MODERN GREASE-GUN LUBRICATION.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

The Different Methods Employed in the Latest and Most Popular Method of Lubricating Non-rotating Moving Parts.

TNTIL comparatively recently grease lubrication has been

kJ looked upon 'by many of the most experienced motor engineers as an unsatisfactory system. This opinion was not formed* without good reasons, chiefly unscientifically constructed lubricators and poor or unsuitable grease.

The grease gun of to-day is a totally different thing from the old screw-down lubricator, which was not able to exert a Pressure of more than a few pounds to the square inch to

drive the grease, whereas grease guns are now obtainable which will exert a pressure normally of some MO lb. to 700 lb., whilst when one is fitted with "booster," " intendder," or compound piston, a pressure of 4,000 lb. to 5,000 lb. can be obtained, which is sufficient to flush out the most obstinate case of clogged-up bearing. With regard to the grease 'itself, much improvement has been recently made. In the past, grease of too hard a grade was used, whereas, to-day, what is called a solidified oil is used, which has the power of creeping and thus finding its way more readily to the place where it is required than the older greases which almost had the consistency of butter. Quite apart from this, the greases sold by the makers of the various systems are real lubricants, whereas the unbranded so-called greases of the past were often largely composed of earthy matter which had no lubricating qualities. The methods of connecting the gun to the nipple, the nipple itself and the aCaptets have all received attention.

Another and most important development is in the method of filling the gun, as formerly one pushed the grease into the

barrel as best one could, but now means are provided whereby the barrel can be filledwith solid grease, without air, in a few seconds, and in some instances the container itself is attached to the gun and the grease drawn from it by vacuum.

Proper fittinjs are provided to hold the gun in a convenient place on the vehicle, so as to be free from damage.

At one time the gun was allowed to lie in a toolbox with heavy articles, which often dented it and rendered it useless.

The lubrication of such parts as shackle pins, brake and steering cannections, universal joints, etc., may seem to those who have not had experience in maintenance to be a trivial matter, but in reality the poor means provided in the past for the lubrication of such parts was responsible for much of the high expenditure in replacement parts in respect of many fleets.

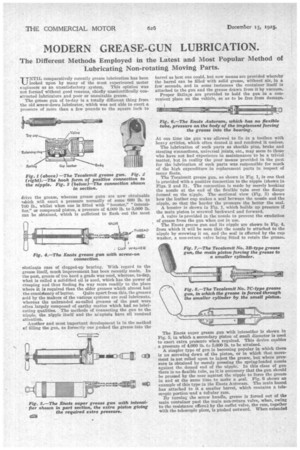

The Tecalemit grease gun, as shown in Fig. I, is one that is provided with a positive connection to the nipple (shown in Figs. 2 and 3). The connection is made by merely hooking the nozzle at the end of the flexible tube over the flange formed on the ripple. The sectional view (Fig. 3) shows how the leather cup makes a seal between the nozzle and the nipple, so that the harder the pressure the better the seal.

A booster is shown in Fig. I, which builds up pressure if the main piston is screwed backward and forward.

A valve is provided in the nozzle to prevent the exudation of grease from the gun when not in use.

The Enots grease gun and its nipple are shown in Fig. 4, from which it will be seen that the nozzle is attached to the nipple by screwing it on, and the seal is effected by the cup washer, a non-return valve being fitted to retain the grease.

The Enots super grease gun with intensifier is shown in Fig. 5, in which a secondary piston of small diameter is used to exert extra pressure when required. This device enables , a pressure of 4,000 lb. to 5,000 lb. to be attained. A simpler type of gun is becoming popular in which there is no screwing down of the piston or in which that movement is not relied upon to inject the grease, but where pressure is obtained by merely pressing the spring-loaded nozzle against the domed end of the nipple. In this class of gun there is no flexible tube, as it is necessary that the gun should be pressed by the user against the nipple to force the grease in and at the same time to make a seal. Fig. 6 shows an example of this type in the Enots Autoram. The main barrel has attached to it a smaller barrel, which contains a telescopic portion land a tubular ram. By turning be screw handle, grease is forced out of the main container past the main non-return valve, when, owing to the resistance offered by the outlet valve, the ram, together with the telescopic piece, is pushed outward. When extended

frilly, an automatic cut-off valve comes into action. To force the grease to the part requiring lubrication the ram is placed on the conical nipple, the orifice of which is normally sealed by a ball valve. A sharp push suffices to eject the grease displaced by the ram entering the high-pressure chamber.

The pressure in the latter reaches 4,000 lb. to 5,000 lb. per square inch, according to the force exerted. Another simple form of this type is the Tecalemit No. 3B (Fig. 7), in which a main piston forces the grease to a smaller -piston, which is held ir a perforated bridge. A spring-controlled telescopic portion carries at its outer end a ball valve, and if the nozzle be pressed on the dome-shaped nipple, a sharp push will force the grease contained in the smaller cylinder into the nipple at great pressure. A still simpler form is that of the Tecalemit No. 7C (Fig. 8), in which the grease is, forced into the small cylinder by the small plunger, which, on its return by means of the spring, causes a vacuum in the main cylinder which induces the following piston to descend as each charge of grease is delivered.

The Wakefield ram grease gun is one of the simplest, as there is no main cylinder, a tin of the company's Castrolease being ussd as a ecntainer. Fig. 9 shows he device in use and Fig. 10 gives a sectional view of it. A tin of grease is used as the main container and the three arms of the sun are attached to it as shown. The ram consists of a cylinder (A), which is closed at the top end and is provided with inlet ports at the bottom. In the end of the ram (B), which Works in the cylinder, is a spring-loaded ball valve (C), which Closes on the suction stroke and opens on the delivery to allow the passage of grease.

When pressure is applied to the canister the ram is forced past the inlet ports up to the top end of the cylinder, and when the pressure is released a coiled spring (D) returns the ram to the other end of the cylinder, thus causing a vacuum which sucks the grease from the canister by way of the annular space (E) between the cylinder wall and the connecting piece (F) and thence through the inlet ports to the cylin der. When the main ram is again forced up the cylinder the inlet Ports are closed, the ball valve t the end of the ram opens and the contents of the cylinder are forced down to the nipple to be lubricated.

Methods of Filling.

The Tecalemit method of filling is first to remove the end of the gun and to place it over the orifice in the metal disc inside the tin of grease, then to press downward so that a column of grease rises into the gun. A lateral movement will cut off this column flush with the disc as shown in Fig. 12. The Enots Method is shown in Fig. 11, which consists at a four-bladed instrument with a piston with four slots to take the blades. This filler is forced into a tin of grease and turned round co as to fill the spaces between the ...lades with grease. It is then inserted in the gun and the slotted piston held down by being screwed to the barrel. A few turns to the left will release this.

The Wakefield. of course, requires no tilling, as the actual canister itself forms the main container, and is thrown away when empty.

Fig. 14 shows a few of the adapters which are made to enable these systems to be adapted to almost any position in any make of chassis, whilst Fig. 13 shows a typical means of carrying a grease gun in clips for the purpose. It should be a matter of instruction to drivers that tItt grease gun be not mixed with other tools.