• Leyland must rationalise

Page 77

Page 78

If you've noticed an error in this article please click here to report it so we can fix it.

Bob Beresford, Truck and Bus Division chief engineer (vehicle engineering), talks to Graham Montgomerie of the enthusiasm current at BL and says model duplication will be reduced without alienating the 'traditionalist' opinions of most operators

G. S. Montgomerie: The problems of Leyland have been too well documented to go into again, but what has been the effect of the Ryder report?

T. R. Beresford: There is a lot of enthusiasm around that was not there before. It's all so different to the situation of just two years ago. In effect you can say that that was one of the biggest effects of Ryder—it was a great morale booster. Our future new model ranges should reflect this—without being too specific!

One of our biggest problems is how to balance our resources and I'm thinking here in terms of people. We have recruited very well in the chassis area, but we're still looking on the transmission side. We have done a lot of advertising for the right people—not entirely successfully.

The Ryder report will definitely help us in that we have now got the money for new test facilities. We have started now in a small way, but you must remember that the facility here is really a Leyland Motors facility which is being used for the whole group and this can cause major problems. We do utilise outside testing facilities such as NEL at East Kilbride, but you have to recognise that you get a better feedback of information if it's your own testing. When it's done at home everybody is near enough to go and look at what's happening—and this is most important.

GSM: In which market areas do you think the Leyland vehicles are at their most competitive? TRB: The Octopus as our newest model has got to be more than competitive in its weight category. The twospring bogie has helped a lot to keep the weight down and operators who have had experience of it already, on the Bison, for example, have a favourable opinion. This weight saving is obviously very useful to the operator. The design of the bogie can and will be developed to answer some of the criticisms received on accessibility.

The Buffalo has proved to be the right vehicle for a lot of operators and there is nothing much wrong with the Reiver, which holds a big slice of its market. The Super Mastiff is very well thought of and this vehicle at the moment gives us the least warranty problems. The Boxer range? Again nothing wrong with this, but I have to admit that the Terrier has been disappointing. We just haven't got the share of the market we had hoped for. The Super Hippo, of course, goes on for ever. This hasn't been altered very much at all —there hasn't been a need to. But there is a lot of hand-building in it, which means it's not all that economic.

Turning to the bus side, we've got to stand out well in front, certainly on doubledeckers. The first B15 is now with London Transport for driver training—then we shall see! I think that even the humble public will agree that something has improved here. GSM: Could you comment on some of the recent criticism of the B15's kerb weight?

TRB: We have got to get a bit of weight out and all areas can play their part in this, be they chassis or body. Prototypes very often weigh heavy due to modified bracketry and so on, so the fifth model to be built (the others were really all prototypes) is being monitored very carefully during build for weight as this will be representative of a job-one production model.

GSM: Many operators were disappointed when it was announced that production of Guys would cease because it meant that they could not buy a Leyland truck with a Gardner engine.

TRB: Well, in fact, Guy did not fit many Gardner engines anyway. Here you can get drawn into the situation of having a very fine balance. On the one hand you take into account what the public wants, but on the other hand you cannot afford to pander to a customer's every requirement or you end up with a ridiculous number of model variants. The old days when the engineer felt the product was right and then gave it to the sales department to sell are long gone—it's now much more of a combined effort on customer requirements and specification.

GSM: How is Leyland managing in the light of the current succession of vehicle legislation requirements?

TRB: Well, for example, we have this terrible situation in the EEC in terms of braking regulations. We have to put in a lot c effort to maintain business in Europe, especially Belgium, France and Holland—but they keep changing the dates and the standards. It's difficult to try when they keep moving the goal posts. As,for Australia —they just went off into the night on legislative moves. The vertical exhaust requirement, for example, has been ignored by most.

GSM: Do you feel that buying major components from outside, particularly in the drive line, means you have to make a big design compromise in the area of matching compared with designing and manufacturing to suit your own particular vehicles?

TRB: In the engineering set-up at Leyland we have one section responsible for the power train and they are very aware of the problems associated with train matching. The 'use of whose gearbox we use will have to be looked at in the light of National Enterprise Board economics. There is a very fine line between manufacturing yourself and buying the bits outside. Before you decide to produce a gearbox yourself, you have to decide what equipment you have now and what • machine tools you will have to replace and so on. It can get costly. On the other hand you can go too far and become just a vehicle assembly company. We don't just sell trucks— we sell capital equipment and so we must balance the volumes we want and the price we want.

GSM: There is a fair degree of model duplication in the Leyland range at the moment and now the Octopus has added another eight-wheeler. What are the future plans in the area of rationalisation? TRB: There is going to be rationalisation right across the model range eventually. You mentioned eight-wheelers. Here the Routeman is very well accepted but it suffers because it is an expensive cab to produce. It's very labour intensive and that's not good business. We must rationalise—there is no doubt about that.

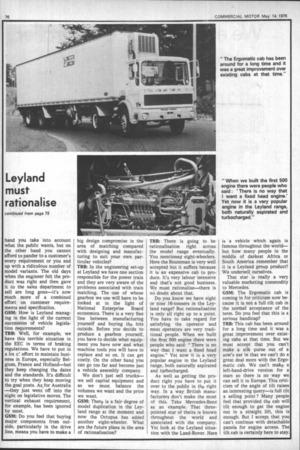

Do you know we have eight or nine 16-tonners irk the Leyland range? But rationalisation is only all right up to a point. You have to take regard for satisfying the operator and most operators are very traditional people. When we built the first 500 engine there were people who said: "There is no way that I want a fixed head engine." Yet now it is a very popular engine in the Leyland range, both naturally aspirated and turbocharged.

As well as getting the product right you have to put it over to the public in the right way. In a way British manufacturers don't make the most of this, Take Mercedes-Benz as an example. That threepointed star of theirs is known throughout the world and associated with the company. Yet look at the Leyland situation with the Land-Rover. Here is a vehicle which again is famous throughout the world— but how many people in the middle of darkest Africa or South America remember that it is a Leyland group product? We undersell, ourselves. That star is really a very valuable marketing commodity to Mercedes.

GSM: The Ergomatic cab is coming in for criticism now because it is not a full tilt cab in the normal acceptance of the term. Do you feel that this is a serious handicap?

TRB: This cab has been around for a long time and it was a great improvement over existing cabs at that time. But we must accept that you can't make a silk purse out of a sow's ear in that we can't do a great deal more with the Ergomate cab. We can't make a left-hand-drive version for a start so there is no way we can sell it in Europe. This criticism of the angle of tilt raises an interesting query—is full tilt a selling point ? Many people feel that provided the cab will tilt enough to get the engine out in a straight lift, this is enough. But I accept that you can't continue with detachable panels for engine access. The tilt cab is certainly here to stay.