ANEW FLAT TWIN OIL ENGINE

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

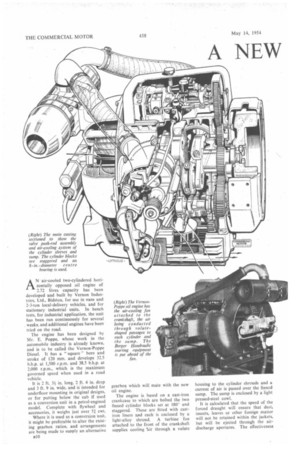

AN air-cooled two-cylindered horizontally opposed oil engine of 2.72 litres eapacity has been developed and built by Vernon Industries, Ltd., Bidston, for use in vans and 2-3-ton local-delivery vehicles, and for stationary industrial units. in bench tests, for industrial application, the unit has been run continuously for several weeks, and additional engines have been tried on the road.

The engine has been designed by Mr. E. Poppe, whose work in the automobile industry is already known, and is to be called the Vernon-Poppe Diesel. It has a " square " bore and stroke of 120 mm. and develops 32.5 b.h.p. at 1,500 r.p.m. and 38.5 b.h.p. at 2,000 r.p.m., which is the maximum governed speed when used in a road vehicle.

It is 2 ft. 31 in. long, 2 ft. 4 in. deep and 3 ft. 9 in. wide, and is intended for underfloor mounting in original designs, or for putting below the cab if used as a conversion unit in a petrol-engined model. Complete with flywheel and accessories, it weighs just over 51 cwt.

Where it is used as a conversion unit, it might be preferable to alter the existing gearbox ratios, and arrangements are being made to supply an alternative BIO gearbox which will mate with the new oil engine.

The engine is based on a cast-iron crankcase to which are bolted the two finned cylinder blocks set at 180° and staggered. These are fitted with castiron liners a.ad each is enclosed by a light-alloy shroud. A turbine fan attached to the front of the crankshaft

supplies cooling through a volute

housing to the cylinder shrouds and a current of air is passed over the finned sump. The sump is enclosed by a light pressed-steel cowl.

It is calculated that the speed of the forced draught will ensure that dust, insects, leaves or other foreign matter will not be retained within the jackets, but will be ejected through the airdischarge apertures. The effectiveness of the cooling system has been demonstrated during the prolonged bench tests made with artificially high surrounding temperatures.

The Vernon-Poppe engine has direct injection and a compression ratio of 1:i to I, the injectors being set out of vertical to the cylinder bores and spraying into toroidal-shaped chambers formed in the pistons, Hepolite aluminium-alloy pistons are used, the top compression ring being chromiumplated. There are three compression and two oil-control rings to each piston, The connecting rods are conventional stampings split obliquely at the big-ends for withdrawal through the cylinder bores.

Features of the three-bearing crankshaft include dovetail-fitted counterbalance weights and an 8-in, diameter intermediate main bearing. Lead-bronze indium-coated bearings are used at the connecting-rod big-ends, but the main bearings are lined with white-metal, The front and centre bearings are complete bushes, but the rear bearing is split and flanged to control end float.

Spur gears at the flywheel end of the crankshaft provide the drive for the fuel-injection-equipment camshaft and the main camshaft, the latter being housed in the main casting and operating the valves through push-rods and lockers. An unusual detail is the replacement of conventional tappet blocks by half rockers pivoted to the main casting and bearing direct on the cam lobe.

ACONVERSION to forward control of a Commer Superpoise 5-ton lorry of H. E. Ormerod Ltd., Derby Garage, Manchester Road, .Bury, has been carried out by an associate company, P. and E. Finney, Ltd. The lorry has a platform body measuring 17 ft. 6 in. by 7 ft. 6 in. on the standard 13-ft. 11-in.-wheelbase chassis, this representing an increase in length of 2 ft.

The conversion, which has been carried out with the full approval of The opposite face of the half rocker is shaped to support the pencil end of the push-rod. Dual valve springs are used.

The two cylinder heads are made of Y alloy, each being secured to the barrel by five studs. Valve-seat inserts of cast iron are fitted, the port diameters being It in. inlet and exhaust. The push-rods and rocker gear are enclosed, the head assembly being covered by a shallow light-alloy inspection plate.

Air for combustion is drawn through a Vokes filter, which is located in front of the cooling-fan intake and is ported through a Y-shaped induction pipe to the two heads. Provision is made in the induction pipe for a C.A.V. ether starting device for extreme cold starting in the cooler climates. The engine can be fitted with manual, electric or Berger Handraulic starting equipment, that shown on the drawing being of the lastnamed type.

The sump capacity is 2.1gallons and the gear-type pump, working at 40 p.s.i., is driven from the camshaft. Oil is supplied direct to the crankshaft bearings and the connecting rods are drilled for lubrication to the gudgeon-pin bushes. A Yokes by-pass filter is incorporated.

Easy access to all parts is one of the aims of the design, For instance, the two C.A.V. single-element-plunger fuel injection pumps are mounted on a plate at the top of the main casting and when this plate is removed, the connectingrod big-end bearings and other working components can be reached, The combined oil filler and breather has a built-in non-return valve which maintains a slight depression in the crankcase to prevent oil leaks.

Although the cost of the VernonPoppe engine is not yet known, it is likely to he under £300.