TOOLS FOR REPLACING PISTON RINGS.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Means Devised by Our Driver and Mechanic Readers for Performing an Awkward Job,

NEARLY ALL those drivers and mechanics who have written to us offering suggestions as to the most effective means for replacing. pistons and their rings in cylinders, with the least risk of lareakege of the rings, emphasize the fact that there is another risk which, in the ordinary way, has to he taken in the course of this operation; Whether This risk be onewhich is more serious than that of broken Tines is a matter for the individual to decide. -We are informed, at any rate, that whe»ever this operaticie is performed without the assistance of /me or other of the gadgets which we are about to describe, the fitter's fingers are sure to be trapped and injured somewhat.

One correspondent, " C.A.C.," of West minster, after emphasizing this important, matter, states that, according to his experience, it is difficult indeed to cumplete the overhaul of an engine without breaking one or more piston rings in the course of replacing the cylinders. The tool which he recommesufs as a valuable adjunct in connecticin with this operation, is 'a simple and no doubt an efficient one. He does not describe it, sending only a sketch, which we have had redrawn and reproduced. No doubt his remelt for this omission is in the first plebs that the tool is so simple awl his drawing is so clear that hardly any explanation is necessary, and hi the second that as the class of work with which readers of this page are accustomed to deal varies so much, particularly as to the dimensions of the engines, those who decide to make one of these tools will reel:tire to vary ,the dimensions in accordance with individual needs.

This correspondent does, however, thinkit advisable to draw attention to two important matters, notwithstanding the fact that they are clearly indicated

en his sketch. It is advisable," he states, referring to those portions of the teol which .embrace the piston, " to have." flanges at the top and bell mouthing on the bottom. The flange prevents the tool. Irene being jammed in the bell mouth of the cylinder, and the, bell mouth in the tool ensures its more ready engagement with the rings below."

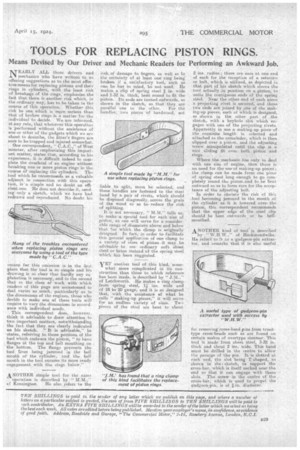

ANOTHER simple tool. for the same Operation is described by " M.M.." if Kensington. He also refers to the

risk of damage to fingers, as well as to the certainty of at least. one ring being broken if a, satisfactory tool, such as aim he has in mind, be not used. He makes a clip of spring steel iv wide and 1-32 in, thick, bent round to fit the piston. Its ends are turned outwards, as shown in the sketch, so that they are parallel one to the other. For the handles; two pieces -of hardwood, not

liable to split, must be selected, and these handles are fastened to the steel band by a pair of rivets, which should be disposed diagonally, across the grain of the wood So as toreduce the risk of splitting.

It is not necessary, " M.M." tells us, to make a special tool for each size of piston, as one will serve for a consider• able range of diameters above end below that for which the clamp is originally designed. In feet,. in order to facilitate this general application of one clamp to a variety of sizes ef piston .it may be advisable to use ordinary soft sheet steel or brass instead of the spring steel which has been suggested.

yET another tool of. this kind, somewhat. more complicated in its construction than those to which reference na.s been made, is described by "

of Letchworth. He makes a ring clamp from spring steel, 14 ins, wide and of 18 to 20 gauge, and it is so designed that, with the assistance of what he calls " making-up pieces," it will serve for an endless variety of sizes. Twe pieces of the steel are bent to about

2 ins. radius ; there are ears at one end of each for the reception of a setscrew or bolt, which is utilized, as depicted iii that part of his sketch which shows the tool actually in position on a piston, to unite the contiguous ends of the spring steel. Near the other end of each piece a projecting rivet is secured, and these. two ends are joined by one of the making-up pieces, each of which is designed, as shown in the other part of the sketch, With a keyhole slot which ert. gages with one of the projecting rivets. Apparently in use a making-up piece -of the requisite length is selected and attached to the renieinder, which is then slipped over a piston, and the adjusting screw manipulated until the clip. is', a nice sliding fit over both piston and

rings. • •

Where the mechanic has only to deal with one size of .engine' then there is no need for the use of making-up pieces ; the clamp can he made from one piece of spring steel lens,: enough to go completely round the piston.and to be bent outward sons to form ears for the acceptance of. the adjusting bolt.

In order to obviate the risk of this .fool becoming jammed in the mouth of the cylinder as it is lowered overthe piston, this correspondent recommends that the upper edge of the steel elip should be bent outwards or be bellmouthed.

ANOTHER kind of tool is described by "W.H.W.," of Hec.kmondwike. He refer:q• to it as a gudgeon-pin extractor, and remarks' that it is also useful for removing cross-head pins from trunktype cross-heads such as are found on certain makes of overtype steamer. This tool is made from sheet steel, 3-32 iii. thick and about 2 ins. wide. This Wed must be drilled in the centre to allow the pasea:ge of the pin. It. is slatted at each end,. the slot being T-shaped, as shown in the., sketch, to supPort the cross-bar, which is itself necked near the end so that it can engage with these slots. The screw in the centre of the cross-bar, which is used to propel the gudgeon-pin, is of diameter.