A Review of Tipping Gears "

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

of Diverse Types

Some Particulars of a Wide Variety of Tipping Gears Devices that Secure Speedier Working and Reduced Costs

M()ST vehicle manufacturers appear to prefer to fit a proprietary tipping gear. Those _which sell through agents, rather than direct, usually leave this matter to the agents to decide. Experienced users often have a preference for a particular make of tipping gear, and specify that make in placing the order.

On broad grounds of economy, the power-operated tipping gear is to be recommended. It is usually much quicker in action than the band-operated gear, and as the principal object of fitting a tipping gear is to save time, the power-driven type is to be preferred, as achieving that end more effectively.

One exception to the foregoing occurs in the ease of the application of tipping gears to trailers, when, if the trailer be detached from its motive unit, no source of power'is available. There the user is offered equipment capable of

, being either power or hand-operated, according to circumstances.

Quick Hand-operated Gears.

It is fair to state that some of the manually operated gears are remarkably quick in action. Recent invention has had that need for speed as a primary concern, with necessity of weight reduction a close second.

The patent hydraulic tipping gears by Bromilow and Edwards, Ltd., Foundry Street, Bolton, are available in a• variety of 'types. Perhaps the most interesting is the new hand-operated' hydraulic' end-tipper for loads up' to four tons. This is an entirely self-contained mechanism, the whole of which,

u38

with the exception of the body-hinging brackets, is mounted upon a light cradle, which is bolted to the vehicle chassis just behind the driver's cab.

The pump, a neat twin-barrelled unit having eight valves, is located within the oil reservoir, thus economizing space and eliminating the need for a good deal of connecting piping. The ram is telescopic, and the weight of the complete

unit is only cwt.

Another interesting D. and E. gear is the ball

bearing screw tipper. In this model the nut comprises an endless chain of balls, which intervene between the specially designed threads of the nut and screw, thus reducing frictional resistance to a minimum, In also the power-operated hydraulic tipping gears of this make the pump is located in the oil reservoir. There is an adjustable pressure and overload valve on the pump, which allows the oil to by-pass when a predetermined pressure point is reached. Stops on the inner ram prevent oyertipping.

In the three-way tipping gear the rams have a universal joint, and the direction of tip is determined in the customary manner by locking and freeing appropriate hinge pins. A cut-out valve is connected to the underside of the body by a lever and cable. This valve allows the oil to by-pass when the required angle of tip is attained, but at the same time the pressure on the rams is maintained, keeping the body in the tipped position until the lowering handle is manipulated.

An Easily Fitted Device.

The Spenborough Engineering Co., Union Street, Heekroondwike, is best known by its ingenious hand-operated Upping gear, which has the outstanding advantage of needing only six U bolts to attach it to the chassis, no drilling being necessary. The gear incorporates two vertical screwed shafts with lefthand and right-hand threads, bridged at their upper ends by a pair of steel plates which carry two rollers.

Attached to the underside of the body is an inverted channel, which is curved downwards at each end and serves as a track for the rollers, The nuts on the

screwed threads are incorporated in bevel crown wheels driven by corresponding bevel pinions on a cross-shaft. This itself is driven by spur reducing gears operated by the usual squared shaft.

The foregoing is a three-way tipping gear. The Spenborough hand-operated end-tipping gear comprises a channeliron base, which carries the operating shaft and bevel gearing by which power is transmitted to the vertical screw. A special feature is the universal base, by which the screw is allowed a limited action without effecting the gear-wheel settings.

The Spenborough hand -operated three-way hydraulic mechanism is a recent introduction. Economy of weight and space is achieved by locating the hydraulic pump immediately in front of the ramp, so that only an 8-in, length of piping is required to connect.

Ingenious Action.

The action of this gear is rather in. genious. The movement of the ram is communicated through a stirrup, on which is pivoted a lifting arm. The top of this arm has rollers, which engage with steel body runners. The bottom end of the arm is pivoted on the member housing the Tam. To obtain the desired direction of tip the lifting arm is swung around to the required position.

