Dennis Bulkmaster 70

Page 34

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

refuse collector

by Trevor Longcroft, pictures by Dick Ross Road test and operational trial 10/74

WHEN the Hestair Group acquired Dennis Motor Holdings in 1972 the company stopped making goods vehicles and turned its attentions wholly to the municipal market.

The company now offers, a wider range of municipal vehicles on a standard chassis having only wheelbase and tyre options. The standard specification includes the Perkins 6.354 engine, a 356mm (14in) single-plateclutch, five-speed EYT constant-mesh gearbox and Eaton single-speed rear axle.

The Bulkmaster 70 we have just tested was introduced in 1971 and is the largest sweeping-plate lifting-hopper refuse collection vehicle with intermittent loading that Dennis produces.

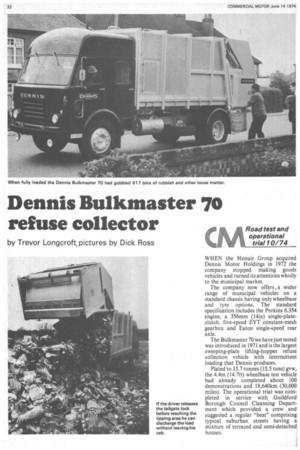

Plated to 15.7 tonnes (15.5 tons) gvw, the 4.4m (14.7ft) wheelbase test vehicle had already completed about 100 demonstrations and 18,640km (30,000 miles). The operational trial was completed in service with Guildford Borough Council Cleansing Department which provided a crew and suggested a regular "beat" comprising typical suburban streets having a mixture of terraced and semi-detached houses. One advantage claimed for intermittent loaders is that their overall performance is quieter than continuous-loading machines and this certainly seemed the case with our vehicle. More noise was made emptying the bins into the hopper and dropping them onto the ground than was made by the vehicle.

The hopper needed emptying at approximately 10-15 minute intervals. The mechanics of the device were noticeably quiet in operation and there was no body clatter. The most obtrusive sound was emitted from the increased engine revs required to drive the pto and this was acceptable even at 8.00 am.

When idling or crawling along the kerb the air compressor could be clearly heard above the engine's quiet idling note. Before the test the five-man crew had not worked with an intermittent loader and while they were quick to praise the low 1.1m (3.4ft) loading height and the low noise level it took a few minutes before they could make full use of it.

A small control panel close to the hopper houses the switch gear; until the body reaches a nearly full condition they need only to push one button for a fully synchronized action of the compaction mechanism; beyond this point the crew has to resort to separate controls for the plate and hopper to override the automatic hydraulic pressure cut-out.

At first the crew were slow to discharge the hopper and had to wait with full bins until the 18-20sec compaction cycle was completed, but within a few hours they began to tip the mechanism as they were leaving the vehicle — an empty hopper being available when they returned with a full bin.

If the hopper is over-filled rubbish is likely to be pushed onto the road as the sweeping plate starts its action. However, our crew were careful and the problem did not arise.

Dustbins could be loaded rapidly, the hopper taking about 15 bins plus other loose rubbish before it required discharging. After 3 hours 24 minutes of steady working the automatic cut-off came in and we resorted to the override controls. Apart from loose rubbish in cardboard boxes, etc, 517 dustbins had been emptied into the Bulkmaster — a further 99 bin loads filled the body to capacity. Subsequent weighbridge readings showed that the Dennis was still 1 ton below its maximum gvw with 5.4 tonnes (5.3 tons) of rubbish collected.

Discharging the load at the tip was a simple job; the driver only needs to leave the cab to release the tailgate fastenings at each side above the rear wheels. If it is more convenient the locks can be released before reaching the tipping area and not secured until after discharging the load and the vehicle is driven away.

Starting from scratch the discharge procedure takes about 3 mins (including releasing locks). The ejector plate has a box-section protrusion extending from its lower edge and some compressed rubbish clung to it; a few shunts of the ram was sufficient to clear it.

For the total 20.9km (12 mile) route including 8km (5 miles) for the return trip to the tip the Dennis returned a fuel consumption of 1.6km/1(4.5mpg) or 2.8 litres per hour (0.6gal per hour) at an average speed of 4.5km/ h (2.8mph). The low average speed is a fair indication of the estimated 90 per cent idling time.

