TO REDUCE FRICTION IN STEERING GEARS.

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications.

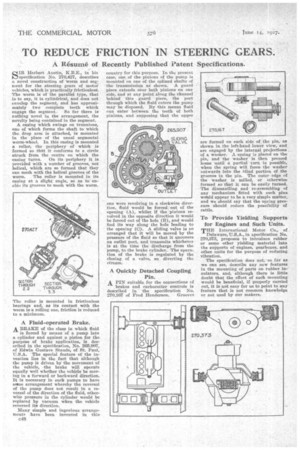

SIR Herbert Austin, K.B.E., in his specification No. 270,427, describes a novel construction of worm and segnient for the steering gears of motor vehicles, which is practically frictionlesd. The worm is of the parallel type, that is to say, it is cylindrical, and does not envelop the segment, and has approximately two complete teeth which

engage the segment. So far there is nothing novel in the arrangement, the novelty being contained in the segment.

A casing which swings on trunnions, one of which forms the shaft to which the drop arm is attached, is mounted in the place of the usual segmental worm-wheel. In this easing is mounted a roller, the periphery of which is formed so that it conforms to a circle struck from the centre on which the casing turns. On its periphery it is provided with a number of grooves, not helical, which are so formed that they can mesh with the helical grooves of the worm. The roller is mounted in its casing at a slight angle, se as to enable its grooves to mesh with the worm.

['he roller is mounted in frictionless bearings and, as its contact with the worm is a rolling one, friction is reduced to a minimum.

A Fluid-operated Brake. A BRAE:E of the class in which fluid

is forced by means of a pump into a cylinder and against a piston for the purpose of brake application, is described in the specification, No. 265,907, of Edwin Gustave Stands, of St. Paul, U.S.A. The special feature of the invention lies in the fact that although the pump is driven by the movement of the vehicle, the brake will operate equally well whether the vehicle be moving in a forward or backward direction. It is necessary in such pumps to have some arrangement whereby the reversal of the pump does not result in a reversal of the direction of the fluid, otherwise pressure in the cylinder would be replaced by vacuum when the vehicle reversed its direction.

Many simple and ingenious arrangements have been invented in this

c48

country for this purpose. In the present case, one of the pinions of the pump is mounted on one of the splined shafts of the transmission as shown. A guard piece extends over both pinions on one side, and at any point along the channel behind this guard piece, the port through which the fluid enters the pump may be disposed. By this means fluid can enter between the teeth of both pinions, and supposing that the upper

one were revolving in a clockwise direction, fluid would be forced out of the opening (A), whilst if the pinions revolved in the opposite direction it would be forced out of the hole (B), and would find its way along the hole /ending to the opening (G). A sliding valve is so arranged that it will be moved by the pressure of the fluid so that it uncovers an outlet port, and transmits whichever is at the time the discharge from the pump, to the brake cylinder. The opera:. tion of the brake is regulated by the closing of a valve, so diverting the stream.

A Quickly Detached Coupling Pin.

PIN suitable for the connections of brakes and carburetter controls is described in the specification No. 270,167 of Fred Henderson. Grooves are formed on each side of the pin, as shown in the left-hand lower view, and are engaged by the internal projections of a washer. A spring is placed on the pin, and the washer is then pressed home until a partial turn is possible, when the spring will force the washer outwards into the blind portion of the grooves in the pin. The outer edge of the washer is milled, or otherwise formed so that it can be easily turned. The dismantling and re-assembling of any mechanism fitted with such pins would appear to be a very simple matter, and we should say that the spring pressure should reduce the possibility of rattle.

To Provide Yielding Supports for Engines and Such Units.

THE International Motor Co., of

Delaware, U.S.A., in specification No. 270,373, proposes to introduce rubber or some other yielding material into the supports of engines, gearboxes, and other units for the purpose of reducing vibration.

The specification does not, so far as we can see, describe any new features in the mounting of parts on rubber insulators, and, although there is little doubt that the effect of such mounting would be beneficial, if properly carried out, it is not easy for us to point to any feature that is not common knowledge or not used by our makers.