Detroit chips in with an overhead camshaft six

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

• Over the past decade Detroit Diesel Allison — General Motors' diesel engine and automatic transmission-manufacturing subsidiary — has seen its share of the North American Class Eight (top weight on-road truck category) engine market dwindle away almost to nothing. Of the 130,000 or so Class Eight vehicles which were sold in North America last year, only 5% had Detroit Diesel engines. Once DDA would have been disappointed if its market share had dropped below 30%.

DDA's vee-eight and vee-six twostroke engines never found favour with European operators, mainly because of their poor fuel consumption. Now they have suffered a dramatic decline in popularity among American operators too, primarily because of reliability problems associated with water leaking into the lubricating oil.

GM has now restructured its diesel engine division, merging it with the diesel engine business of agricultural equipment manufacturer John Deere to form a 50/50 joint venture company which is to be called Dedec (Detroit Deere Corporation). It has also introduced an all new truck engine which has taken seven years to develop and is designed to leapfrog its competitors, chiefly Cummins and Caterpillar, in technical innovation, performance and market share.

Donovan Downham, Dedec's vicepresident of sales and marketing, is confident that the new engine, designated Series 60, will capture "at least 22% of the US heavy duty diesel market in the next five years."

Dedec's plans for selling the Series 60 engine in Europe are less clear, but there is no doubt that it will become available here. Floor, the Dutch specialist vehicle builder, has one of two Series 60 prototypes which have been shipped to Europe.

Foremost among the other European vehicle manufacturers who are at least potential customers for the Series 60 engines are ERF, Foden, Seddon Atkinson, Kassbohrer and Perlini, the Italian manufacturer of on/off-road trucks. Another surprising name on the list of possible customers for the new engine is Dal (and Leyland Oaf).

The Dutch manufacturer needs an engine to take it into the 300kW-plus onroad truck sector which is becoming in

creasingly important in Europe, and its own 11.6 litre engine, with a maximum power rating of 270kW (360hp) would probably be unduly stretched at much higher ratings. The Series 60 engine could provide Daf with a more costeffective option than a new engine development programme.

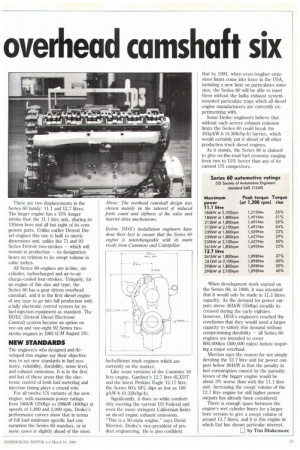

In the USA truck manufacturers who are already fitting Series 60 engines in their Class Eight models include Freightliner (owned by Daimler-Benz), Kenworth and Peterbilt (part of Paccar) and Volvo White, in addition to GM's own truck-building division, GMC. There are two displacements in the Series 60 family: 11.1 and 12.7 litres. The larger engine has a 15% longer stroke than the 11.1 litre unit, sharing its 130mm bore and all but eight of its component parts. Unlike earlier Detroit Diesel engines this one is built to metric dimensions and, unlike the 71 and 92 Series Detroit two-strokes — which will remain in production — its designation bears no relation to its swept volume in cubic inches.

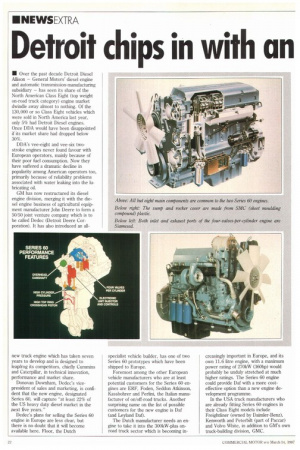

All Series 60 engines are in-line, six cylinder, turbocharged and air-to-air charge-cooled four-strokes. Uniquely, for an engine of this size and type, the Series 60 has a gear driven overhead camshaft, and it is the first diesel engine of any type to go into full production with a fully electronic control system for its fuel injection equipment as standard. The DDEC (Detroit Diesel Electronic Control) system became an option on vee-six and vee-eight 92 Series twostroke engines in 1985 (CM August 24).

NEW STANDARDS

The engineers who designed and developed this engine say their objective was to set new standards in fuel economy, reliability, durability, noise level, and exhaust emissions. It is in the first and last of these areas that the electronic control of both fuel metering and injection timing plays a crucial role.

For all twelve US variants of the new engine, with maximum power ratings from 186kW (250hp) to 298kW (400hp) at speeds of 1,800 and 2,000 rpm, Dedec's performance curves show that in terms of full load minimum specific fuel consumption the Series 60 matches, or in some cases is slightly ahead of the most fuel-efficient truck engines which are currently on the market, Like some versions of the Cummins 10 litre engine, Gardner's 12.7 litre 6LXDT and the latest Perkins Eagle 12.17 litre, the Series 60's SFC dips as low as 189 g/kW-h (0.311b/hp-h).

Significantly, it does so while comfortably meeting the current US Federal and even the more stringent Californian limits on diesel engine exhaust emissions. "This is a 50-state engine," says David Merrion, Dedec's vice-president of product engineering. He is also confident that by 1991, when even tougher emissions limits come into force in the USA, including a new limit on particulates emission, the Series 60 will be able to meet them without the bulky exhaust systemmounted particulate traps which all diesel engine manufacturers are currently experimenting with.

Some Dedec engineers believe that without such severe exhaust emission limits the Series 60 could break the 183g/1W-h (0.30Ib/hp-h) barrier, which would certainly put it ahead of all other production truck diesel engines.

As it stands, the Series 60 is claimed to give on-the-road fuel economy ranging from two to 15% better than any of its current US competitors.

When development work started on the Series 60, in 1980, it was intended that it would only be made in 11.1 Litres capacity. As the demand for power outputs above 261kW (550hp) steadily increased during the early eighties, however, DDA's engineers reached the conclusion that they would need a larger capacity to satisfy this demand without compromising durability — all Series 60 engines are intended to cover 800,000km (500,000 miles) before requiring a major overhaul.

Merrion says the reason for not simply derating the 12.7 litre unit for power outputs below 261kW is that the penalty in fuel consumption caused by the parasitic losses of the bigger engine would be about 3% worse than with the 11.1 litre unit. Increasing the swept volume of the 12.7 litre engine for still higher power outputs has already been considered.

There is enough space between the engine's wet cylinder liners for a larger bore version to give a swept volume of around 13.7 litres, and it is this engine in which Daf has shown particular interest.