FODEN'S TIP FOR THE TOP

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

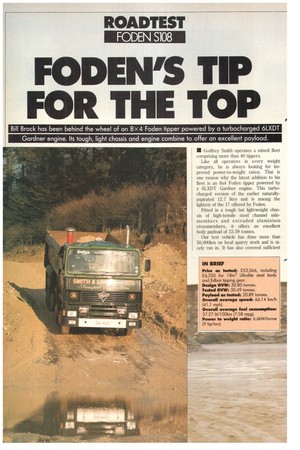

Bill Brock has been behind the wheel of an 8x4 Foden tipper powered by a turbocharged 6LXDT Gardner engine. Its tough, light chassis and en•ine combine to offer an excellent payload.

• Godfrey Smith operates a mixed fleet comprising more than 40 tippers.

Like all operators in every weight category, he is always looking for improved power-to-weight ratios. That is one reason why the latest addition to his fleet is an 8x4 Foden tipper powered by a 6LXDT Gardner engine. This turbocharged version of the earlier naturallyaspirated 12.7 litre unit is among the lightest of the 17 offered by Foden.

Fitted in a tough but lightweight chassis of high-tensile steel channel sidemembers and extruded aluminium crossmernbers, it offers an excellent body payload of 22.59 tonnes.

Our test vehicle has done more than 50,000km on local quarry work and is nicely run in. It has also covered sufficient ground for some of its less endearing qualities to manifest themselves.

• BRAKING

Soon after leaving the company's Ardley quarry with a full load grossing 30.48 tonnes we stopped off at the Department of Transport's test station Bicester to obtain a printout of the vehicle's brake performance on a rolling brake test machine. The figures showed a bias to the rear axles and an overall efficiency of less than 40%. We were subsequently able to substantiate these results with dynamic tests at the MIRA track where even wider full application none of the axles came anywhere near wheel locking.

Despite deficiencies in performance the foot pedal does have a progressive response and under normal road use supplies smooth, controlled braking without deviation.

Following the test the operator told us that in his experience non-asbestos brake linings fitted as original equipment tend to deteriorate in use: it is his practice to replace them with asbestos linings as they become worn.

• PERFORMANCE

Over motorway and A road sections of our test route the 201kW engine produced a lively performance, resulting in fast journey times averaging 66.14km/h overall. Motorway speeds of around 96km/h are achieved at about 1,800rpm while the high torque backup of 1,140Nm at 1,300rpm enables the engine to pull down to around 1,150rpm — corresponding to a road speed of 64km/h — without labouring. This makes it possible to remain in the fastest gear for most of the time.

Most hills on our route were tackled with a drop of only one or two cogs. The lowest gear selected for the steepest and longest gradient, the timed hill climb, was fourth. A time of three minutes is more than 10% faster than that of a Cummins LIO 250-powered Seddon Atkinson.

Fast journey times are rarely accompanied by record fuel returns. So it is here, with a consumption of 37.27iit/100km (7.58mpg). High speed running increased the fuel consumption running to 41.5 lit/10 Okm (6.8inpg), but it fell to 34.5lit/100km (8.19mpg) over the more sedate urban section.

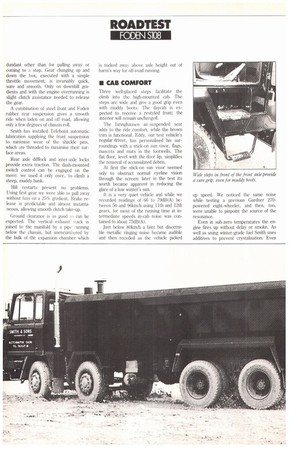

On downhill sections excess speed has to be checked using the service brakes and gearbox: an exhaust brake is not yet available for this engine option.

• TRANSMISSION

Eaton's Twin Splitter transmission, now in full production, is becoming a regular feature on our test vehicles. We have been critical of prototype and early production units, but the one fitted here, perhaps because it is well run in, works in textbook fashion. Clutch operation, for whole-gate or split changes, is almost re dundant other than for pulling away or coming to a stop. Gear changing up and down the box, executed with a simple throttle movement, is invariably quick, sure and smooth. Only on downhill gradients and with the engine overrunning is slight clutch assistance needed to release the gear.

