ALL-WHEEL BRAKES AT THE PARIS SALON.

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Progress in Design as Shown by the Great Annual Continental Exhibition of Private Cars. New Types of Hydraulic and Vacuum-operated Brakes.

T T is now generally felt that, however satisfactory

may be the brakes on the majority of commercial inotor vehicles, the effect of the employment of allwheel brakes on private cars, and the desire to make assurance doubly sure, will bend the minds of designers, makers and users strongly in the direction of the use of front-wheel brakes,. the first result being their employment for certain types, such as the express delivery van running at high speeds, the touring motor coach operating in hilly districts and, perhaps, the taxicab ; indeed, there are several cabs already operating in Paris which carry the distinctive sign, " Attention : Freins avant," thus showing that they are equipped with the latest method of braking. In the pleasure car, of course, front-wheel brakes have become used to a remarkably great extent on chassis of all sizes, and it is, therefore, necessary to give heed to the example thus set whilst at the same time it is of considerable interest to note the progress in design revealed by such a representative exhibition as that held at the Paris Salon.

One of the striking features is that, whereas last year there were many cars fitted with brakes which left a great deal to be desired, and were even

C32

thoroughly unsafe in many instances, very few poor designs were noticeable this year. Apparently, whilst some manufacturers thought it necessary to adopt front-wheel brakes to bring their products up to date for the last Show, and had not had the opportunity to give much thought to the problem, their experiences during the past year have shown how essential it is to adopt a safe brake, and to redesign much of the forward part of the chassis in order to withstand the additional braking stresses.

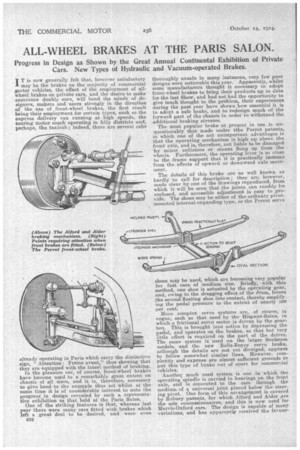

The most popular brake at present in use is unquestionably that made under tthe Perrot patents, in which one of the not unimportant advantages is that the operating mechanism is high up above the front axle, and is, therefore, not liable to be damaged by minor collisions or stones flung up from the wheels. Furthermore, the operating lever is so close to the frame support that it is practically immune from the effects of upward or downward axle moveinent.

The details of this brake are so well known as hardly to call for description ; they are, however, made clear by one of the drawings reproduced, from which it will be seen that the joints can readily be enclosed, and accessible adjustment is easy to provide. The shoes may be either of the ordinary pivotmounted internal-expanding type, or the Perrot servo

shoes may be used, which are becoming very popular for fast cars of medium size. Briefly, with this method, one shoe is actuated by the operating gear, and, owing to the dragging effect of the drum, forces the second floating shoe into contact, thereby amplifying the pedal pressure to the extent of nearly 300 per cent.

More complex servo systems are, of course, in vogue, such as that used by the Hispano-Suiza, in which a frictional servo motor is driven by the gearbox. This is brought into action by depressing the pedal, and operates on the brakes, so that but very little effort is required on the part of the driver. The same system is used on the larger Sunbeam models, and the new Rolls-Royce servo brake, although the details are not yet divulged, appears to follow somewhat similar lines. However, complexity and expense are almost sufficient grounds to put this type of brake out of court for commercial vehicles.

Another much used system is one in which the operating spindle is carried in bearings on the front axle, and is connected to the cam through the medium of a universal joint placed below the steering pivot. One form of this arrangement is covered by Rubury patents, for which Alford and Alder sire the sole coneessiormairee, and this is now used for Morris-Oxford cars. The design is capable Of many variations, and has apparent'y received the favour

able attention of French designers. In some cases the universal joint has been dispensed with, a spherical surfaced cam being mounted directly on the end of the operating spindle.

In yet another arrangem e n t, developed b y Hotchkiss, a lever at the end of a spindle carried on the axle operates a pull rod, which, in turn, is attached to a lever secured to the cam. A somewhat similar system has been adopted by Rolls-Boyce, and, although effective, it would appear to be liable to accidental damage, and, .therefore, not entirely suitable for commercial vehicles.