Workmanlike

In terms of cab design Dennis has adopted a thoroughly workmanlike approach though the layout of instruments and controls could, I feel, be greatly improved. All the instruments and minor controls are grouped on a binnacle directly in front of the driver, and in my view, too far in front for the controls to be comfortably reached. I would prefer to see a neater instrument display with warning lights clearly labelled and grouped together.

The speedometer can be easily seen through the wheel but the smaller air pressure, fuel and alternator charge meter are too easily obscured by the steering-wheel spokes.

The long, cranked gear lever sweeps diagonally across the cab from behind the engine cover toward the driver's seat and though it is within comfortable reach of the driver the very sloppy gate spoils, at least initially, a smooth change. Reverse, second and fourth ratios are all forward of the gate and I found it easy to select reverse or fourth instead of second. However, after a short familiarization period I began to feel my way around the gate and after some practice was able easily to guide the lever into the correct slot. When engaging fourth and fifth ratios the lever brushes against the driver's seat.

Hydrosteer ram-power-assisted steering is fitted and when manoeuvring in tight corners I had to keep the engine at above idling speed to prevent the loss of power assistance especially when the Dennis was barely moving. Otherwise steering was light and precise. Although the vehicle's turning circle was adequate enough, say, when making a three-point turn in a cul-de-sac, I was sometimes caught out on tighter corners when I did not allow sufficient clearance on the approach to clear in one. Turning circle figures are not excessive but I would prefer a better turning circle than the average 18m (60ft) achieved by the Dennis.

The lock actuator park brake valve is nicely positioned relative to the driver and the arrangement of the valve gate provides a useful though perhaps not all-together safe method of holding the vehicle. Instead of repeatedly moving the lever to park, release and off I simply copied the demonstration driver, resting the lever on the bridge between "off' and "park" gate positions.

A quick flick of the wrist to disengage the brake was less tiresome than going through the correct disengagement procedure, especially when it had to be repeated at 10-20yd intervals.

Second gear coped easily with restarting on flat roads and for slow moving the pto could be comfortably left permanently engaged. This was a boon, because the lever is fixed to the cab intersection behind the driver and repeated engage/disengage action would prove tiring. Also the compaction cycle could be completed while the vehicle was moving.

If the mechanical pto selector could be replaced with a simpler air-shift control, it would not only look neater but the valve could be located within easier driver reach.

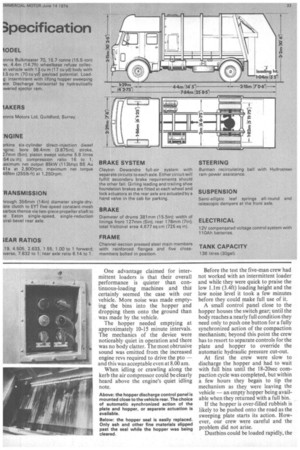

Discharging the load at the rubbish tip is a straightforward operation though the Morse control levers are fiddly to operate. Once the tailgate locks are unfastened, one lifts the tailgate by depressing the longer of the two levers located by the driver's seat. An unfamiliar driver may find it difficult to select the tailgate "hold" position without the gate falling. I tried but had difficulty locating the lever in the hold position which is approximately in the middle of the lever slot.

The ejector plate is powered outward using the second smaller lever. This is spring loaded and firm downward pressure is required to overcome the spring load.

The ram need only be retracted one stage before the tailgate is lowered. Loading can start almost immediately, the plate is shoved progressively rearward by the compacted rubbish.

Care must be taken that the tailgate is not lowered onto the projecting boxsection of the ejector plate.

understand that Dennis engineers are developing a simpler switch system to replace the lever type discharge controls: it would certainly make things easier. So far as the transport manager is concerned the Dennis Bulkmaster is a quiet and efficient vehicle to operate its larger hopper making it suitable for most bulky items such as sofas and cookers as well as normal domestic refuse.

The standard chassis specification simplifies the spares problem though latterly Dennis has had to fit Leyland engines in place of the Perkins ones which are in short supply.

So far as the driver is concerned this vehicle cries out for automatic transmission, I understand that this has been tried but there are transmission cooling problems that must be overcome before it can be a workable proposition. Also on paper a 365mm (14in) clutch doesn't look man enough for the job and Dennis says it is impossible to fit a larger one with the present engine! gearbox arrangement.

Also streamlining of the body controls and an improved instrument layout would make driving easier.

The current cost of the Dennis Bul kmaster is £1 0,875.