When a body meets a body — Trevor longcroft in Kelvin Hall

Page 56

Page 57

Page 58

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

Aluminium offers a brighter outlook

TO GIVE Scottish operators increased vehicle efficiency, bodybuilders are turning to aluminium construction in order to provide more payload capacity and less maintenance, to judge from exhibits I examined last •week in Glasgow.

At the Scottish Motor Show —closing tomorrow—the use of aluminium is restricted, in the heavier vehicle classes, to flat-platform body sub-frames with timber floors still the standard. But as unladen weight becomes a more critical factor—in avoiding either hgv licence or plating regulations—the aluminium content is stepped up.

Using aluminium rather than steel for the sub-frame on the 6.1m (20ft) flat-platform body on the Fiat 130 NC 13-tonne rigid has enabled C. M. T. Munro Ltd of Rutherglen to shave around 152kg (3cwt) off bare body weight. Unladen weight of the complete vehicle is 4.6 tonnes (4.5 tons), giving a total payload capacity of 8.6 tonnes (8.5 tons) at 13 tonnes (12.8 tons) gvw.

The new Scania LB81 5.4m (17.7ft) wheelbase rigid at Kelvin Hall is also shown with a composite construction body, built by Fleming and Taylor of Airdrie. The flat-platform body stops just short of the chassis rear in order to make way for a vehicle-mounted HIAB lorry loader.

Basically there is little to choose in weight between an aluminium or timber floor. The former is more expensive, but does not warp and does provide a good hygienic surface that is easy to wash down.

Payload changes

Only one 16-ton haulage model featuring an all-aluminium body is at Kelvin Hall. Built by Fleming and Taylor, it is a fine example of Scottish workmanship. Unladen weight of the 16-tonner with the aluminium body is 4.7 tonnes (4.6 tons) giving a legal payload of 11.5 tonnes (11.4 tons). The body costs £760, and with a timber floor cost would drop to just below £700.

On January 1, 1976, the UK is due to adopt the EEC 7.5tonne (7.4-ton)-gvw limit for hgv licence requirement. Operators already running vehicles based on the existing 3-ton unladen limit will be anxiously wondering by how much the change will affect payload capacities.

Again, composite construction bodies with aluminium sub-frames seem to be the standard, with all vehicles plated to 7.5 tonnes (7.4 tons) gvw having unlad.e.n weights of less than 3 tons. If these vehicles are purchased before January 1 no down-plating will be necessary to meet the new regulations.

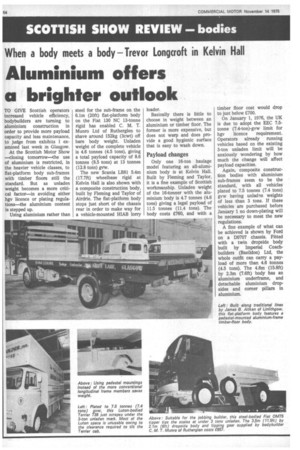

A fine example of what can be achieved is shown by Ford on a D0707 chassis. Fitted with a twin dropside body built by Imperial Coachbuilders (Basildon) Ltd, the whole outfit can carry a payload of more than 4.6 tonnes (4.5 tons). The 4.8m (15.8ft) by 2.3m (7.6ft) body has an aluminium underframe, and detachable aluminium dropsides and corner pillars in aluminium. Still under 3 tons unladen but plated to 7.6 tonnes (7.5 tons) gvw, is a Terrier 750 chassis fitted with a traditional fiat-platform body built by James B. Aitken of Linlithgow. To reduce body weight the bodybuilder has done away with the longitudinal body main-frame members and used pedestal mountings between vehicle chassis and body crossmembers. A spring change will enable the Terrier to be downplated to comply with the new hgv weight limit, but until then the operator has the benefit of a further 121kg (2.4cwt) payload.

Luton head bodies can also be built to get vehicles within the 3-ton-unladen limit and one mounted on a Terrier 738 chassis is shown by Taggarts (Motherwell) Ltd. Although it is built to customer specification, it is difficult to understand the logic of the Luton head. To provide adequate body clearance to tip the cab for repairs and maintenance, only half of the Luton capacity is usable, the floor being inset high into the head.

In the under-30cwt-unladen market, competition among bodybuilders has always been fierce. The introduction of the new VW LT light truck range into the UK has resulted in a fresh injection of bodybuilder enthusiasm.

The general feeling among bodybuilders is that the VW LT31 chassis-cab is marginally too heavy when compared against the competition.

However, VW has noted the criticism and is to change the tyre specification and also trim unnecessary metal from the chassis and so reduce weight.

Design intelligence

Bodies fitted to the VW and other chassis-cabs at the Show are a far cry from the flimsy designs that were around not so many years ago. Obviously, vehicle manufacturers' body approval schemes and healthy competition have sorted out the shoddy builders.

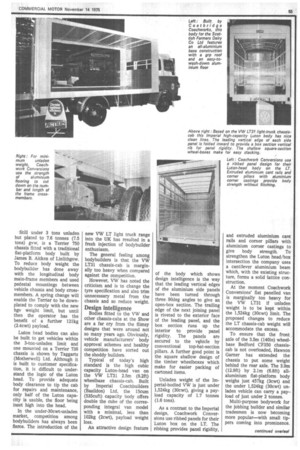

Typical of today's high standard is the high cubic capacity Luton-head van on the VW LT31 2.5m (8.2ft) wheelbase chassis-cab. Built by Imperial Coachbuilders (Basildon) Ltd, the 15cum (535cuft) capacity body offers double the cube of the corresponding integral van model with a minimal, less than 102kg (2cwt), payload weight loss.

