AN ENTIRELY NEW BRITISH CHASSIS.

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

The Bristol, Designed Primarily for Passenger Work, but also Eminently Suitable as a Four-ton Lorry.

FEW :MANUFACTURERS have had better opportunity for studying those points requiring especial consideration in chassis designed for passenger carrying than the Bristol Tramways and Carriage Co., Ltd., whose chief offices are at Tramways Centre, Bristol. This

company commenced using motor omnibuses for their Bristol services in 1908, the first vehicles being Thornycrofts, which were followed by Fiats. At that time, however, chassis builders did not cater so well for the requirements of their customers as they do now, and the company decided to build chassis to meet their own requirements, and they have continued to do this since that time.

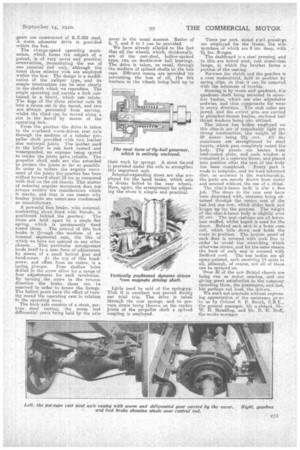

The post-war Bristol chassis, which is the one we aae about to describe, is the result of the great experience which the conqiany have obtained during the course of many years running with , chassis of their own design and con: structinn. Many of these chassis, fitted with 29-seater saloon omnibus bodies, are running in Bristol and to points con,siderable distances out. The first postwar chassis has been run in this way a distance of 197,000 miles, without an involuntary stop, and it shows remarkably few signs of wear at any point; for instance, the wheel bearings, all of which are double-row self-aligning ball bearings of Skefko make, have not had to be changed during the whole of this distance, and their employment for this purpose has thus been justified. So it is with-every other part of the chassis. Everywhere it is designed with a view to hard service, simplicity and lightness combined with strength. Gadgets

are not in favour, although the chassis is by no means devoid of novel features, but where these are incorporated they are of a simple, workmanlike nature and, in many cases, dispense with a large number of parts.

For our edification one of the new saloon buses was withdrawn from public service and placed at our disposal for a short trial. ran. The city of Biistol abounds in hills, some sufficiently steen fully to try the capabilities of an omnibus, and our trip included one of the most severe, of these hills. The engine shoWed plenty of life and ample pulling powers, as was demonstrated by a stop which was made at the worst part of the hill, after which the vehicle was able to start off very smoothly, and to get into second gear. As a matter of fact, the particular hill we tested bas been climbed on top gear by a similar bus.

The change-speed control, which is centrally situated, is extremely simple and very free in operation. During our short test we were much impressed by the coinfort ensured by the spring-back garden seats fitted on the bus. The carrying out of this springing is so simple that it is surprising that it has not been adopted on London's buses, The springs constitute the supporting

arms for the seat backs; they are made from good quality material, and, although they will give easily a 4 in. movement, we understand that breakages seldom, if ever, occur.

The output programme for this chassis is 10 per week,. and this number will probably be augmented in the future; even now the company is able to give immediate delivery of a considerable number. The retail price of the chassis is £1,250, or, complete with •29-seater, specially constructed saloon bus body, E2J000, and with a 28-seater char-k

basics hotly, £1,750. The chassis are manufactured at _ the company's .fine motor works at Blislington, which were previously employed on the construction of Bristol aeroplanes, the char-a-banes bodies at the body works, not far from the former, and the saloon bus bodies at the Fitton aeroplane works, where they are constructed by the producers of that famous aeroplane, tho "Bristol -Fighter." We shall have more to say about the saloon bodies • later on, but would mention that they embody much

of the expeeience gained in the constmetion of aeroplane fusilages.

