Combining Lightness and Strength in Goods Bodies

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

AN important feature in almost any type of body is its transverse strength and rigidity. With a wide body, the cross-bearers, which considerably overhang each side of the chassis, should have sufficient strength to support the body and its load no matter how it may be distributed.

It is Practically impossible to make a body rigid lengthwise, a difficulty which increases with its length. Therefore, with a good foundation of cross-bearers, the designer should strive to give rigidity to the crosswise units of the framework.

Framework Features.

Such a unit may consist of a crossbearer with a side pillar secured at each end of it, with the tops of the pillars joined by a hoopstick. If these parts of the framework be in line, it simplifies the reinforcement of the joints of the cross-bearers with the pillars, also the joints of the pillars with the roof framework. At the same time, such reinforcement may be effected without adding any undue weight.

A front bulkhead which has no opening, except above it to give access to a Luton-type front, provides an opportunity of bracing the structure of the body. Diagonal struts are fitted below the front waist rail, between the outer and inner pillars on each side, with a small gusset plate to reinforce the joints. Above the waist there is a diagonal stay secured at each end to lugs.

The upper pair of lugs is welded to a flat plate screwed under the front top rail. There is no corresponding connection at the foot of the pillars, because here the cross-bearers are 1340 clipped d'rectly to the chassis, so that no additional reinforcement should be necessary.

At the back of the body there is not the same scope for ensuring rigidity. The rear corner pillars should be made wide enough to accommodate a strong back plate. If a full-width opening be not required, wide back pillars may be adopted, or an inner pair of pillars added and the space covered by a panel.

Enclosing the Rear.

A tailboard, when closed, helps to tie the two sides of the body together, but, when building to a weight limit, the size of the tailboard must be considered and a low one may be advisable. The provision of a pair of waterproof curtains is a weight-saving method of enclosing the upper_ part of the body. If curtains be not suitable, a pair of light doors, which may be covered with fabric, plywood or expanded metal, is substituted.

Cross-bracing of a long body between the front and rear can be done to only a limited extent. If the full headroom be not required at the sides, alternate hoopsticks may be fitted with gusset plates, but this part of the body may be strengthened, without obstruction, by corner plates screwed to the end of the hoopstick and the top of the cant-rail.

When there is a large squared-up wheel-arch, the ends of this enclosure may be extended below the floor, so that they may be secured to the cross-bearers, or even below this level if the side pillars be arranged with the ends of the wheel enclosure bearing on the pillars. These wheel-arch ends have a fillet for supporting the floorboards.

As a temporary means for crossbracing the body between the front

and back, removable tie-bars may be provided. Thesehave hooked ends similar to the spreaders which are fitted between, the side loading racks of a market-gardener's lorry. Alternative positions may be afforded for these tie-bars, so that they may be adjusted according to the exigencies of the load.

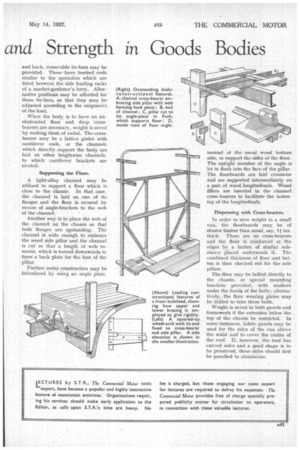

When the body is to have an un obstructed floor and deep 'crossbearers are necessary, weight is saved by making them of metal. The cross bearer may be a lattice girder with cantilever ends, or the channels which directly support the body are laid on other lengthwise channels, to which cantilever brackets are riveted.

Supporting the Floor.

A light-alloy channel may be utilized to support a floor which is close to the chassis. In that case, the channel is laid on one of its flanges and the floor is secured by means of angle-brackets to the web of the channel.

Another way is to place the web of the channel on the chassis so that both flanges are upstanding. The channel is wide enough to embrace the wood side pillar and the channel is cut so that a length of web remains, which is turned downwards to form a baek plate for the foot of the pillar.

Further metal construction may be introduced by using an angle plate, instead of the usual wood bottom side, to support the sides of the floor. The upright member of the angle is let in flush into the face of the pillar. The floorboards are laid crosswise and are supported intermediately on a pair of wood longitudinals. Wood fillers are inserted in the channel cross bearers to facilitate the fastening of the longitudinals.

Dispensing with Cross-bearers.

In order to save weight in a small van, the floorboards may be of stouter timber than usual, say, 11 ins. thick. There are no cross-bearers and the floor is reinforced at the edges by a batten of similar substance placed underneath it. The combined thickness of floor and batten is then checked out for the side pillars.

The floor may be bolted directly to the chassis, or special mounting brackets provided, with washers under the heads of the bolts ; alternatively, the floor wearing plates may be drilled to take these bolts.

Weight is saved in both panels and framework if the extension below the top of the chassis be restricted. In some instances, fabric panels may be used for the sides of the van above the waist and to cover the centre of the roof. If, however, the roof has curved sides and a good shape is to be preserved, these sides should first be panelled in aluminium.