A Morris Auxiliary Gearbox

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

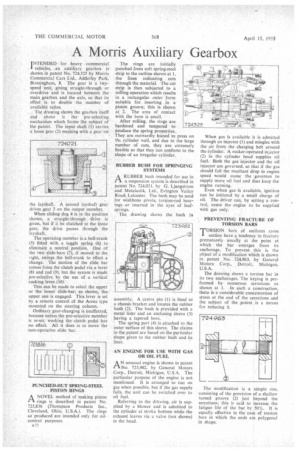

PTENDED for heavy commercial vehicles, an auxiliary gearbox is shown in patent No. 724,325 by Morris Commercial Cars Ltd., Adderley Park, Birmingham, 8. The gear is a twospeed unit, giving straight-through or overdrive and is located between the main gearbox and the axle, so that its effect is to double the number of available ratios.

The drawing shows the gearbox itself and above it the pre-selecting mechanism which forms the subject of the patent. The input shaft (I) carries a loose gear (2) meshing with a gear on the layshaft. A second layshaft gear drives gear 3 on the output member.

When sliding dog 4 is in the position shown, a straight-through drive is given, hut if it be clutched to the loose gear, the drive passes through the layshaft.

The operating member is a bell-crank (5) fitted with a toggle spring (6) to eliminate a neutral position. One of the two slide-bars (7), if moved to the right, swings the bell-crank to effect a change. The motion of the slide bar comes from the clutch pedal via a lever (8) and rod (9), but the system is made pre-selective by the use of a vertical rocking lever (10).

This can be made to select the upper or the lower slide-bar; as shown, the upper one is engaged. This lever is set by a remote control of the Arens type mounted on the steering column.

Ordinary gear-changing is unaffected, because unless the pre-selective member is re-set, working the clutch pedal has no effect. All it does is to move the non-operative slide bar.

PUNCHED-OUT SPRING-STEEL PISTON RINGS

ANOVEL method of making piston rings is described in patent No. 723,836 (Thompson Products Inc., Cleveland, Ohio, U.S.A.). The rings so produced are intended only for oilcontrol purposes.

a 12 The rings are initially punched from soft spring-steel strip to the outline shown at 1, the lines indicating cuts through the material. The cut strip is then subjected to a roiling operation which results in a rectangular outer form suitable for inserting in a piston groove; this is shown at 2. The area of contact with the bore is small.

After rolling, the rings are hardened and tempered to produce the spring properties. They are outwardly biased to press on thc cylinder wall, and due to the large number of cuts, they are extremely flexible so that they can conform to the shape of an irregular cylinder.

RUBBER BUSH FOR SPRINGING SYSTEMS

ARUBBER bush intended for use in a suspension system is described in patent No. 724,021. by G. Ljungstrom and Metalastik, Ltd., Evington Valley Road, Leicester. The bush may be used for wishbone pivots, torsion-rod bearings or inserted in the eyes of leafsprings.

The drawing shows the bush in assembly. A centre pin (1) is fixed to a chassis bracket and locates the rubber bush (2). The bush is provided with a metal liner and an enclosing sleeve (3) having a tapered bore.

The spring part (4) is attached to the outer surface of this sleeve. The claims in the patent are based on the particular shape given to the rubber bush and its liner.

AN ENGINE FOR USE WITH GAS OR OIL FUEL .

AN unusual engine is shown in patent No. 723,982, by General Motors Corp., Detroit, Michigan, U.S.A. The particular purpose of the engine is not mentioned. It is arranged to run on gas when possible, but if the gas supply fails, the unit can be switched over to oil fuel.

Referring to the dttwing, air is supplied by a blower and is admitted to the cylinder at stroke bottom while the exhaust leaves via a valve (not shown) in the head. When gas is available it is admitted through an injector (1) and mingles with the air from the charging belt around the Cylinder. A rocker-operated in;ector (2) in the cylinder head supplies oil fuel. Both the gas injector and the oil injector are governed, so that if the gas should fail the resultant drop in engine speed would cause the governor to supply more oil fuel and thus keep the engine running.

Even when gas is available, ignition can be initiated by a small charge of oil. The driver can, by setting a control, cause the engine to be supplied with gas only.

PREVENTING FRACTURE OF TORSION BARS

TORSION bars of uniform cross section have a tendency to fracturz prematurely usually at the point at which the bar emerges from its anchorage. To prevent this is the object of a modification which is shown in patent No. 724,963, by General Motors Corp., Detroit, Michigan, U.S.A.

The drawing shows a torsion bar in its two anchorages. The keying is performed by numerous serrations as shown at I. In such a construction. there is a considerable concentration of stress at the end of the serrations and the subject of the patent is a means for reducing it.

The modification is a simple one, consisting of the provision of a shallow turned groove (2) just beyond the serrations; this is said to increase the fatigue life of the bar by 50%. It is equally effective in the case of torsion bars in which the ends are polygonal in shape.