SOME NEW IDEAS 'WANG SYSTEMS.

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Stearn Cooling as a Means for Enal Slowly when Stationary. Its Ft Develop ties to Warm Rapidly and to Cool ;sibilities and Present Stage of :ussed.

THE vast majority ef .'!ommercial vehicles is powered with " intemal-combustion " engines, an expressive term which implies that the combustion -of the fuel takes place within the working cylinder itself instead of beneath a separate boiler. This method of using the fuel leads to a high thermal efficiency, among other advantages, but carries with it the drawback that such vulnerable working parts as the pistons, rings and valves have to withstand the high temperature of the flaming gases, which ranges up to 4,000 deg. Fahr. Consequently, in order to safeguard the metal of which these parts are made and to make lubrication of the pistons at all possible, some means for cooling the cylinder head and walls is absolutely essential.

This means for cooling has for many years taken the form of surrounding the combustion chamber and part of the cylinder bore with a jacket of water, the water being circulated rapidly through a radiator in order that its temperature may be kept well below boiling point; in most cases the rate at which water circulation takes place is such that the temperature does not normally exceed 185 deg. Fahr.

The heat which is transferred to the cooling water and dissipated in the radiator represents, of course, a complete loss of energy, and one of the reasons why engines are not now so liable to overheating troubles as was once the case is simply that they make more economical use of the fuel which they use, so that the proportion of the heat which is conveyed to the cooling water is less than is the case with an inefficient engine. Before considering a promising departure from the orthodox cooling system, which forms the subject of this article, it seems appropriate to digress a little concerning this point of engine efficiency.

Quite apart from other advantages, it is obvious that the more compact a combustion chamber can be made the smaller will be the area of cooling surface exposed to the hot gases for a given volume of these gases. Consequently, the old-fashioned T-headed engine, with valves set one at each side a the cylinder bore, had a very inefficient form of combustion chamber of but little depth, the area of cooled metal walls presented to the burning gases being extremely large.

Such a form of combustion chamber compares very unfavourably with the modern Ricardo head for sidevalve engines as regards the ratio of area to volume. This development in combustion chamber design alone has improved the efficiency of the engine very considerably and has correspondingly reduced the amount of heat flowing to the water in the jackets.

In addition to presenting a smaller area for a given volume, the efficient combustion chamber, by promoting turbulence, causes combustion to take place very rapidly, so that it is over and done with almost before the piston begins to descend on its working stroke. Consequently, the time during which the cooled walls c32 are acted upon by burning gases is reduced, which also lessens the work thrown on the cooling system.

It is owing to this point that an engine which is running on an unduly weak mixture tends to overheat—a fact which might seem paradoxical. The reason is, of course, that the weak mixture burns relatively slowly, so that a high temperature is maintained throughout the working stroke right up to the point at which the exhaust valve opens. When this is grasped, it is easy

to see why a weak mixture causes overheating and damaged valves.

Even supposing that the engine is of reasonably efficient design, however, a very large quantity of heat has to be dissipated by the cooling system all the time the engine is running. Roughly speaking, expressed in terms of power, this heat is usually equal to the output of the engine delivered to the clutch shaft. Thus, if the output at the road wheels is 25 b.h.p., then, in round figures, a further 45 H.p, will be

wasted in the exhaust system and another 25 h.p. in the cooling system.

This large..amotint of power applied solely to the heating of the water would very soon cause the water to boil, were it not being circulated rapidly through a radiator in which it is exposed to the cooling action of a flow of air, but the rate at which the water must he circulated is very considerable if boiling is to be avoided. Furthermore, the cooling system is very

VVATER WATER

susceptible to variations in the draught through the radiator, and boiling can fairly readily be brought about by adverse conditions, such as when climbing slowly on bottom gear with a following wind.