An attractive design feature of the body which shows design intelligence is the way that the leading vertical edges of the aluminium side panels have been turned through three. 90deg anglesto give an open-box section. The trailing edge of the next joining panel is riveted to the exterior face of the leading panel, and the box section runs up the interior to provide panel rigidity. The panels are secured to the vehicle by conventional top-hat-section pillars. A further good point is the square shallow design of the timber wheelboxes which make for easier packing of cartoned items.

Unladen weight of the Imperial-bodied VW is just under 1,524kg (30cwt), giving a payload capacity of 1.7 tonnes (1.6 tons).

As a contrast to the Imperial design, Coachwork Conversions use ribbed panels for their Luton box on the LT. The ribbing provides panel rigidity, and extruded aluminium cant rails and corner pillars with aluminium corner castings to give body strength. To strengthen the Luton head/box intersection the 'company uses a cantilever aluminium beam which, with the existing structure, forms a solid 'lattice construction.

At the moment Coachwork Conversions' flat panelled van is marginally too heavy for the VW LT31 if unladen weight is to be kept within the 1,524kg (30cwt) limit. The proposed changes to reduce the LT chassis-cab weight will accommodate the excess.

To ensure that the front axle of the 3.5m (140in) wheelbase Bedford CF350 chassiscab is not overloaded, Hawson Garner has extended the chassis to put some weight behind the rear axle. The 3.9m (12.9ft) by 2.1m (6.8ft) allaluminium flat-platform body weighs just 457kg (3cwt) and the under 1,524kg (30cwt) unladen vehicle can carry a pay-, load of just under 2 tonnes.

Multi-purpose bodywork for the jobbing builder and similar tradesmen is now becoming more popular—with small tippers coming into prominence.

All aluminium

To offset the weight of underbody tipping gear Anthony Carrimore has an allaluminium dropside tipper body. When mounted on a Leyland Sherpa 250 chassis-cab with diesel engine, the outfit just falls within the 30cwt limit to give a payload of 1,118kg (22cwt). The 2.6m (8.5ft) by 1.8m (6ft) body has removable dropsides and corner pillars for flat platform operation. The poor body finish leaves the observer in no doubt that it had been a rush job for Kelvin Hall.

The Perkins Tipmaster body on the VW LT31 chassis-cab features an all-steel body with dropsides. The single front ram is electric/hydraulic powered by a pack in the vehicle cab. Unladen vehicle weight is again below 1,524kg (30cwt), giving the vehicle a payload of 1,524kg (30cwt).

In comparison to recent British shows the demountable body takes a back seat at Kelvin Hall. However, A. C. Penman of Dumfries does show a prototype demountable system which will eventually be able to demount ISO containers and demountable bodies fitted with twistlocks.

The prototype system utilises existing equipment, but in place of the current body/ chassis lock the body is secured on to the chassis by a conventional twistlock. This seems the closest yet that anyone has come to devising a universal clear-lift demountable system and if manufacturers could be persuaded to fit ISO corner castings on demount bodies then many operators' headaches could well be solved. Using ISO twistlocks, says the company, makes it easier for customers to get spares in the unlikely event of a break.

In anticipation of Britain becoming a signatory to the European Agreement on Carriage of Perishable Foodstuffs (ATP), A. C. Penman has started to import Danish-built Frigor refrigerated bodies in CKD form for assembly and marketing in the UK. France and Germany are already signatories to the agreement, which lays down certain body standards for carrying perishable foodstuffs.

The refrigerated containers are designed for use with skeletal chassis or semi-trailers and their grp-faced polyure thane-foam-sandwich singlepanel construction is claimed to offer higher payloads and greater thermal efficiencies than other similarly constructed units. On a 12.2m (40ft) box with skeletal trailer basis, the Frigor outfit is claimed to be up to 1 tonne lighter than conventional outfits and up to 508kg (10cwt) lighter than chassisless designs. The panel heat-loss coefficient is less than that stipulated in the ATP agreement and body thermal efficiency is guaranteed for six years.

A hybrid

In the TIR trailer field Taskers have designed a hybrid semi-chassisless semitrailer. One side features an all-welded-steel van-type construction, the other a =yen tional TIR tilt superstructure; the roof is made either from grp or from aluminium.

The design offers a 2.5m (8.3ft) floor to roof height within the European 4m overall height limit, and the semitrailer is designed to operate at up to 38 tonnes gcw. Unladen weight is 6 tonnes.

A 'cm tilt superstructure from Collen (Transport Designs) Ltd featuring an extendable roof is shown by Northern Vehicle Distributors. The tilt roof can be raised from 3.6m (11.8ft) to 4m (13.1ft) overall height, and is designed to let operators take full advantage of any changes to the maximum overall vehicle height permitted on the German railway Piggyback system. I understand that German authorities are investigating the possibilty of lifting the maximum vehicle heights for the Piggyback system from the present 3.6m (11.8ft) limit to at least 3.85m (12.6ft).