HINTS ON MAINTENANCE.

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

Clamping a Daimler Fan Pulley. Gauge-glass Replacement. Removing Maudslay Exhaust-valve Boxes. Compressing a Foden Front Spring.

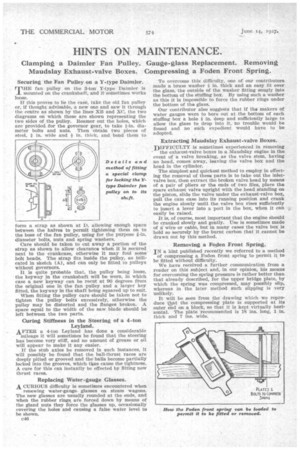

Securing the Fan Pulley on a Y-type Daimler.

r-pHE fan pulley on the 3-ton Y-type Daimler is 1 mounted on the crankshaft, and it sometimes works loose.

If this proves to be the case, take the old fan pulley or, if thought advisable, a new one and saw it through the centre as shown by the lines XS and XC, the two diagrams on which these are shown representing the two sides of the pulley. Reamer out the holes, which are provided_ tor the governor gear, to take i-in. diameter bolts and nuts. Then obtain two pieces of steel, in. wide and in. thick, and bend them to form a strap as shown at D, allowing enough space between the halves to permit tightening them on to the boss of the fan pulley, using for the purpose fin. diameter bolts, nuts and spring washers.

Care should be taken to cut away a portion of the strap as shown to allow clearance when it is secured next to the crankcase, otherwise it may foul some bolt heads. The strap tits inside the pulley, as indicated in sketch (A), and can only be fitted to pulleys without governors.

It is quite probable that, the pulley being loose, the keyway in the crankshaft will be worn, in which case a new keyway can be recut at 90 degrees from the original one in the fan pulley and a larger key fitted, the keyway in the shaft being squared up to suit.

When fitting the pulley care should be taken not to tighten the pulley bolts excessively, otherwise the pulley may be distorted and the flanges broken. A. space equal to the width of the saw blade should be left between the two parts.

Curing Stiffness in the Steering of a 4-ton Leyland.

AFTER a 4-ton Leyland has done a considerable mileage it will sometimes be found that the steering has become very stiff, and no amount of grease or oil will appear to make it any easier.

If the stub axles be removed in such instances, it will possibly be found that the ball-thrust races are deeply pitted or grooved and the balls become partially locked into the grooves, whichthus cause the tightness. A cure for this can instantly be effected by fitting new thrust races.

Replacing Water-gauge Glasses.

A CURIOUS difficulty is sometimes encountered when renewing water-gauge glasses on steam wagons. The new glasses are usually rounded at the ends, and when the rubber rings afe forced down by means of the gland nuts they force the glasses up, occasionally covering the holes and causing a false water level to be shown.

c46 To overcome this difficulty, one of our contributors made a brass washer I in. thick and an easy fit over the glass, the outside of the washer fitting snugly into the bottom of the stuffing box. By using such a washer as this it is impossible to force the rubber rings under the bottom of the glass.

Our contributor also suggests that if the makers of water gauges were to bore out at the bottom of each stuffing box a hole I in. deep and sufficiently large to allow the glass to drop into it, no trouble would be found and no such expedient would have to be adopted.

Extracting Maudslay Exhaust-valve Boxes.

DIFFICULTY is sometimes experienced in removing the exhaust-valve boxes in a Maudslay engine in the event of a valve breaking, as the valve stem, having no head, comes away, leaving the valve box and the head in the cylinder.

The simplest and quickest method to employ in effecting the removal of these parts is to take out the inletvalve box, then extract the broken valve head by means of a pair of pliers or the ends of two files, place the spare exhaust valve upright with the head standing on the piston, slide the valve under the exhaust-valve box, pull the cam case into its running position and crank the engine slowly until the valve box rises sufficiently to insert a lever into a port in the box, when it can easily be raised.

It is, of course, most important that the engine should be cranked slowly and gently. Use is sometimes made of a. wire or cable, but in many cases the valve box is held so securely by the burnt carbon that it cannot be drawn out by this method.

Removing a Foden Front Spring.

IN a hint published recently we referred to a method of compressing a Foden front spring to permit it to be fitted without difficulty.

We have received a further communication from a reader on this subject and, in our opinion, his means for overcoming the spring pressure is rather better than that already described, for the upper bridge plate, by which the spring was compressed, may possibly slip, whereas in the later method such slipping is very

It will be seen from the drawing which we reproduce tat the compressing plate is supported at its outer end on a block, so that it is kept virtually horizontal. The plate recommended is 18 ins. long, 1 in. thick and 7 ins. wide.