THE DESIGN OF ATTR, :TIVE DELIVERY VANS

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

STANDARDIZED bodywork often meets the requirements of the operator wishing to buy a delivery van, but in other instances, the body must have certain internal dimensions, or must be designed to carry all or part of the load in a particular manner, such as on trays or shelves. Again, some operators specify extra door-openings, or showcases on each side for displaying the goods, whilst it is by no means unusual for a distinctive design to be demanded which shall not detract from the practical utility of the vehicle concerned.

B38 When the body is to be specially built, the customer naturally wishes to see what the proposed design will look like before giving his orders, and the coachbuilder, therefore, prepares a scale drawing. The chassis may have been definitely selected, but in other cases the operator may wish to see how the body will appear when mounted on each of two or three different makes of chassis of similar load-capacity. Such chassis are not identical as to body space, whilst the varying disposition of the wheelbase, the outline of the bonnet and other considerations have the effect of modifying the appearance. The regulation is now in force that the overhang of the body beyond the rear-axle centre must not be more than 50 per cent. of the wheelbase. This stipulation may appear no more restrictive on body design than the previous regulation of 7-24ths of the overall length of the vehicle, but whether this is so depends chiefly on the relation of the back of the cab to the axle centres, Streamlining is still much in favour, but often the operator wants some new disposition of mouldings, or areas of panelling, incorfiorated in the design. When the body has a Luton-type front, a novel appearance may be imparted to the roof by introducing a curve at the back of the cab door, similar to that in front. This rear curve would join the waterguttering or cant-rail moulding. Then the lower part of the body could be decorated with an area of panelling, the outline of which would be a curve of shape similar to the paddlebox panel, but of larger radii.

Unlike the usual waist moulding, which curves downwards at its rear end, this moulding would curve upwards, a few inches beyond the cab door, thus repeating the curve at the roof and that of the enlarged paddlebox panel, after which it would continue horizontally at the door-top level.

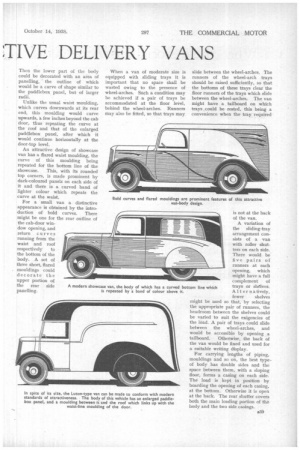

An attractive design of showcase van has a flared waist moulding, the curve of this moulding being repeated for the bottom line of the showcase. This, with its rounded top corners, is made prominent by dark-coloured panels on each side of it and there is a curved band of lighter colour which repeats the curve at the waist. When a van of moderate size is equipped with sliding trays it is important that no space shall be wasted owing to the presence of wheel-arches. Such a condition may be achieved if a pair of trays be accommodated at the floor level, behind the wheel-arches. Runners may also be fitted, so that trays may slide between the wheel-arches. The runners of the wheel-arch trays should be raised sufficiently, so that the bottoms of these trays clear the floor runners of the trays which slide between the wheel-arches. The van might have a . tailboard on which trays could be rested, this being a convenience when the tray required

is not at the back of the van.

A variation of the sliding-tray arrangement consists of a van with roller shutters on each side. There would be five pairs of runners at each opening, which might have a full complement of trays or shelves. Alternatively, fewer shelves might be used so that, by selecting the appropriate pair of runners, the headroom between the shelves could be varied to suit the exigencies of the load. A pair of trays could slide between the wheel-arches, and would be accessible by opening a

tailboard. Otherwise, the back of the van would be fixed and used for a suitable writing display.

For carrying lengths of piping, mouldings and so oh, the best typeof body has double sides and the space between them, with a sloping floor, forms a casing on each side. The load is kept in position by boarding the opening of each casing, at the bottom. Otherwise it is open at the back. The rear shutter covers both the main loading portion of the body and the two side casings.