Strength and Neatness in

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

GOODS BODY CONSTRUCTION

Various Methods of Making Body Sides and Systems of Attachment. The Plank, Open and Panelled Types Described Our Body building Expert Deals with Constructional Features of Types of Body that are Widely Used for the Transport of Goods

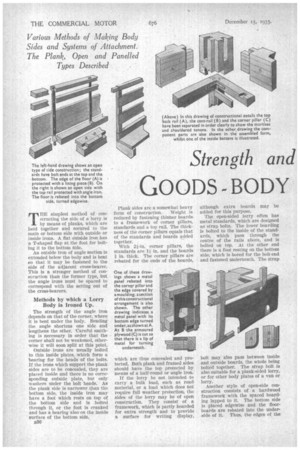

TRE simplest method of constructing the side of a lorry is by means of planks, which are held together and secured to the main or bottom side with outside or Inside irons. A flat outside iron has a T-shaped flap at the foot for bolting it to the bottom Side.

An outside iron of angle section is extended below the body and is bent so that it may be fastened to the side of the adjacent cross-bearer. This is a stronger method of construction than the former type, but the angle irons must be spaced to correspond with the setting out of the cross-bearers.

Methods by which a Lorry Body is Ironed Up.

The strength of the angle iron depends on that of the corner, where It is bent under the body. Bending the angle shortens one side and lengthens the other. 'Careful smithing is necessary in order that the corner shall not be weakened, otherwise it will soon split at this point.

Outside irons are usually bolted to thin inside plates, which form a bearing for the heads of the bolts. If the irons which support the plank sides are to be concealed, they are placed insi(le and there is no corresponding outside plate, but only washers under the bolt heads. As the plank side is narrower than the bottom side, the inside iron may have a foot which rests on top of the bottom side and is bolted through it, or the foot is cranked and has a bearing also on the inside surface of the bottom side.

3841 Plank sides are a somewhat heavy

form of construction. Weight is reduced by fastening thinner boards. to a framework of corner pillars, standards and a top rail. The thickness of the corner pillars equals that of. the standards and boards added together. .

With 24-in. corner pillars, the standards are I in. and the boards in. thick. The corner pillars are rebated for the ends of the boards, which are thus concealed and protected. Both plank and framed sides should have the top protected by means of a half-round or angle iron.

If the lorry be not intended to carry a bulk load, such as road material, or a load which does not require full weather protection, the sides of the lorry may be of open construction. They consist of a framework, which is partly boarded for extra strength and to provide a surface for writing display,

although extra boards may be added for this purpose.

The open-sided lorry often has metal standards, which are designed as strap bolts. The lower boarding is bolted to the inside of the standards, which pass through the centre of the rails above, and is bolted on top. At the other end there is a foot resting on the bottom side, which is bored for the bolt-end and fastened underneath. The strap bolt may also pass between inside and outside boards, the whole being bolted together. The strap bolt is also suitable for a plank-sided lorry, or for other body plates of a van or lorry.

Another style of open-side construction consists of a hardwood framework with the spaced boarding lapped to it. The bottom side is placed edgewise and the floorboards are rebated into the underside of it. Thus, the edges of the

floor are well protected. If the floor be laid on top of the bottom side in the usual manner, the edge should be protected by means of a fillet.

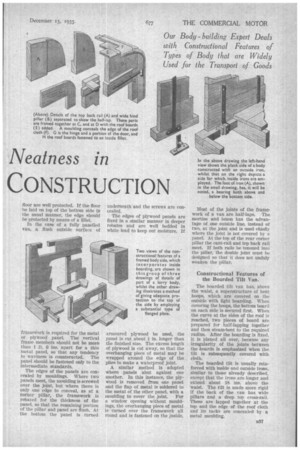

In the case of a fully panelled van, a flush outside surface of

framework is required for the metal Or plywood panel. The .vertical frame members should not be more than 1 ft. 6 ins, apart for a thin inetal panel, so that any tendency to waviness is counteracted. The panel should be fastened only to the intermediate standards.

The edges of the panels are concealed by mouldings. Where two panels meet, the moulding is screwed over the joint, but where there is only one edge to conceal, as at a corner pillar, the framework is rebated for the thickness of the panel, so that the remaining portion of the pillar and panel are flush. At the bottom the panel is turned underneath and the screws are concealed.

The edges of plywood panels are fixed in a similar manner in deeper rebates and are well bedded in white lead to keep out moisture. If armoured plywood be used, the panel is cut about in. longer than the finished size. The excess length of plywood is cut away, so that the overhanging piece of metal may be wrapped around the edge of the plies to make a waterproof joint.

A similar method is adopted where panels abut against one another. In this instance, the plywood is removed from one panel and the flap of metal is soldered to the metal of the other panel, with a moulding to cover the joint. For a window opening without mouldings, the overhanging piece of metal is turned over the framework all round and in fastened on the inside.

Most of the joints of the framework of a van are half-laps. The mortise and tenon has the advantage of one outside line, Instead of two, at the joint and is used chiefly where the joint is not covered by a panel. At the top of the rear corner pillar the cant-rail and top back rail meet. If both rails be tenoned into the pillar, the double joint must be designed so that it does not unduly weaken the pillar.

Constructional Features of the Boarded Tilt Van.

The boarded tilt van has, above the waist, a superstructure of bent hoops, which are covered on the outside with light boarding. When covering the hoops, the bottom board on each side is secured first. When the curve at the sides of the roof is reached, two pieces of board are prepared for half-lapping together and then steam-bent to the required radius. After the boarding is fixed, it is planed all over, because any irregularity of the joints between the boards is emphasized when the tilt is subsequently covered with cloth.

The boarded tilt is usually reinforced with inside and outside irons, similar to those already described, except that the irons are longer and extend about 18 ins, above the waist. The tilt is made more rigid if the back of the van has wide pillars and a deep top cross-rail. These are lapped together at the top and the edge of the roof cloth and its tacks are concealed by a metal moulding.