A New Small Oil Engine:

Page 102

Page 103

Page 104

Page 105

If you've noticed an error in this article please click here to report it so we can fix it.

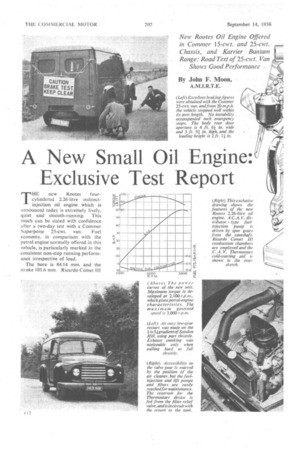

IExclusive Test Report ' THE new Rootes fourcylindered 2.26-litre indirectinjection oil engine which is announced today is extremely lively, quiet and smooth-running. This much can be stated with confidence after a' two-day test with a Commer Superpoise 25-ewt. van. Fuel economy, in comparison with the petrol engine normally offered in this vehicle, is particularly marked in the consistent non-stop running performance irrespective of load.

The bore is 84.14 mm. and the stroke 101.6 mm. Ricardo Comet III

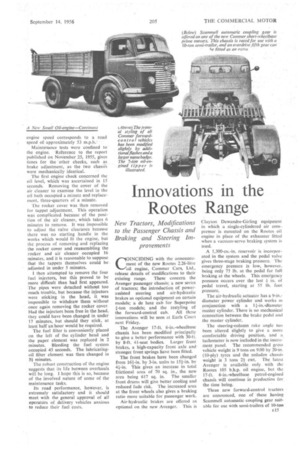

patent combustion chambers are used and, in many respects, the engine follows conventional design for this size of unit. It is, however, the first British production unit to employ a distributor-type fuelinjection pump as standard equipment.

A deep crankcase, in conjunction with three 21-in.-diameter main bearings, greatly reduces the possibility of crankshaft failures. The big ends run on 2.31-in.-diameter crankpins and the ends are split almost vertically to facilitate withdrawal of the pistons and connecting rods upwards through the bores. Lead-indium steel-hacked bearings are used throughout the crankshaft.

The C.A.V. DPA fuel-injection pump, driven through: spur gears from the camshaft, is lmotinted on the left of the cylinder block. This pump has much to be said in its favour. For instance, its simple

design and construction give low weight, small size and reduced cost. No calibration is required and the drive arrangements make for simple

installation in any unit. Its selflubricating and high-speed operation properties arc also attractive.

Because the reciprocating masses are only small and there are no springs in the assembly, the pump can be driven at 'high speed and has been tested at engine steeds' up' to 4,200 r.p.m. The driving torque is always positive and there' is, therefore, a reduced tendency for torsional vibration to occur. This allows the pump to be driven direct from the engine camshaft, as in the 'case of the Rootes unit.

Injection cannot take .place if the pump is rotated backwards, bectsise the port phasing becomes reversed and the internal transfer' pressure. This reduces any fear of the engine being able to run in reverse. A 'hydraulic governor is embodied in the design of the pump, this being the simplest type of governor offered with the DPA unit. Unlike other hydraulic governors, it consists of little more than a spring-loaded metering valve and adjustment is confiryx1 to one screw. The Pump is based on the Arnerican Hartford Machine Screw Company's design, which is being used extensively in the United States, and it has been adapted by C.A.V., Ltd., to suit the requirements of British and European engine designers.

Cold-starting difficulties are alleviated by the use of the new C.N.V. 285/1 Thermostart. This is a simple device fitted to the induction manifold which heats the air drawn into the cylinders when starting in low

ambient temperatures. It is controlled by a switch on the panel which, when operated, admits fuel from a small reservoir tank at a carefully controlled rate of flow, through a small wire coil.

Electrically Heated Coil

This coil is heated electrically and the fuel is vaporized as it flows along it. When the starter switch is depressed, air passes into the manifold and through the Thermostart burner. The vaporized fuel is thus ignited, burning with a powerful flame. This arrangement is much simpler and less costly than an individual heater plug in each combustion chamber.

The new engine has approximately the same external dimensions as the Commer 2.2-litre petrol engine, with which it is interchangeable. It is offered in all Commer 15-cwt. and 25-cwt. chassis and in the Karrier Bantam range. Similar mounting arrangements are employed and the engine, which has a 10-in.-diameter clutch, is used with a standard fourspeed synchromesh gearbox.

The test vehicle was a standard 9'-ft. 4-in.-wheelbase 25-cwt. van. It had covered' 800 miles before my test, so it was reasonably loose mechanically and a payload consisting of bags. of granite chippings, which totalled26.4 cwt, : had been

Plaeed in the body.

