Better Braking

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

with Less E

ort

„Jr. secure consistent high-efficiency braking with comparatively little manual effort on maximum-load lorries and the heavier passenger chassis has always been a thorny problem for

vehicle designers. Loads and speeds have then, especially in models sent overseas, where the difficulty, is increased yet again in mountainous areas with long descents.

• Brake manufacturers have introduced efficient compressed-air and hydraulic power-assistance units . which have lessened pedal effort and given a high boost at the brake Cams to operate the shoes, and facings with lower coefficients of friction have been evolved to give longer life and reduce fade. at high temperatures. Whilst the foot brake can be boosted to give adequate retardation with these facings, art appreciable manual effort is required to operate the hand brake, which is already high on many of the existing earn systems.

The Girling technicians have been

studying the braking problems of heavies,both on the drawing board and in operation, in this country and, overseas. From their experience, a new two-leading-shoe braking system has h,:en introduced for the larger goods and passenger vehicles, one of the advantages of the extra-heavy-duty ...quipment being that it can be operated through the normal camshaft.

The type of brake cam used does riot sacrifice efficiency, and, taken in :onjunction with the two-leading-shoe arrangements, requires approximately 40 per cent, less input for an output equal to that of the normal cam system.

The two-leading-shoe arrangement is based on the Girling principle used in cars, vans and light lorries, but is sturdier in construction. Provision is made to operate the system mecb1nically with vacuum assistance, hydraulically, or by compressed air.

To increase mileage between adjustment and to allow for the expansion of

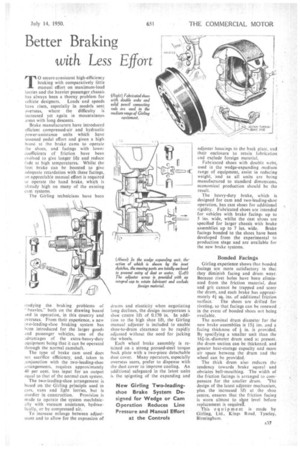

drams and elasticity when negotiating long declines, the design incorporates a shoe centre lift of 0.170 in. In addition to the high shoe lift, the Girling manual adjuster, is included to enable shoe-to-drum clearance to be rapidly adjusted without the need for jacking the wheels.

Each wheel brake .assembly is retained on-a strong pressed-steel torque back plate with a two-piece detachable dust cover. Many operators, especially overseas users, prefer to dispense with the dust cover to improve cooling. An additional safeguard in the latest units is the spigoting of the expanding and adjuster housings to the back plate, and their enclosure to retain lubrication and exclude foreign material.

Fabricated shoes with double webs, used in the wedge-expanding inediuni range of equipment, assist in reducing weight, and as all units are being manufactured to standard dimensions, economical production should be the result.

. The heavy-duty brake, which is designed for cam and two-leading-shoe operation, has cast shoes for additional rigidity. Fabricated shoes are intended for vehicles with brake facings up to 5 ins, wide, whilst the cast shoes are specified for larger chassis with brake

assemblies up to 7 ins. wide. Brake facings bonded to the shoes have been developed from the experimental to production stage and are available for the new brake systems.

Bonded Facings

Girl hug experience shows that bonded -facings are more satisfactory in that they diminish facing and drum wear: Because rivet holes have been eliminated from the friction material, dust and grit cannot be trapped and score the drum, and each brake has approximately 4i sq. ins. of additional friction surface, The shoes are drilled for riveting, so that facings can be renewed in the event of bonded shoes not being available.

The nominal drum diameter for the new brake assemblies is 15i ins, and a

facing thickness of in. is .provided. By specifying a smaller unit than the 161-in.-diameter. drum used at present, the drum section can be thickened, and . greater beat-storage capacity and more air space between the drum and the wheel can be .provided.

The thiek drum also reduces the tendency towards brake squeal and obviates hell-mouthing. The width of the friction facings is arranged to compensate for the smaller drum. "the design of the latest adjuster mechanist-it, plus the increased lift at the shoe centre, ensures that the friction facing is worn almost to slaoe level before replacement is required.

This equip me nt is made by Girling, Ltd., Kings Road, • Tyseley, Bi rmingha