A Promising Rotary Valve

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the Cross System with Which Some Excellent Results Have Been Obtained. Gas-tightness Secured by Ingeniously Simple Means

WITH the tendency for increased engine speeds, scope is offered for the development of a valve which works smoothly instead of with the reciprocating action of the familiar poppet waive. The absence of noise and shock, and the positive control of the ports at all practical engine speeds are points in favour of a rotary valve, whilst the fact that ports can be made large enough to eliminate difficulties of quick admission or release of gases, even up to abnormally high crankshaft speeds, makes the rotary valve interesting. Another point, of course, is that a more efficient shape of combustion chamber is obtainable.

The design of the valve invented by Mr. R. C. Cross, of Bath, will appeal to readers. This valve is claimed to function perfectly at speeds up to 10,000 r.p.m.—i.e., until bigend bearings fail.

A most important feature of the invention, which has been covered by patents in Britain, Germany, France, America and other countries, consists of utilizing the spring of the high-tensile phosphor-bronze sleeve to secure gas-tightness between the sleeve and the valve. The edges of the sleeve surrounding the rectangular port project beyond the supporting surfaces of the casting and are tapered. The construction-causes them to spring slightly towards the rotating valve and to make it firm contact therewith. This action is assisted by compression and explosion pressures.

By this simple expedient gas-tightness, probably the most difficult thing to obtain with this kind of valve, is claimed to have been achieved, and lubrication troubles to have been overcome, for they have, hitherto, resulted largely from gas leakage blowing oil from the valve. The valve operates at half crankshaft speed, being driven through a claw coupling, which gives sufficient freedom to allow of correct alignment in the bronze sleeve.

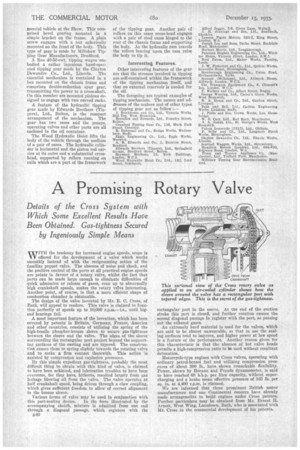

Various forms of valve may be used in conjunction with this port-scaling device. In the form illustrated by the accompanying sketch, mixture is admitted from one end through a diagonal passage, which registers with the B40

rectangular port in the sleeve. At tile cud of the suction stroke this port is closed, and further rotation causes the second diagonal passage to register with the port, so passing out the exhaust gases. An extremely hard material is used for the valves, which are said to be almost 1u/wearable, so that in use the sealing surfaces tend to improve, and higher power at low speed is a feature of the performance. Another reason given for this characteristic is that the absence of hot valve heads permits a high-compression ratio to he used witheut resultant detonation.

Motorcycle-type engines with Cross valves, operating with ordinary petrol-benzoi fuel and utilizing compression pras• auras of about 300 lb., have shown remarkable flexibility. Power, shown by Heenan and Fronde dynamometer, is said to have reached 08 b.h.p. per litre capacity, without supercharging and a brake mean effective pressure of 103 lb. per sq. in. at 4,400 r.p.m. is claimed. We are informed that three prominent British motor manufacturers and one Continental concern have already made arrangements to build engines under Cross patents. Further particulars may be obtained from Mr. Ernest H. Arnett, West Wing, Lansciov.m, Bath, who is associated with Mr. Cross in the commercial development of his patents.