To return to the chassis, this is provided with a four-cylinclerecr engine with a bore and stroke of 4.1 ins. and 5i ins. respectively. It develops 48 b.h.p. at 1,400 r.p.m. The cylinders ale cast in pairs, and are of the L-headed type. The cylinder blocks are positioned closely together with a free water space between them, rendered watertight by a gasket. The water spacing is ample, particularly round the valves, and is carried well down the cylinders. .After repeated trials, the producers have proved that, properly carried out,

therrno-syphonic cooling weer circulation is eminently satisfactory. The circulating pipes have a bore of 4 ins.

throughout, and the radiator which is -of the cast aluminium header and bottom tank type, with a gilled tubular core, has ample water capacity, and presents adequate cooling surface. Incidentally, it is spring-mounted on the frame, and is thus isolated from any slight frame torsion which might occur ; the circulation of air through it is assisted by a cast aluminium threebladed fan, belt driven, and carried on an eccentric spindle to allow for adjustment of the latter: A 21 ins, nickel steel crankshaft, provided with three bearings, prevents crankshaft whip. All the main and bigend bearings have white . metal-lined bronze shells. The big-ends have four bolts, and the gudgeon pin is held firmly in the little-end. A Renold chain, 2.4 ins, wide, drives the timing gears, the adjustment being at the magneto end. Two east aluminium plates enclose the valves, which are provided with adjustable tappets and detachable valve guides.

The engine has three-peint suspension, being slung from a stamped steel engine bearer at the front end. This bearer forms part of the engine unit, and is removed with it when necessary.

A particularly neat type of governor, which is absolutely "fool-proof," and cannot be interfered with by the driver, is contained in the timing gearcase. It; consists of three large steel balls, which, as the engine speed increases, are thrown Outwards by centrifugal force, " and wedge back a steel disc, the inner face of which forms an inclined plane. A simple push-rod, _provided with a hardened steel end, 'presses against this plate, and is connected at the other end to a butterfly throttle, separate from the ordinary throttle, and contained in the intake manifold.

For lubrication, a gear pump, situated in the sump, and driven from the camshaft by means of a spiral gear, delivers oil to troughs under the connecting rods, the latter being provided with dippers. The surplus oil is taken by pipes can ied in the crankcase casting to each crankshaft and camshaft bearing, the used oil 'returning to the sump through a large filter, which can be removed for(

Cleaning without loss of oil. ,

The slow-running carburetter control lever, and that controlling the advance and retard, are held in a casting which forms the dashboard support for the steering pillar. One lever is positioned at each side of a hole _bored through this pillar, and between them is inserted. a stout spring, which butts up against steel discs bearing against leather frie

tion washers which prevent the levers from working loose under the influence of vibration.

The ignition leads are neatly carried in a. light, aluminium casting bolted to . the. top water connection; this connec tion is cored through for the purpose; and the wires are carried in rubber insulators inserted into these core holes.

The clutch consists of a saw steel centre gripped between two rings of Feroclo, one of. which is riveted direct on to the flywheel and the other to the ring which takes up the pressure of the clutch springs. The leverage of the clutch withdrawal mechanism and the pressure of the clutch springs is arranged so that the pressure required on the pedal to declutch is under 35 lb. Incidentally, the height of this pedal adjustable. The clutch shaft has a, splined end, which fits -into the splined, centre of the clutch member ; the latter' spigots into a-double-row Skefko bearing held in the flywheel. The splines on the clutch shaft are curved in the hori zontal plane, in order to give Ws member a certain amount of universal action. Between the clutch shaft, and the gearbox is a laminated steel universal joint.

Four speeds forward and a reverse are provided by the gearbox, which is

situated amidships, and upported at four points by brackets bolted into the channels of the side members. The

casing of the gearbox consists of a steel

casting split horizontally. Little can be said regarding its design except that the shafts are short and stout, and carried on ball bearings, and the wide

gears are constructed of li.-E.805 steel. A worm odometer drive is provided within the box.

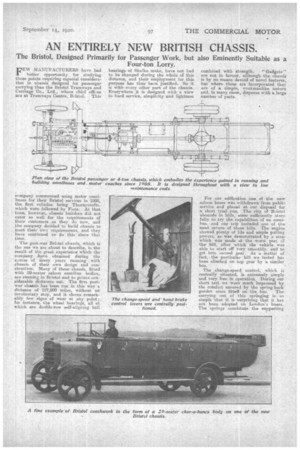

The change-speed operating mechanism, which forms the subject, of, a patent, is of very novel and practical .construction, necessitating the use of one external rod only, although the usual three selector rods are employed within the box. The design is a modification of the calliper type, and its simple construction can be seen clearly in the sketch which we reproduce. The single operating rod carries a fork contained in a barrel, which can rotate. The dogs of the three selector rods fit into a recess cut in the barrel, and two are always prevented from moving, whilst the third can be moved along a Slot in . the barrel by means of the operating fork.

