THE MAINTENANCE

Page 62

Page 63

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

and TUNING of AMAL

CARBURETTERS

BEFORE giving any detail of the working of the Amal carburetter a few general facts should be understood. First and foremost is cleanliness, and this point cannot be emphasized too much. It will well repay any vehicle owner to insist on only clean petrol being used.

Just as the petrol must be clean, so must the air which enters the carburetter, chiefly via the main intake. An air filter can be installed with great benefit.

Incidentally, Amalgamated Carburetters, Ltd., Holforcl Works, Perry Barr, Birmingham, realizing the importance of cleanliness, has put on the market a very efficient petrol filter which is easy to fit ; all collected foreign matter can be seen in a glass container, which is instantly detachable for cleaning purposes. The company's air filter consists of a felt bag of large area, so that there is a minimum of restriction at the air intake.

Preventing Air Leaks.

The next thing is to see that the joint between the engine and the car buretter is absolutely tight ; in this connection a washer of Hallite or similar material should be used.

-In time such parts as the throttle spindle and throttle valve are bound to become worn so that it is advisable to replace them before the performance of the engine makes this too obvious.

It should hardly be necessary to enlarge on the importance of keeping the engine in tune, particularly the ignition system, as this is very closely connected with the functioning of the carburetter. With very rate exceptions it will be found that the carburetter is set correctly for the engine before it leaves the works.

s36 Should any alteration be necessary owing to engine variation, the advantages of Amal simplicity and ease of tuning will become apparent.

We might here add a warning to see that all jets and nuts are properly tightened to prevent any possibility of leakage past the threads and to see that the full openings of the throttle valve and strangler are being obtained.

The Amal carburetter is made in two patterns—the pump type and that with the economizer device.

Dealing with the pump carburetter first, the following is a general description of the principles of this instrument. By virtue of special design of the choke, pilot system, bridging orifice and petrol passages the mixture strength is kept correct at any desired position of the throttle.

Automatic compensation, which means supplying the correct proportions of petrol and air for each point in the throttle range, is obtained by utilizing the natural principles of flow. The main jet contains, besides the petrol orifice, an air jet, which not only aids atomization, but chiefly serves another purpose, that of compensation. When the engine• speed increases under light loads, this air jet enables an increased amount of air to flow, owing to its density being lighter than that of petrol, automatically compensating the tendency for a greater petrol flow. A reverse state of affairs occurs under opposite conditions.

Uniform Mixture Essential.

As regards diffusion, it is a wellknown fact that unless the mixture of petrol and air delivered by the carburetter is in a thoroughly wellmixed condition to form a body of gas of uniform strength, the rate at which this gas will explode is seriously interfered with, thus causing loss of power and the use of a needless amount of petrol.

In the Amal a preliminary mixing of air and petrol takes place in the jet chamber, and this mixture then passes to the groove around the choke. Owing to the special design of the choke, the air passing through it has a high velocity, and as the petrol emulsion issues from the choke groove through the small diffuser tubes into this air stream it becomes very intimately mixed with the main hotly of air.

As the result of experiment in devising further means to cheek the increased cost of transport the Amal technical research department has evolved yet another idea. The device concerned ensures automatic weakening of mixture when throttling down, the gas automatically resuming normal strength when the throttle is again opened.

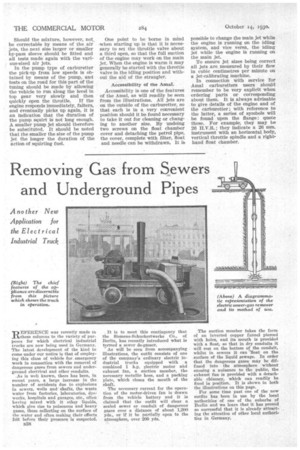

The economizer is illustrated on this page, and it will be seen that it consists of an air leak with a valve controlled automatically from the throttle spindle by means of a spring. When the• throttle lever begins to close the air-leak valve is opened, thereby weakening the mixture while the engine is not pulling. So soon as the throttle begins to open the air-leak valve is closed and the mixture resumes normal strength.

• The economizer device is integral with the casting of the carburetter body and is, therefore, not able to be supplied separately to fit oldertype Ama.ls.

An Aid to Acceleration.