A combination of steel front and Foden rubber rear suspension gives a smooth ride when laden on and off road, allowing only a few degrees of chassis roll.

Smith has installed Telehoist automatic lubrication supplying the front suspension to minimise wear of the shackle pins, which are threaded to maximise their surface areas.

Rear axle diftlock and inter-axle locks provide extra traction. The dash-mounted switch control can be engaged on the move: we used it only once, to climb a steep, muddy bank.

Hill restarts present no problems. Using first gear we were able to pull away without fuss on a 25% gradient. Brake release is predictable and almost instantaneous, allowing smooth clutch take-up.

Ground clearance is as good can be expected. The vertical exhaust siack is joined to the manifold by a pipe running below the chassis, but unencumbered by the bulk of the expansion chamber which is tucked away above axle height out of harm's way for off-road running.

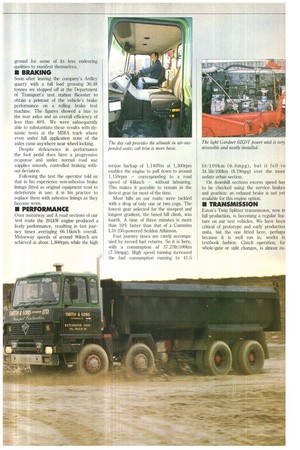

• CAB COMFORT Three well-placed steps facilitate the climb into the high-mounted cab. The steps are wide and give a good grip even with muddy boots. The daycab is expected to receive a restyled front; the interior will remain unchanged.

The I sringhau sen air-suspended seat adds to the ride comfort, while the brown trim is functional. Eddy, our test vehicle's regular driver, has personalised his surroundings with a stick-on sun visor, flags, mascots and mats in the footwells. The flat floor, level with the door lip, simplifies the removal of accumulated debris.

At first the stick-on sun visor seemed only to obstruct normal eyeline vision through the screen: later in the test its worth became apparent in reducing the glare of a low winter's sun.

It is a very quiet vehicle and while we recorded readings of 66 to 79dB(A) between 50 and 96km/h using 11th and 12th gears, for most of the running time at intermediate speeds in-cab noise was contained to about 75dB(A).

Just below 80km/h a faint but discernible metallic ringing noise became audible and then receded as the vehicle picked up speed. We noticed the same noise while testing a previous Gardner 270powered eight-wheeler, and then, too, were unable to pinpoint the source of the resonance.

Even in sub-zero temperatures the engine fires up without delay or smoke. As well as using winter-grade fuel Smith uses additives to prevent crystalisation. Even so, some vehicles on his fleet experienced problems in the recent cold spell — but our Foden, fitted with a 300 watt Thermoline heater, was not among them. The heater can be switched on before starting the engine to ensure that lines and filters remain free flowing. 'Me engine soon reached normal operating temperatures but the cab's interior remained chilly as the heater proved barely able to cope with such extreme conditions.

Daily level checks are carried out below the front grille and where access to the engine is needed the cab tilts a long way forward. Sadly the capacity of the hand-operated hydraulic pump is small, making the raising and lowering operations laborious. As the cab moves into the final stages of towering, relocation of the cab locks need close attention as they do not always line up automatically. The Foden's power steering is light but the steering axle tyres, almost certainly relocated from the drive axles, tend to follow ruts and other irregularities.

When we discharged the load it proved to be stubborn, sticking until the Neville Charroid steel body was almost fully tipped, but the Edbro tipping gear coped well without any sign of strain. The PTO switch automatically knocks out as soon as the tipping lever is released, ensuring that the vehicle is not driven more than a short distance with the auxiliary gearing engaged.

Part of the load refused to budge and needed to be freed manually. The shovel was taken from its strap and the folding ladder and step inside the body made the climb an easy and safe operation.

• SUMMARY

Built to order, the Foden S108 fitted with the Gardner 270 engine option is very light, but it doesn't come cheap. The engine adds 2,466 to the basic S108 chassis price, and the Eaton Twin Splitter transmission costs a further ,530.

The high power and torque levels, combined with a very simple gearbox operation, make for relaxed driving. Fuel consumption did not meet our expectations, but may fare comparatively better in a more arduous environment.

M by Bill Brock