Continuing to classify broadly, we come to the systems which utilize an operating rod passing down the centre of the steering pivot and actuating the shoes either by a wedge or a toggle mechanism. Arrangements of this kind have been adopted by Vauxhall, and also in the brakes recently fitted to Austin cars. Incidentally, somewhat similar principles are used in the brake applied to the Flint (a popular American car), the design of which seems particularly well suited for commercial vehicles.

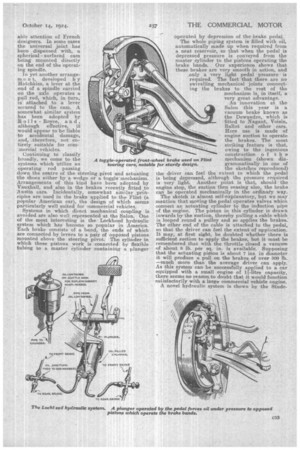

Systems in which direct mechanical coupling is avoided are also well represented at the Salon. One of the most interesting is the Lockheed hydraulic system which has become so popular in America. Each brake consists of a band: the ends of which are connected by levers to a pair of opposed pistons mounted above the steering pivot. The cylinder in which these pistons work is connected by flexible tubing to a master cylinder containing a plunger

operated by depression of the-brake pedal.

The whole piping system is filled with oil, automatically made up when required from a neat reservoir, so that when the pedal is depressed pressure is conveyed, from the master cylinder to the pistons operating the brake hands. Our experience shows that these brakes are very smooth in action, and .only a very light pedal pressure is required. The fact that there are no swivelling mechanical joints connecting the brakes to the rest of the mechaniam is, in itself, a very great advantage.

An innovation at the Salon this year is a vacuum brake known as the .newandre, which is fitted to Nagant, Ballot and other cars. Here use is made of engine suction to operate the brakes. The most striking feature is that, owing to the ingenious construction of the mechanism (shown diagrammatically in one of the sketches reproduced) the driver can feel the extent to which the pedal is being depressed, although• the pressure required is very light. Another point is that, should the engine stop, the suction then ceasing also, the brake can be operated mechanically in the ordinary way. The sketch is almost self-explanatory, but we may mention that moving the pedal operates valves which connect an actuating cylinder to the induction pipe of the engine. The piston in this cylinder is drawn inwards by the suction, thereby pulling a cable which is looped round a pulley and so applies the brakes. The other end of the cable is attached to the pedal, so that the driver can feel the extent of application. It may, at first sight, be doubted whether there is sufficient suction to apply the brakes, but it must be remembered that with the throttle closed a vacuum of about 8 lb. per sq. in. is available. Supposing that the actuating piston is about 7 ins, in diameter it will produce a pull on the brakes of over 300 lb. —much more than the average driver can apply. As this system can be successfully applied to a car equipped with a small engine of capacity, there seems no reason to doubt that it would function satisfactorily with a large commercial vehicle engine. A novel hydraulic system is Flown by the Stude

baker concern in which there is a pump mounted behind the gearbox. This circulates oil continuously. but when the pedal is depressed, a valve is closed which forces the oil to pass into a cylinder containing a pair of pistons. These pistons are pushed outwards, operating the brakes through a mechanical gear. Matters are so arranged that independent manual operation is possible should the hydraulic system fail for any reason.

The Continental designer appears tt have taken considerable pains to ensure that there shall be adequate strength' to resist braking stresses. Thus, in going round. the Salon, one notiees that on all' ears equipped with front-wheel brakes the springs are particularly broad and strong, and are practically flat when loaded. A flat spring, of course, is better able to convey the retarding effect from the axle to the frame than one which is heavily cambered. Then, . again, the axle ends are usually of circular or oval section, the better to resist twisting, and the spring shackles are particularly robust. Tie-rods are used between the front dumb-irons to stiffen the frame.

To slim up, the impression gained is that front

wheel. brakes have now passed far beyond the experimental stage, and are destined to become as universally adopted as electric lighting on pleasure cars. It will be interesting to see to what extent this feature will, in the future, gain headway in the commercial vehicle field