From the gearbox the drive is taken to the overhead worm-driven rear axle through the medium of a tubular pro-. peller shaft provided with two leather disc universal joints. The leather used in the latter is oak bark tanned and waterproofed, no expense being spired to render the joints quite reliable. The propeller shaft ends are also extended to protect the joints so far as possible. In order to reduce the angular move. ment of the joints the gearbox has been shifted forward about 18 ins, as compared with that on the old chassis. This matter of reducing angular movement does not always receive the consideration which it merits, sod that is one reason why leather jOints are sometimes condemned. as .unsatisfactory.

A powerful foot brake, with externalcontracting shoes lined with Ferodo, is positioned 'behind the gearbox. The oboes are held apart by a single flat spring, which is permanently fixed round them. The control of this foot • brake is through the medium of an internal segmental cam, the like of which we have not noticed on any other

chassis. This particular arrangement lends itself to a neat form of adjustment by .means of a small helical gear and hand-screw. At the top of this handscrew, and offset from its centre, is a

'spring planger. Four shallow holes drilled in the screw allow for a range of four adjustments for each revolution. By turning the screw in the reverse direction the brake, sh,oes can to removed in order to renew the linings. The helical gears have the effect of turn. ing round the operating cam in relation to the operating lever. The back axle consists of a stout, pot. type steel casting, the warm and differential gears being held by the axlo cover in the usual manner. Ratios of 6, 7, and 8 to 1 can be provided. We have already alluded to the fact that all the wheels, which, incidentally, are of the cast-steel, hollow-spoked type, run on double-row ball bearings. The drive is taken, as usual, through the medium of splined shafts to the hub caps. Efficient means are provided for preventing. the loss of oil, the felt washers in the wheels being held up to

their work by springs. A stout tie-rod is provided under the axle to strengthen

this important unit. • Internal-expanding shoes are also employed for the hand brake, which acts on drums bolted to the rear wheels. Here, again, the arrangement for adjusting the shoes is simple and practical.

Little need be said of the springing. 'That it is excellent was proved durineonr trial trip. The drive is taken through the rear springs, and to prevent strain being thrown on the cardan joints of the propeller shaft a splinecl coupling is employed.

Three per cent. nickel sleel pressings are employed for the frame, the side members of which are 8 ins, deep, with. 2i ins. flanges. The dashboard is a steel pressing, and to this are bolted neat,' cast aluminium lamps, in which the bracket forms a portion of the casting. Between the clutch and the gearbox is a neat undershield, held in position by spring clips, so that, it can be removed with the minimum, of trouble. .

Steering is by worm and quadrant, the quadrant shaft being mounted in .eccentric bushes, which are also adjustable endwise, and thus compensate for wear in every direction. The stub _axles are jawed, and the swivel pins are carried in phosphor-bronze bushes, enclosed ball thrust washers being also utilized.

The Saloon bus bodies employed on this clras2is are of remarkably light yet strong construction, the weight of the 28 seater being 22i cwt. All the stanchions are strengthened by steel inserts, which pass completely round the body. The panels are beaten from lead-coated plate, and each window is contained in a separate frame, and placed into position after the rest of the body has been completed. Every part, made to template, and We were informed that, so accurate is the workmanship, the parts are merely drawn -from stores and erected without the use of a chisel.

The char-a-banes body is &SO a fine job. The doors to the rear seat have been dispensed with, entrance being obtained through the centre seat of the last but one row, which slides back and hinges Up for the purpose. The weight of the char-a-bancs body is slightly over 22 cwt. The seat cashions are all horsehair stuffed, whilst kapok is used for the doors. Behind each seat is a brass coat, rail, which falls dawn and holds the coats in position. The bottom panel -of each door is covered with cork lino in order to avoid the scratching which otherwise occurs and for the same reason the back of each seat is covered with Bedford cord. The bas bodies are all spray-painted, each receiving 14 boats in all, although, of course, not all of these can be sprayed on.

Over 30 of the new Bristol chassis are being run as motor coaches, and are giving great satisfaction _to the company operating them, the passengers, and last, but perhaps not least, the drivers.

We mint not conclude without expressing appreciation of the assistance given to us by Colonel S. E. Smith, C.B.E., the general manager, his a-sistant, Mr. W. H. &raffling, and Mr. D. IL Duff, the works manager.