WARIVIING TO THE

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

COLD WAR

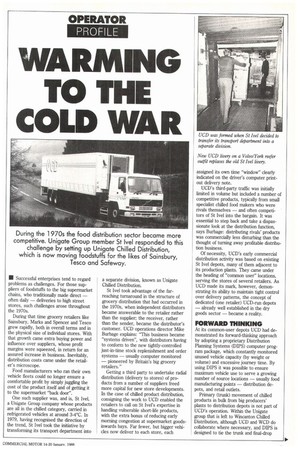

• Successful enterprises tend to regard problems as challenges. For those suppliers of foodstuffs to the big supermarket chains, who traditionally made direct — often daily — deliveries to high street stores, such challenges arose throughout the 1970s.

During that time grocery retailers like Sainsbury, Marks and Spencer and Tesco grew rapidly, both in overall terms and in the physical size of individual stores. With that growth came extra buying power and influence over suppliers, whose profit margins were squeezed, in return for an assured increase in business. Inevitably, distribution costs came under the retailer's microscope.

Food manufacturers who ran their own vehicle fleets could no longer ensure a comfortable profit by simply juggling the cost of the product itself and of getting it to the supermarket "back door".

One such supplier was, and is, St lye!, a Unigate Group company whose products are all in the chilled category, carried in refrigerated vehicles at around 3-4°C. In 1979, having recognised the direction of the trend, St lye! took the initiative by transforming its transport department into a separate division, known as Unigate Chilled Distribution.

St lye' took advantage of the farreaching turnaround in the structure of grocery distribution that had occurred in the 1970s, when independent distributors became answerable to the retailer rather than the supplier; the receiver, rather than the sender, became the distributor's customer. UCD operations director Mike Burbage explains: "This business became "systems driven", with distributors having to conform to the new tightly-controlled just-in-time stock replenishment and order systems — usually computer monitored — pioneered by Britain's big grocery retailers."

Getting a third party to undertake radial distribution (delivery to stores) of products from a number of suppliers freed more capital for new store developments. In the case of chilled product distribution, consigning the work to UCD enabled the retailers to call on St Ivel's expertise in handling vulnerable short-Ede products, with the extra bonus of reducing early morning congestion at supermarket goodsinwards bays. Far fewer, but bigger vehicles now deliver to each store, each assigned its own time "window" clearly indicated on the driver's computer printout delivery note.

UCD's third-party traffic was initially limited in volume but included a number of competitive products, typically from small specialist chilled food makers who were rivals themselves — and often competitors of St lyel into the bargain. It was essential to step back and take a dispassionate look at the distribution function, says Burbage: distributing rivals' products was commercially less disturbing than the thought of turning away profitable distribution business.

Of necessity, UCD's early commercial distribution activity was based on existing St Ivel depots, many of them adjacent to its production plants. They came under the heading of "common user" locations, serving the stores of several retailers. As UCD made its mark, however, demonstrating its ability to maintain tight control over delivery patterns, the concept of dedicated (one retailer) UCD-run depots — already well established in the dry goods sector — became a reality.

FORWARD THINKING

At its common-user depots UCD had demonstrated its forward-thinking approach by adopting a proprietary Distribution Planning Systems (DIPS) computer program package, which constantly monitored unused vehicle capacity (by weight or volume) and excessive journey time. By using DIPS it was possible to ensure maximum vehicle use to serve a growing number of source locations — usually food manufacturing points — distribution depots, and retail outlets.

Primary (trunk) movement of chilled products in bulk from big producers' plants to distribution depots is not part of UCD's operation. Within the Unigate group that is left to Wincanton Chilled Distribution, although UCD and WCD do collaborate where necessary, and DIPS is designed to tie the trunk and final-drop