AN ENGINE OPERATING ON A NEW PRINCIPLE,

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

Super-compression Permitted by Utilizing Cooled Air or Mixture from a Compression and Expansion Chamber.

WHAT appears to be a new principle is embodied in a remarkable

internal-combustion engine invented by Mr. 0. W. Hult, chief engineer of the Aktieholaget Archimedes, Stockholm, who is already well known as the designer of the Archimedes outboard motors.

The chief point in the invention is that the bulk of the air or mixture is

considerably cooled in a special apparatus before being admitted into the cylinder. or cylinders of the engine, thus enabling a much higher compression ratio to be employed with a consequent gain in the efficiency of the engine. Apart from this cooling apparatus the engine closely resembles an ordinary type con-. structed on the four-strokecycle principle, and for the sake of simplicity in describing it w will deal with a unit possessMg one cylinder only.

Tho highest useful compression ratio employed in ordinary petrol engines running at reasonable speeds on a good grade of commercial petrol is in the neighbourhood of 5 to 1, but actual tests with a small twoc3iinclered experimental engine having a compression ratio of 8 to 1 have given sonic most interesting results.

At a brake mean effective pressure of 135 lb. per sq. in. (9.5 kg. per sq. cm.) the fuel consumption was .5 pt. (203 grammes) per b.h.p.-hour, and at 11.5 lb. (SA kg.) it was .474 pt. (192 grammes). In an ordinary petrol engine of good design the corresponding figures may be said to average .59 pt. at 90 lb. per sq. in.

In another engine which is now being built the inventor intends to use a still higher compression ratio, and, it is hoped, without a correspondingly decreased fuel consumption. Any system for procuring the cold air or mixture, e.g., a compressien machine for use with ammonia or some other refrigerant, or an absorption device utilizing the heat from the exhaust products of the engine, is theoretically adoptable, but after thorough investigation the inventor" is convinced that, in practice, these are not satisfactory.

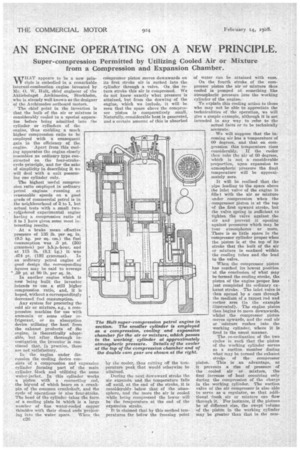

In the engine under diecussion the cooling device consists of a compression and expansion cylinder forming part of the main cylinder block and utilizing the same water-jacket. In this cylinder works a piston with a connecting rod, the big-end of vih rich bears on a crankpin of the common crankshaft, and the cycle of operations is also four:stroke. The head of the cylinder takes the form of a cooling plate in which is a large lumber of fine water-cooled copper thimbles with their closed ends projecting into the water space. When the

coMpressor piston moves downwards on its first stroke air is sucked into the cylinder through a valve. On the return stroke this air is compressed. We do not know exactly what pressure is attained, but from the drawing of the engine, which. we. include, it will be. seen that the space above the compressor piston is comparatively small. Naturally, considerable heat is generated, and a certain amount of this is absorbed by the cooler, thus cutting off the tentperature peak that would otherwise be attained.

During the next downward stroke the air expands, and the temperature falls off until, at the end of the stroke, it is considerably below that of the atmosphere, and the more the air is cooled while being compressed the lower will be the temperature at the end of the expans ion stroke.

It is claimed that by this method temperatures far below the freezing point of water can be attained with ease. On the fourth stroke of the compressor piston the air or mixture thus cooled is pumped at something like atmospheric pressure into the working cylinder of the engine.

To explain this cooling action to those who may not be able to appreciate the technicalities of the operation, we will give a simple example, although it is not intended in any way to refer to the actual facts or to be technically accurate.

We will suppose that the incoming air has a temperature of 60 degrees, and that on coin nression this temperature rises considerably. If the cooler then robs the air of 60 degrees, which is not a considerable proportion, upon expansion to atmospheric pressure the final temperature will be approximately zero.

It will be realized that the pipe leading to the space above the inlet valve of the engine is fillet with the air or mixture under compression when the compressor piston is at the top of the first upward stroke, but the valve spring is sufficient to tighten the valve against the air and prevent it opening against pressures which may be four atmospheres or more. There is so little space in the compressor cylinder proper when the piston is at the top of its stroke that the bulk of the air or mixture is confined within the cooling tubes and the lead to the valve.

When the compressor piston has reached its lowest position at the conclusion of what may be termed the cooling stroke, the piston of the engine proper has just completed its ordinary exhaust stroke. The inlet valve is then opened by a cam through the medium of a tappet rod and 'rocker arm (in the example illustrated). The engine piston then begins to move downwards, whilst the compressor piston moves upwards, and the cool air or mixture rushes into the working cylinder, where it is fired in the nsual manner.

The co-ordination of the two cycles is such that the piston of the working cylinder serves as a suction member during what may be termed the exhaust stroke of the compressor piston. This " is an advantage, as it prevents a rise of pressure of the cooled air or mixture, the first increase of heat occurring only during the compression of the charge in the working cylinder. The suction valve of the. air compressor is also able to serve as a regulator, so that additional fresh air or mixture Can flow through it. " For instance, if the pistons he of different size, the swept •veltune of the piston in the working cylinder may be greater than that in the coal

pressor cylinder ; consequently, when suction occurs the air or mixture may be rarefied to, say, .9 of the atmospheric pressure, in which case further air or mixture is drawn in through the suction valve.

It has been found unnecessary to operate the suction valve pokidvely, but it may be necessary to govern it positively in order to take advantage of the control permitted by the method just outlined.

The regulation of the admission of air or mixture may also be arranged in such a manner that the degree of charging in the working cylinder of the motor is determined independently of the greater or lesser volume of the compressor, e.g., in such manner that the motor when running normally receives only so mueh air or mixture as finds room in the compressor cylinder, in which case the working cylinder receives a 73 per cent.

charge, which corresponds to the increased condensation of the air or mixture as a consequence of being cooled to 0 degrees C. at the beginning of the compression in the working cylinder. If desired an extra section valve can be provided to give a greater degree of charging or a complete charge and allowing the entrance of air or mixture during the whole suction stroke of the working piston if, in case of need, all increase in the volumetric efficiency of the engine be desired.

The compressor may be provided -with two or more pistons located in a corresponding number of cylinders, or it may be double-acting, as for use in the case of a motor running on the two-strokecycle principle, or with a two-cylindered four-stroke-cycle motor with a compressor common to the two cylinders.

This engine and the principle involved certainly appear to possess great poten tialitiea. It may be that difficulties will occur with carburation, as we are inclined to think that condensation ia liable during the expansion stroke when the temperature is lowered considerably below that of the atmosphere, but it may be that the heat generated during the first compression. would result ii vaporizing the fuel so effectively that any considerable condensation might be obviated. However, actual tests will be the only means for solving this problem.

For an engine operating at a wide range of speeds, as in the case of units employed on commercial vehicles, it is possible that the rarefaction of the mixture at small throttle openings would affect the working, but it is difficult, without actual test, to express any definite opinions, and we think that the new unft is well worth the practical investigation and consideration of our engine mannfacturers.