A weighbridge check showed that with driver and passenger aboard, the van weighed 3 tons 7 cwt„ of which I ton 2+ cwt. was imposed on the front wheels. The gross weight as tested was 2 cwt. above the manufacturers' recOnlinended figure, but I did riot'elect to.chatige it, as it. was the same as the weight of the petrol: engined 25-cwt. chassis which I tested last November.

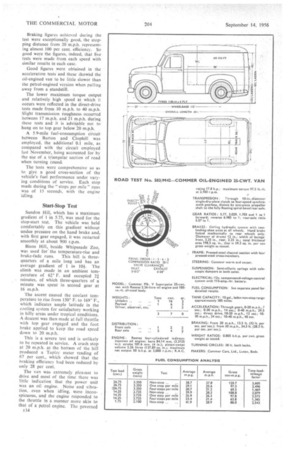

Braking figures achieved during the test were exceptionally good, the stopping distance from 20 m.p.h. representing almost 100 per cent. efficiency, So good were the figures, indeed, that five tests were made from each speed with similar results in each case.

Good figures were obtained in the acceleration tests and these showed the oil-engined van to be little slower than the petrol-engined version when pulling away from a standstill.

The lower maximum torque output and relatively high speed at which it occurs were reflected in the direct-drive tests made from. 10 m.p.h. to 40 m.p.h. Slight transmission roughness occurred between 17 m.p.h. and 21 m.p.h. during these tests and it is adviiable not to hang on to top gear below 20 m.p.h..

A -5.9-mile fuel-consumption circuit between Barton and Clophill was employed, the additional 0.1 mile, as compared with the circuit employed last November, being accounted for by the use of a triangular section of road when turning round.

The tests were comprehensive so as to giyc a good cross-section of the vehicle's fuel, performance under varying conditions of service. Each stop made during the "stops per mile" runs was of 15 seconds, with the engine idling.

Start-Stop Test

Sundon Hill, which has a maximum gradient of 1 in 5.75, was used for the stop-start test. The vehicle was held comfortably on this gradient without undue pressure on the hand brake and, with first gear engaged, it was restarted smoothly at about 900 r.p.m.

Bison Hill, beside Whipsnade Zoo, was used for the temperature-rise and

brake-fade runs. This hill is threequarters of a mile long and has an average gradient of 1 in 10+. The climb was made in an ambient ternperature of 62° F. and occupied 21, minutes, of which three-quarters of a minute was spent in second gear at 16 m.p.h.

The ascent caused the coolant temperature to rise from 150° F. to 169° F., which indicates ample latitude in the cooling system for satisfactory working in hilly areas under tropical conditions. A descent was then made at full throttle with top gear engaged and the foot brake applied to keep the road speed down to 20 m.p.h. •

This is a severe test and is unlikely to be repeated in service. A crash stop at 20 m.p.h. at the bottom of the hill produced a Tapley meter reading of 67 per cent., which showed that the braking efficiency had been reduced by only 28 per cent.

The van was extremely pleasant to drive and most of the time there was little indication that the power unit was an oil engine. Noise and vibration, even when idling, were inconspicuous, and the engine responded to the throttle in a manner more akin to that of a petrol engine. The governed

E14

engine speed corresponds to a road speed of approximately 53 m.p.h.

Maintenance tests were confined to the engine. Reference to the report published on November 25, 1955, gives times for the other checks, such as brake adjustment, as the two chassis were mechanically identical.

The first engine check concerned the oil level, which was ascertained in 15 seconds. Removing the cover of the air cleaner to examine the level in the oil bath occupied a minute and replacement, three-quarters of a minute.

The rocker cover was then removed for tappet adjustment, This operation was complicated because of the position of the air cleaner, which takes 6 minutes to remove. It was impossible to adjust the valve clearance because there was no starting handle in the works which would fit the engine, but the process of removing and replacing the rocker cover and reassembling the rocker and air cleaner occupied 16 minutes, and it is reasonable to suppose that the tappets themselves could be adjusted in under 5 minutes.

I then attempted to remove the four fuel injectors, but this proved to be more difficult than had first appeared. The pipes were detached without too much trouble, but because the injectors were sticking in the head, it was impossible to withdraw them without once again removing the rocker cover. Had the injectors been free in the head, they could have been changed in under 17 minutes, but should they stick, at least half an hour would be required.

The fuel filter is conveniently placed on the left of the cylinder head and the paper element was replaced in 2 minutes. Bleeding the fuel system occupied 45 seconds. The lubricatingoil filter clement was then changed in 34 minutes.

The robust construction of the engine suggests that its life between overhauls will be long. I hope this is so, because of the involved nature of some of the maintenance tasks.

Its road performance, however, is extremely satisfactory and it should meet with the general approval of all operators of delivery vehicles anxious to reduce their fuel costs.