, tinplate is often carried. It is packed in 1-ton fibreboard bales, to which single-faced pallets are strapped, and it is easily handled by fork trucks. Paper and bags form other return loads, in addition to which sugar has to be brought in from Ministry of Food buffer depots in remote country districts, where some o.f it is stored during the winter.

Rationing and the bonus issues which are made periodically cause the demand for sugar to risc and fall in eight-week cycles. A peak occurs at the beginning of every eighth week and then the demand subsides until the fourth week, when the delivery graph again jumps up and afterwards falls progressively until the end of the period is reached. Although Pease Transport, Ltd., has 220 vehicles of its own in the area based on London, the fleet is not large enough to deal with peak traffic and extensive use is made of hauliers' services.

Great care has to be exercised in hiring vehicles, because sugar easily picks up smell on the surface and it cannot be carried in lorries which have been contaminated by earlier loads. For this reason also it cannot normally be mixed with other goods. Hauliers' vehicles are used mainly to feed the depots with bulk supplies, rather than for retail delivery.

Apart from the tankers, the fleet consists of platform lorries and boxvans, many of the latter carrying striking

• pictorial displays on their, side panels. About half the

vehicles are 6-tonners and 50 have oil engines The biggest machines are 15-ton eight-wheelers. ,

The 220 vehicles comprise 115 Bedford (including 16 Bedford-Scammell articulated 8-tonners), 29 Foden, 21 Dennis, 20 Morris-Commercial, 15 A.E.C., 10 Dodge, five Scammell, three Diamond T and two International. As I explained at the outset, vehicles are interchanged between depots, but on a recent date 62 were in use at Wandsworth, 93 at Silvertown, 14 at Taunton, four at Cardiff, three at Poole, four at Caversham, four at Daventry, six at Elmswell, five at Southampton, three at Plymouth, seven at Bristol and nine at Cheltenham. The total payload capacity of the fleet is about 1,500 tons.

Delivery Rounds Looped

Each transit depot is the headquarters of a distribution zone, which Is divided into districts. Deliveries are made regularly to customers and the principle of looping rounds, so that consignments are dropped on the return journey as well as on the outward run, is observed as far as possible.

By loading vehicles overnight, journeys may be started from 6 a.m. onwards next day, and many of the vans can make two trips or more during the day. Fork trucks and other mechanical aids at the London refineries enable an average of 800-90(1 tons to be handled each night. Deliveries from Wandsworth are greatly facilitated by sending 31 vehicles every evening to the Plaistow refinery, where they collect about 330 tons of sugar and syrup and are driven back to the depot while the London streets are stilt free from traffic.

The Wandsworth depot, which can store about 2,000 tons, is the senior. It covers a wide distribution area and is immediately responsible for the Poole, Southampton and Caversham depots. ft also takes under its wing the Taunton, Bristol, Plymouth and Cheltenham branches. During slack periods, it stocks up Ministry of Food stores. The storage accommodation, like that at other depots which I inspected, is spotlessly clean, and the symmetrical stacking of goods is a model for all warehousemen. This orderliness greatly assists the physical check of stock, which, as in every other Pease, warehouse, is taken every 24 hours

The Silvertown depot is second in seniority and has certain special responsibilities. Apart from distributing to customers over a wide area to the east, south-east, south and north-west of London, it controls and supplies the depots at Daventry and Elmswell, and feeds the Bristol establishment with bulk sugar, It also handles all "inwards" packing materials and disposes of empty sacks to Liverpool and Greenock.

New bags are collected from Greenock and are taken to Liverpool, where they are exchanged for Fairrie cubes for delivery to London. Dock work is also done, as the depot has to feed coastwise and ocean ships with supplies. In this way the Silvertown depot handles an average of more than 4,000 tons a week inwards and outwards, mainly for direct delivery to customers.

The Daventry satellite itself serves an! area of 60-70 miles' radius, but is concerned mostly with syrup and speciality sugar (sugar other than granulated). In that area, granulated sugar is distributed by the British Sugar Corporation. Elmswell is notable in that it runs the only B-licensed vehicles in the fleet. B licences are necessary because delivery is undertaken also for the British Sugar Corporation, and permits have been granted by the Road Haulage Executive to enable the vehicles to travel more than 25 miles.

The Cheltenham depot, which F also visited, is a fine air-conditioned ex-aircraft hangar measuring about 90 yds. by 30 yds. It can store about 4,000 tons and does a large business in supplying sugar to factories, often delivering about 200 tons a week to them. Vehicles are loaded each evening and distribute within a 50mile radius, including Herefordshire, Gloucestershire and parts of Oxfordshire and Wiltshire.

A most ingenious movement-control system has been devised by the company, and I was able to see it in action at the Silvertown depot. It has since been installed also at Plaistow. Its value lies in ensuring that there is no delay in sending out vehicles with second loads after the first run has been completed.

A control clerk sits at a board on which red lights indicate the presence of vans waiting to load, blue lights identify bays that are empty and green lights show the vehicles which are being loaded. Immediately he arrives back, each driver reports to the clerk, who gives him an order form, stamped by a time clock, to be taken to the warehouse office. There the load is released on the authority of the order. The clerk is notified by a broadcast system from the loading bank of the time at which the vehicle arrived there, and the times when loading began and finished.

On a large plastic-covered board the clerk enters in wax pencil the lorry number, the tonnage for the vehicle, the type of goods to be carried, the number of the appropriate loading bay, the time of reporting to control, the time at which the order was lodged on the bank, the time of arrival of the lorry at the bank, the times of starting and finishing loading, the total time occupied, and the destination. This information is also recorded permanently in a daybook.

Mechanical handling at the various depots has done much to increase transport efficiency and enables the maximum use to be made of every vehicle. For transport from refineries to depots, loads of fl tons each are made up on pallets, which are normally of steel. I was interested to observe that steel pallets are used successfully for storing sugar in sacks, and at Cheltenham I saw three tiers of pallets, each carrying 15 2-cwt. bags, which had been standing for three months without sagging. Each stack weighed 41 tons. Some wooden pallets are also being used, but, with

characteristic ingenuity, Tate and Lyle, Ltd., has devised expendable single-faced pallets of its own.

These are made of waste cardboard, to which damaged syrup tins are stapled to form distance pieces. These pallets carry a ton, and 1 was surprised at the great height to which sugar is stored on them at the depots. As they cost little to make, it would not matter if they collapsed after being used once, but on-the evidence of my inspection they seemed to be remarkably durable.

Apart from pallets, 10,000 stillages are employed in mechanical handling operations in London.

At the Silvertown depot, bagged sugar is delivered to the loading bank by chute and cartons descend from the stores by lift. Stillages are employed in conjunction with manual trucks or pedestrian-controlled electric trucks, on which the loads are taken straight into the waiting .vehicles. A Coventry Climax fork truck also works on the bay and another stacks in the store.

Fork Trucks Simplify Handling At Cheltenham there are three Coventry Climax fork trucks, including a new model having a 14-ft. lift. Fork trucks arc invaluable there, because there is no loading deck other than an old trailer, and if mechanical handling was not employed, a great deal of manual effort would be required in transferring loads from the store to the vehicle. Moreover, by the use of the Coventry Climax machines, full advantage can be taken of the great amount of headroom available to stack goods to the maximum practicable height.

As I pointed out at the beginning, the vehicle maintenance system is unusual in its flexibility and some extremely informative records are kept in connection with it. The costing scheme is also most thorough. Both these aspects of fleet control play an important part in keeping down costs and promoting efficiency. and I will deal with them in greater detail next week.