In reference to the pump-type carburetter this gives better acceleration, because, whenever the accelerator is depressed violently the pump forces petrol into the choke, enriches the mixture and maintains the richness until the engine has gained the required speed. Once set, the pump is entirely automatically controlled from the throttle spindle. As the pump automatically enriches the mixture when quick acceleration is required, the carburetter can be set to give a weaker mixture for normal running than if the pump were not employed.

Owing to the pump, the engine does not depend entirely on its own suction to draw fuel from the carburetter jets; a larger carburetter choke therefore can be used, with the result that the power output is increased. No flooding is necessary, as on a cold morning petrol can be forced into the induction pipe by sharply depressing the accelerator two or three times.

Having described the construction of the carburetters, we will now explain the simple tuning, which covers idling, main-jet size and the bridging of idling and main -jets, in _the order in which they should be carried out. To set the carburetter for idling, close the throttle valve so that the engine runs on the idling jet. The quantity of the idling mixture is controlled by the idling jet and the quality by the slow-running adjustink screw.

Should the engine run too fast, the slow-running adjusting screw should be turned in a clOckwise d ection, and vice versa. If reasonably good idling cannot be obtained, even if the screw be turned to the fullest extent in either direction, it is an indication that the idling jet is not the correct size. When deciding whether a larger or smaller jet is required it should be noted from the trials with the slow-running adjusting screw whether the engine continues to run longer with the slowrunning adjusting screw turned inwards or outwards. If it runs for a longer time with the sereW turned fully in, it is an indication that the idling jet is too small, and the next larger size should be fitted and a further adjustment of the air-adjusting screw made until correct idling is obtained.

Too large a main jet as a general rule causes petrol consumption to be very heavy and the running of the engine to be woolly and irregular at medium and high speeds.

• If the main jet be too small .it will cause • loss of power ; a very obvious indication of • this is given by firing back through the carburetter when accelerating. The engine will also run very harshly and a little on the warm side, Where it .is found that the same speed is obtained with two jets of different sizes, the smaller of the

two should always be chosen on the score of economy.

Having obtained good idling and the correct main jet, adjustments can be made to obtain the correct bridging effect between these two by means of the by-pass system.

Absence of Flat Spots.

To test for this, the engine should be allowed to idle and the throttle opened slowly until the engine is running on the main jet. If there be found a point at which hesitation in coming from the idling to the main jet takes place, anti this hesitation is of a " hunting " or " lumpy " nature, it is an indication that the bridging mixture is too rich. On the other hand, if the hesitation be of an intermittent type, it is an indication that the bridging mixture is too weak.

The correction for rich mixture is to increase the size of by-pass air jet, but, if the mixture be weak, obviously a smaller by-pass air jet should be fitted. Should the mixture, however, not be correctable by means of the air Jets, the next size larger or smaller by-pass sleeve should be fitted and all tests made again with the various-sized air jets.

In the pump type of carburetter the pick-up from low speeds is obtained by means of the pump, and tests on the road for this part of the tuning should be made by allowing the vehicle to run along the level in top gear very slowly and then quickly open the throttle. If the engine responds immediately, falters, and eventually picks up again, it is an indication that the duration of the pump squirt is not long enough. A smaller pump jet should therefore be substituted. It should be noted that the smaller the size of the pump jet the longer the duration of the action of squirting fuel. One point to be borne in mind -when starting up is that it is necessary to set the throttle valve about a third open, so that the full suction of the engine may work on the main jet. When the engine is warm it may generally be started with the throttle valve in the idling position and without the aid of the strangler.

Accessibility of the Anial.

Accessibility is one of the features of the Atrial, as will readily be seen from the illustrations. All jets are on the outside of the carburetter, so that each is in a very convenient position should it be found necessary to take it out for cleaning or changing to another size. By undoing two screws on the float chamber cover and detaching the petrol pipe, the cover, complete with filter, float and needle can be withdrawn. It in

possible to change the main jet while the engine is running on the idling system, and vice versa, the idling jet while the engine is running on the main jet.

To ensure jet sizes being correct all jets are measured by their flow in cubic centimetres per minute on a jet-calibrating machine.

. In connection with service for Amal carburetters users should remember to be very explicit when ordering parts or corresponding about them. It is always advisable to give details of the engine and of the carburetter ; with reference to the latter, a series of symbols will be found upon the flange: quote these. For example, they may be 26 H.V.R.; they indicate a 26 mm. instrument with an horizontal body, vertical throttle spindle and a righthand float chamber.