EACH TO HIS OWN

Page 122

Page 123

If you've noticed an error in this article please click here to report it so we can fix it.

• It is just 10 years since a "universal" standard for British-based demountablebody systems was developed by the Society of Motor Manufacturers and Traders. But there has been little sign of equipment built to this standard — apart from Abel, around whose design the standard was based.

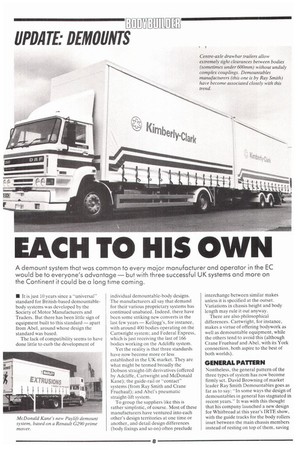

The lack of compatibility seems to have done little to curb the development of individual demountable-body designs. The manufacturers all say that demand for their various proprietary systems has continued unabated. Indeed, there have been some striking new converts in the last few years — Kellogg's, for instance, with around 400 bodies operating on the Cartwright system; and Federal Express, which is just receiving the last of 166 bodies working on the Adcliffe system.

Yet the reality is that three standards have now become more or less established in the UK market. They are what might be termed broadly the Dobson straight-lift derivatives (offered by Adcliffe, Cartwright and McDonald Kane); the guide-rail or -contact" systems (from Ray Smith and Crane Fruehauf); and Abel's pneumatic straight-lift system.

To group the suppliers like this is rather simplistic, of course. Most of these manufacturers have ventured into each other's design territories at one time or another, and detail design differences (body fixings and so on) often preclude interchange between similar makes unless it is specified at the outset. Variations in chassis height and body length may rule it out anyway.

There are also philosophical differences. Cartwright, for instance, makes a virtue of offering bodywork as well as demountable equipment, while the others tend to avoid this (although Crane Fruehauf and Abel, with its York connection, both aspire to the best of both worlds).

Nontheless, the general pattern of the three types of system has now become firmly set. David Browning of market leader Ray Smith Demountables goes as far as to say: "In some ways the design of demountables in general has stagnated in recent years." It was with this thought that his company launched a new design for Whitbread at this year's IRTE show, with the guide tracks for the body rollers inset between the main chassis members instead of resting on top of them, saving

around 100mm in floor height. However, the approach is very chassis-specific, and has not yet been repeated.

More of the development work these days is going into greater sophistication — and in particular into drawbar-trailer outfits making maximum use of load space. Several makers also report a lively market in bodies that can be lowered to ground level, Ray Smith has always been a strong advocate of this approach, endorsed especially by Adcliffe and McDonald Kane, which has gone a stage further by using ground-level techniques for a straight-lift system that incorporates extra hydraulics to allow operation entirely from within the cab. But director Michael Kane realises that: "It's a fairly complex and expensive solution to a problem."

While there is no sign of much departure from the established demountable-body designs, all the manufacturers are conscious of the implications of 1992, and especially of the Channel Tunnel. This is likely to give a spur to road-rail combined transport, which is already commonplace on the Continent. In particular, it is likely to stimulate new demand for the so-called "European" demountable body.

This is similar to an ISO container, but has various other special features. Most of the European examples are built to West German DIN standards 70/013 and 70/018. These specify body lengths, overall and demounted height. They also stipulate braced pull-out legs and twistlock fixings at ISO 6,1m (20ft) centres.

In the UK, the Abel system comes closest to this standard — at least visually — although the standard allows for guide-rail type bodies too, as long as the roller-box at the front can be retracted. But the DIN standard is a lot heavier and more solid than UK systems. Abel's managing director Mike Tweddle says: "The weight penalty over our standard system could be 250kg in the chassis equipment and 500kg in the body baseframe." A figure of a tonne is often mentioned. The extra weight is largely involved in meeting more abrupt bodylocation methods and in withstanding strength tests required for railway approval.

"An existing Abel chassis could probably pick up a DIN body without modification, which is a step in the right direction," says Tweedle. Already Abel is supplying DIN bodies to Continental users through its York Group parent and, with some of its customers is examining the possibility of upgrading existing equipment to provide greater compatibility with it.

However, no standard is sacrosanct. The European CEN (Comitd Europeen de Normalisation) has already proposed slightly different body lengths from the DIN standard, and electrical giant Philips has shown that a big enough user can call its own tune. The so-called "Philips concept" low-build demounts use DIN fittings such as leg assemblies, but involve an ultra-low chassis (a 140mm height is stipulated). Ray Smith, which opened its own factory in Holland this year, is building both DIN-standard and Philips-standard equipment there, although after some initial excitement, interest among UK operators has lapsed somewhat.

As Bob Buckley of Adcliffe points out: -We guaranteed the strength of an installation at a 150mm height, which we could achieve using standard steel sections, but not at a 140mm height. That

meant a deviation even from the nonstandard Philips arrangement." Besides, not all UK hauliers investing in this equipment have won the hoped-for business from the Philips group.

So the UK market seems set to polarise between existing proprietary systems for domestic work, and relatively standard (but heavy) Euro-demountables for international work. It is, however, tantalising to reflect that while the thwarted SMMT standard was being developed all those years ago, another standard was on the Freight Transport Association's drawing board.

That offered the marvel of interchange between straight-lift and contact systems, and allowed some leeway in body-fixing positions. It might still give pointers to ways of learning to live with DIN? D by Peter Rowlands