New Electric Brake for Long Descents

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

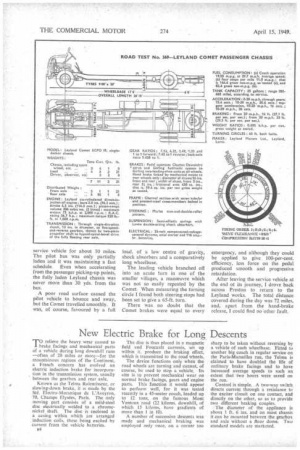

TO relieve the heavy wear caused to brake facings and mechanical parts of a vehicle during long downhill runs —often of 20 miles or more—for the mountainous regions of the Continent, a French concern has evolved an electric induction brake for incorporation in the transmission system, usually between the gearbox and rear axle.

Known as the Telma Ralentisseur, or slowing-down brake, it is made by the Ste. Electro-Mecanique de L'Aveyron, 70, Champs Elysdes, Paris. The only moving part consists of a mild-steel disc electrically welded to a chromenickel shaft. The disc is enclosed in a casing within whiCh are arranged induction coils, these being excited by current from the vehicle batteries.

134 The disc is thus placed in a magnetic field and Foucault currents, set up within it. produce the braking effect, which is transmitted to the road wheels.

The device functions only when the road wheels are turning and cannot, of course, be used to stop a vehicle. Its aim is to prevent mechanical wear on normal brake facings, gears and engine parts. This function it would appear to perform well, for it was tested recently in a 45-seater coach, loaded up to 12 tons, on the famous Mont Ventoux road (22 kiloms. downhill, of which 15 kiloms, have gradients of more than 1 in 10).

A number of successive descents was made and mechanical braking was employed only once, on a corner too

sharp to be taken without reversing by a vehicle of such wheelbase. Fitted to another big coach in regular service on the Paris-Marseilles run, the Telma is claimed to have doubled the life of ordinary brake facings and to have increased average speeds to such an extent that two hours were saved on the run.

Control is simple. A two-way switch directs current through a resistance to the exciter circuit on one contact, and directly on the other, so as to provide two different braking couples.

The diameter of the appliance is about 1 ft. 6 ins, and on most chassis it can be mounted between the gearbox and axle without a floor dome. Two standard models are marketed.