Like the mechanically driven gear, this model can be secured to the chassis by a minimum number of U bolts. A power-driven hydraulic gear embodying an ingenious awash-plate piunp, remarkable for its small size, is the most recent Spenborough introduction. The inechanism of the tipping gear proper is similar to that just described.

A tipping gear of unusual design is the Theed. It is power driven, but utilizes compressed air, a special air compressor being fitted on the near side of the gearbox. Air is pumped to a three-way valve, through which air can be taken direct to the ram, to hold it and to lower it. With the operating handle in the mid position, air from the compressor can also be utilized for tyre iutlation and other purposes.

A Pneumatic Gear.

The ram is a single oil-sealed piston, and air enters through the hollow piston rod, the normal working pressure being about 200 lb. per sq. in. At the top the ram cylinder is attached to the front end of the body by arms and trunnions, whilst at the bottom there is an ingenious spring-controlled ball joint. This gear was invented by Mr. W. D. L. Theed, of Hamilton Motors, Ltd.. 466490, Edgware Road, London, W.2.

The Eagle Engineering Co., Ltd., Warwick, makes tipping gears in a variety of types. There are the universal single vertical screw and telescopic screw end-tipping gears designed for manual operation. There are also the patent roller-type side-tipping gear, the central twin-screw baud-operated three-way mechanism, and hydraulic gears for end and three-way tipping.

Of these, perhaps the most interesting is the hydraulic gear. The end-tipper of this type embodies a single telescopic ram universally mounted on a ball socket on its channel base, and lifting the body by means of two forged-steel links, Which are attached at the top of the inner ram and to suitable trunnion brackets on the body.

The power is supplied by a rotary gear pump, and a special power-takeoff box is incorporated in the outfit. The take-off is Idesigned to suit the vehicle gearbox, and consists of an oilretainiag case and a sliding gear to mesh with the take-off gear.

Another lightweight tipping gear by the same maker comprises a single telescopic ram at the front of the body. The ram is in three sections and is mounted on a cast-steel trunnion equipped with a special gland, through which the ram is fed.

A Double-extension Ram.

The three-way tipper embodies a single double-extension ram mounted in the middle of the chassis and engaging the body through a ball socket bolted to a suitable cross-channel secured to the body by longitudinals. In all cases these hydraulic gears embody a safety valve to prevent damage.

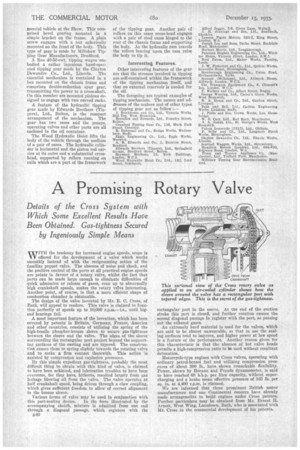

The tipping gear manufactured by the Truck and Tractor Appliance Co., Ltd., Trafford Park, Manchester, is unusual in that the hydraulic ram is disposed horizontally on the chassis. It operates through a cross-head coupled to a simple lever mechanism attached at its outer extremity to the underside of the body.

The ram cylinder is three-point suspended, mid the connection between the cross-head and the coupling rods is a knife-edge one, so that ample provision is made for the inevitable stressing of the body which occurs when tipping on uneven ground or dislodging an unevenly distributed load. A feature of the mechanism is the automatic opening of the door, either side or end, when the gear tips.

The Sentinel Apparatus.

One of the exhibits on the Sentinel stand at the Commercial Motor Show embodied a tipping gear of the hydraulic type. On a steam wagon, of course, the facility for operating an hydraulic gear is already available in the boiler pump. Manipulation of a small hand wheel on the off side of the chassis connects the boiler pump with the hydraulic ram cylinder. .

A by-pass valve operated within the cab diverts the water, and directs it back into the tank when the body is fully tipped. To lower, the ram cylinder is put into direct connection with the tank, and the water allowed slowly to return. The address of the Sentinel Waggon Works, Ltd., is Shrewsbury.

A. simple form of hand-operated mechanical gear, known as the Millshaw, was embodied in a Morris-Cona

inerciaI vehicle at the Show. This compriseti bevel gearing mounted in a simple bracket on the frame. A plain screw engages with a nut spherically mounted on the front of the body. This type of gear is made by Millshaw Tipping Gear Manufacturers, Bradford.

