Pressure System Improves Cooling Efficiency

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

THE performance of the cooling system of a motor-vehicle engine is commonly stated in terms of temperature difference, by which is implied the difference between the temperature at which the cooling fluid—usually water —boils, and the atmospheric shade temperature in which the vehicle is capable of operating. The temperature difference specified by the War Office, for example, is 110 degrees F., and as water boils at 212 degrees F. under atmospheric pressure, this means that vehicles can operate in atmospheric shade temperatures up to 102 degrees F., without loss of water.

The efficiency of a cooling system depends upon the weight of air which can be brought into intimate contact with a unit area of radiating surface, in unit time. As radiator areas are limited by considerations of space, weight and economy, it follows that high-efficiency cooling generally involves considerable expenditure of power in forcing air through the radiator block at the requisite velocity.

This, however, is not the only disadvantage, for excessive cylinder wear often results from unnecessary overcooling when vehicles, which are capable of working in tropical climates, are called upon-to operate under less onerous conditions.

It is clearly the function of the cooling system to ensure that the vehicle shall be capable of operating under conditions of the highest possible atmospheric shade temperature, without loss of water. By raising the boiling point of the water, and with no other alteration to the cooling system, this object can be readily achieved.

In the example mentioned in the first paragraph, it was shown that the maxi mum atmospheric shade temperature in which the vehicle can operate is 102 degrees F. But, if the boiling point of the water be increased to, say, 232 degrees F., then the temperature in which the vehicle could operate, without loss of water, would become 122 degrees F., a material gain in cooling efficiency.

It is upon this principle that the British Thermostat Co., Ltd., Windmill Road, Sunbury-on-Thames, Middlesex, has designed its PLV valve. This valve allows the pressure in the cooling system to be increased by a few lb. per sq. in., by which means the boiling point of the cooling water caa be raised by some 20 degrees F., depending upon a simple adjustment provided in the valve.

When the system cools down, however, a partial vacuum is created within it with the result that it is subjected to atmospheric pressure on the outside. To avoid the risk of trouble with the radiator header tank, rubber hose and so forth, under this condition, a simple vacuum relief arrangement is incorporated in the valve.

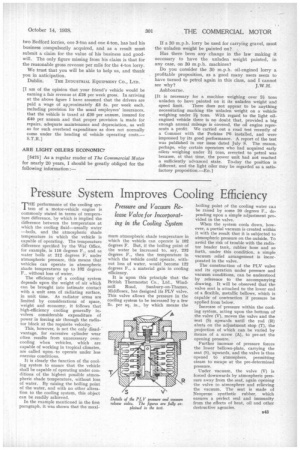

The construction of the PIN valve and its operation under pressure and vacuum conditions, can be understood by reference to the accompanying drawing. It will be observed that the valve seat is attached to the lower end of a flexible, metallic bellows, which is capable of contraction if pressure be applied from below.

Increase of pressure within the cooling system, acting upon the bottom of the valve (V), moves the valve and the seat (S) upwards until the rod (R) abuts on the adjustment stop (T), the projection of which can be varied by means of a screw (A), to pre-set the opening pressure.

Further increase of pressure forces the lower bellows-plate, carrying the seat (S), upwards, and the valve is thus opened to atmosphere, permitting steam to escape at the pre-determined pressure.

Under vacuum, the valve (V) is forced downwards by atmospheric pressure away from the seat, again opening the valve to atmosphere and relieving the vacuum. The seat is made of Neoprene synthetic rubber, which ensures a perfect seal and immunity from the effects of heat, oil and other destructive agencies.