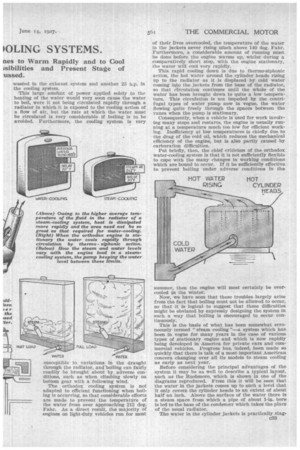

The orthodox cooling system is not adapted to efficient functioning when boiling is occurring, so that considerable efforts are made to prevent the temperature of the water from ever approaching 212 deg. Fehr. As a direct result, the majority of engines on light-duty vehicles run for most of their lives overcooled, the temperature of the water in the jackets never rising Mach above 140 deg. Fahr. Furthermore, a considerable amount of running must be done before the engine warms up, whilst during a comparatively short stop, with the engine stationary, the water will cool very rapidly.

This rapid cooling down is due to thermo-siphonic action, the hot water around the cylinder heads rising up to the radiator as it is displaced by cold water coming into the jackets from the base of the radiator, so that circulation continues until the whole of the water has been brought down to quite a low temperature. This circulation is not impeded by the centrifugal types of water pump now in vogue, the water flowing quite freely through the spaces between the vanes when the pump is stationary.

Consequently, when a vehicle is used for work involving many stops and restarts, the engine is usually running at a temperature much too low for efficient working. Inefficiency at low temperatures is chiefly due to the drag of the cold oil, which reduces the mechanical efficiency of the engine, but is also partly caused by carburation difficulties.

Put briefly, then, the chief criticism of the orthodox water-cooling system is that it is not sufficiently flexible to cope with tile many changes in working conditions which are bound to occur. If it be sufficiently effective to prevent boiling under adverse conditions in the summer, then the engine will most certainly be overcooled in the winter.

Now, we have seen that these troubles largely arise from the fact that boiling must not be allowed to occur, so that it is logical to suggest that these difficulties might be obviated by expressly designing the system in such a way that boiling is encouraged to occur continuously.

This is the basis of what has been somewhat erroneously termed "steam cooling "—a system which has been in vogue for many years in the case of various types of stationary engine and which is now rapidly being developed in America for private cars and commercial vehicles. Progress bas, indeed, been made so quickly that there is talk of a most important American concern changing over all its models to steam cooling as early as next year.

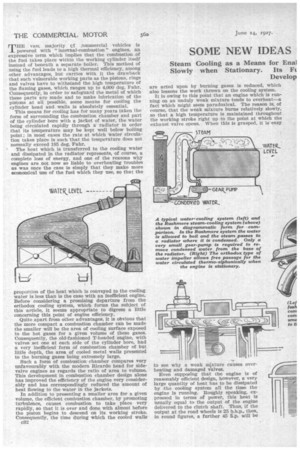

Before considering the principal advantages of the system it may be as well to describe a typical layout, such as the Rushmore, which is shown in one of the diagrams reproduced. From this it will be seen that the water in the jackets comes up to such a level that it only covers the cylinder heads to an extent of about half an inch. Above the surface of the water there is a steam space from which a pipe of about 1-in, bore is led to the base of the condenser which takes the place of the usual radiator.

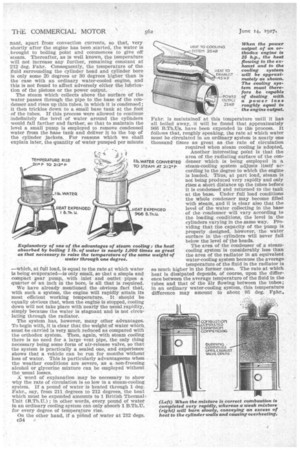

The water in the cylinder jackets is practically stagc,33 nant, apart from convection currents, so that, very shortly after the engine has been started, the water is brought to boiling point and commences to give off steam. Thereafter, as is well known, the temperature will not increase any further, remaining constant at 212 deg. Fahr. Consequently, the temperature of the fluid surrounding the cylinder head and cylinder bore is only some 20 degrees or 30 degrees higher than is the ease with an ordinary water-cooled engine, and this is not found to affect adversely either the lubrication of the pistons or the power output.

The steam which collects above the surface of the water passes through the pipe to the base of the condenser and rises up thin tubes, in which it is condensed; it then trickles down to a small base tank at the foot of the tubes. If this process were allowed to continue indefinitely the level of water around the cylinders would fall farther and farther, so that to maintain the level a small pump is employed to remove condensed water from the base tank and deliver it to the top of the cylinder jackets. For reasons which we shall explain later, the quantity of water pumped per minute

—which, at full load, is equal to the rate at which water is being evaporated—is only small, so that a simple and compact gear pump, with inlet and outlet pipes a quarter of an inch in the bore, is all that is required.

