The Crossley 56-seater Chassis Much Improved

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

SINCE we last described the doubledeck oil-engined bus chassis built by Crossley Motors, Ltd., Gorton, Manchester, modifications have been made, affecting practically the whole machine. As a result, the company's latest 56-seater may be regarded as virtually a new model.

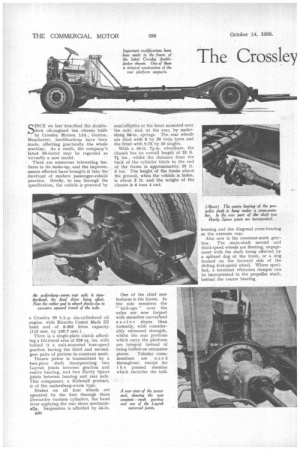

There are numerous interesting features in its make-up, and the improvements effected have brought it into the forefront of modern passenger-vehicle practice. Briefly, to run through the specification, the vehicle is powered by a Crossley 99 b.h.p. six-cylindered oil engine, with Ricardo Comet Mark III head and of 8.365 litres capacity (113 mm. by 139.7 mm.).

There is a single-plate clutch affording a frictional area of 228 sq. ins, with behind it a unit-mounted four-speed gearbox having the third and secondgear pairs of pinions in constant mesh.

Thence power is transmitted by a two-piece shaft incorporating two Layrub joints between gearbox and centre bearing, and two Hardy Spicer joints between bearing and rear axle. This component, a Kirkstall product, is of the underslung-worm type.

Brakes on all four wheels are operated by the foot through three Dewandre vacuum cylinders, the hand lever applying the rear shoes mechanically. Suspension is afforded by 44-in.

Bat) semi-elliptics at the front mounted over the axle, and, at the rear, by underslung 58-in. springs. The rear wheels are shod with 9 by 20 twin tyres and the front with 9.75 by 20 singles.

With a I6-ft. 74-in. wheelbase, the chassis has an overall length of 25 ft. 74 ins., whilst the distance from the back of the cylinder block to the end of the frame is approximately 20 ft. 6 ins. The height of the frame above the ground, when the vehicle is laden, is about 2 ft. and the weight of the chassis is 4 tons 4 cwt.

One of the chief new features is the frame. In the side members the " kick-ups" over the axles are now formed with smoother curvestand easier slopes than formerly, with considerably enhanced strength, whilst the rear portions which carry the platform are integral instead of being bolted-on extension

pieces. Tubular crossmembers are used throughout, except for t h e pressed member which encircles the bell

housing and the diagonal cross-bracing at the extreme rear.

Also new is the constant-mesh gearbox. The main-shaft second and third-speed wheels are floating, engagement with the shaft being effected by a splined dog at the front, or a dog formed on the forward side of the sliding first-speed wheel. Where specified, a torsional vibration damper can be incorporated in the propeller shaft, behind the centre bearing.

Incidentally, the transmission line is offset, the final drive being well over to the off side. The engine, however, 3S mounted in the position most desirable on general grounds and the universals look after the small angularity, which they are well capable of doing.

On this Crossley, vacuttm for brake operation is raised by engine suction, and a recent innovation is in connection with the Means adopted for restricting the air intake for this purpose. There is a throttle valve in the air intake capable of closing the aperture completely. This is actuated by the accelerator pedal, closing when the pedal is released.

On the engine side of the valve is an adjustable orifice admitting air for ticking over to the manifold when the main intake is closed. There is a lostmotion device in the coupling between pedal and valve, to give a slight lag in opening when the pedal is depressed and a prompt closing when it is released.

Another noteworthy brake detail is an improved easy adjusting device for both hand and foot systems.

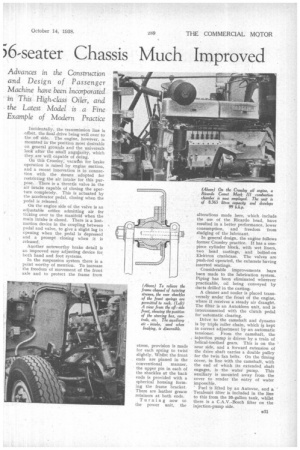

In the suspension system there is a point worthy of mention. To increase the freedom of movement of the front axle and to protect the frame from alterations made here, which include the use of the Ricardo head, have resulted in a better performance, lower consumption, and freedom from sludging of the lubricant.

In general design, the engine follows former Crossley practice. It has a onepiece cylinder block, with wet liners, two head castings, and bolted-on Elektron crankcase. The valves are push-rod operated, the exhausts having inserted seatings.

Considerable improvements have been made to the lubrication system. Piping has been eliminated wherever practicable, oil being conveyed by ducts drilled in the casting.

A cleaner and cooler is placed transversely under the front of the engine, where it receives a steady air draught. The filter is an Autokleen unit, and is interconnected with the clutch pedal for 'automatic clearing.

Drive to the camshaft and dynamo is by triple roller chain, which is kept in correct adjustment by an automatic tensioner. From the camshaft, the injection pump is driven by a train of helical-toothed gears. This is on the near side, and a forward extension of the drive shaft carries a double pulley for the twin fan belts. On the timing cover, in line With the camshaft, with the end of which its extended, shaft engages, is the water pump. This auxiliary is mounted away from the cover to render the entry of water impossible.

' Fuel is lifted by an Autovac, and a Tecalemit filter is included in the line to this from the 35-gallon tank, whilst there is a C.A.V.-Bosch filter on the injection-pump side.