A Reo 40-50-ewt tipping wagon embodied a rather ingenious hand-operated tipping gear made by the Clayton Dewandre Co., Ltd., Lincoln. The essential mechanism is contained in a box mounted on the chassis frame and nomPriscs double-reduction spur gear, transmitting the power to a cross-shaft. On this member are mounted pinions designed to engage with two curved racks.

A feature of the hydraulic tipping gear made by Edwards Brothers (Tippers), Ltd., Bolton, Is the compact arrangement of the mechanism. The gear has two rams and the pumps, operating valves and other parts are all enclosed in the oil container.

The Wood Hydraulic Hoist lifts the body of the vehicle through the medium of a pair of cams. The hydraulic cylinder is horizontal and the piston rod carries at its outer end a substantial crosshead, supported by rollers running on rails which are a part of the framework of the tipping gear. Another pair of rollers on this same cross-head engages with a pair of steel cams hinged to the rear of the chassis frame and supporting the body. As the hydraulic ram travels the rollers bearing upon the cam raise the body to tip it.

Interesting Features.

Other interesting features of the gear ere that the stresses involved in tipping are self-contained within the framework of the tipping mechanism itself, and that no external reservoir is needed for the oil.

The foregoing are typical examples of tipping mechanism. The names and addresses of the makers and of other types

of tipping gear are as follow:—

J. Brockhouse and Co.. Ltd., Victoria Works, Hilt Top, West Bromwich.

Droningly and Edwards, Ltd., Foundry Street, Bolton.

Crawford Tipping Gear Co., 128, Much Park Street. Coventry. It. Disturnal and Co., Bridge Works, Wednesbury, Staffs. Eagle Engineering Co., Ltd., Eagle Works, Warwick, A. R. Edwards and Co., 1, Brewton Street, Bradford.

Edwards Brothers (Tippers), Ltd., Springfield !Garage, Bradford Street, Bolton. Heywood Brothers, 15, York Buildings, Loudon, W.C.2. Wood Hydraulic Hoist Co., Ltd., 182, Lord Street, Southport.

Alfred Jagger, 5-8, Green Lane, Walsall.

J. IL Jennings and Son, Ltd., Sandbach, Cheshire.

Lawson Pigott Motors, 320-2, King Street, London, W.6.

Joseph Lea and Sous, Dyehe Street, Rochdale Road, Alain-hotter,

Herbert Monis, Ltd., LoughisDreugh, Paterson Hughes Engineering Co., Ltd., Windsor House, Victoria Street, London, 8.W.1. Noel Paton, Ltd., Mater Works, Farriley,

J. W. Pickavant and Co., Ltd., Quikko Works, Granville Street, Birmingham.

Spenborough Engineering Co., Union Road, Heckmondwike, Yorks.

Spencer iMelksliam), Ltd„ Aldwych House, Aldwych, London, W.C.2.

'The Transport Equipment Co., 4, clement's Inn, London, W.C.2.

F. Walters and Co., Albert Street, Rugby. George Wearing, Ltd., Carter's Green Work, West Bromwich.

It. A. Dyson and Co., Ltd., Grafton Street, Liverpool.

Take and Bell, Ltd., Carlton Ell gineering Works, Lichfield, Staffs.

J. Perks and Son, Crown Works, Lye, Stow. bridge.

W. E. Cary, Ltd., Red Bank, Manrbester.

A. A. James, Ltd., St. George's Works, West Bromwich.

Falcon Ironworks (1913). Ltd. Oldham. F. Selby and Co., Ltd., Lcingruore Street Works. Birmingham_ Clayton Dewandre Co„ Ltd., Titanic Works, Lincoln, Sentinel Waggon Works, Ltd., Shrewsbury. Hamilton Motors ;London), Ltd., 466-490, Edgware Road, London, W.2. Truck and Tractor Appliance Co. (Mao. Chester), Ltd., Trafford Park, Manchester.

Millshaw Tipping Gear Mannfactur.ers, Brad. ford.