We have already mentioned the obvious fact that, with such a system, the engine will rapidly attain its most efficient working temperature. It should be equally obvious that, when the engine is stopped, Cooling down will not take place with nearly the usual rapidity, simply because the water is stagnant and is not circulating through the radiator.

The system has, however, many other advantages. To begin with, it is clear that the weight of water which must be carried is very much reduced as compared with the orthodox system. Then, again, with steam cooling there is no need for a large vent pipe, the only thing necessary being some form of air-release valve, so that the system is practically a sealed one, and experience shows that a vehicle can be run for months without loss of water. This is particularly advantageous when the weather conditions are severe, as a non-freezing alcohol or glycerine mixture can be employed without the usual losses.

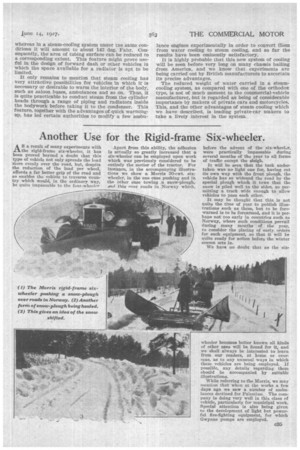

A: word of explanation may be necessary to show why the rate of circulation is so low in a steam-cooling system. If a pound of water is heated through 1 deg. Fehr., say, from 211 degrees to 212 degrees, the heat which must be expended amounts to 1 British Thermal( Unit (B.Th.U.) ; in other words, every pound of water in an ordinary cooling system can only absorb 1 B.Th.U. for every degree of temperature rise. On the other hand, if a ',blind of water at 212 degs. c34 Fahr. is maintained at this temperature until it has all boiled away, it will be found that approximately 966 B.Th.Us, have been expended in the process. It follows that, roughly speaking, the rate at which water must be circulated in an ordinary system is nearly one thousand times as great as the rate of circulation required when steam cooling is adopted, Another interesting point is that the area of the radiating surface of the condenser which is being employed in a steam-cooling system adjusts itself according to the degree to which the engine is loaded. Thus, at part load, steam is not being produced very rapidly and only rises a short distance up the tubes before it is condensed and returned to the tank at the base. Under full load conditions the whole condenser may become filled with steam, and it is clear also that the level of the water collecting in the base of the condenser will vary according to the loading conditions, the level in the cylinders varying in the same way. Providing that the capacity of the pump is properly designed, however, the water surface in the cylinders will never fall below the level of the heads.

The area of the condenser of a steamcooling system is considerably less than the area of the radiator in an equivalent water-cooling system because the average temperature of the fluid in the radiator is so much higher in the former case. The rate at which heat is dissipated depends, of course, upon the difference between the average temperature of the fluid in the tubes and that of the air flowing between the tubes; in an ordinary water-cooling system, this temperature difference may amount to about 95 deg. Fiihr., whereas in a steam-cooling system uncier tne same conditions it will amount to about 142 deg. Fahr. Consequently, the area of tubing surface can. be reduced to a corresponding extent. This feature might prove useful in the design of forward dash or other vehicles in which the space available for a radiator is apt to be limited.

It only remains to mention that steam cooling has very attractive possibilities for vehicles in which it is necessary or desirable to warm the interior of the body, such as saloon buses, ambulances and so on. Thus, it is quite practicable to conduct steam from the cylinder heads through a range of piping and radiators inside the bodywork before taking it to the condenser. This feature, together with the advantages of quick warmingup, has led certain authorities to modify a few ambu

lance engines experimentally in order to convert fffem from water cooling to steam cooling, and so far the results have been eminently satisfactory.

It is highly probable that this new system of cooling will be seen before very long on many chassis hailing from America, and we know that experiments are being carried out by British manufacturers to ascertain• its precise advantages.

The reduced weight of water carried in a steamcooling system, as compared with one of the orthodox type, is not of much moment to the commercial-vehicle manufacturer, but is regarded as being of considerable importance by makers of private cars and motorcycles. This, and the other advantages of steam cooling which we have described, is leading private-car makers to take a lively interest in the system.