HINTS ON MAINTENANCE.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CONTRIBUTIONS are invited for this page from mechanics, works staff and draughtsmen, and fleet managers, drivers, garage foremen, and will be paid for on a generous scale. Every system; make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, beaded "Roadside and Garage." Communications Should be addressed to "The Editor, Tlte Commercial Motor, 7-15, Rosebery Avenue, London, E. C. 1."

165.—Increasing the Compression on 31-4 ton Subsidy Type Dennis.

During the war the mechanical transport authorities desired that the compression , of the engine utilized on the 34-4 ton type Dennis should be lowered. This naturally reduced the power and increased the petrol consumption, and owners of these vehicles who

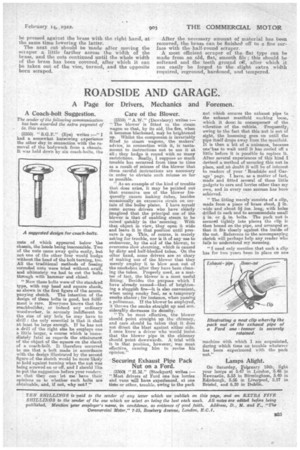

This diagram of a Dennis valve cap indicates the dimensions which will assist in obtaining the most efficient compression pressure. The old caps should be altered accordingly.

are desirous of restoring their engines to their original condition may do so quite easily in the following manner :— The centre inspection plug immediately above each piston will be found to have been hollowed out, and should be replaced by a new solid plug, which can be procured direct from the makers. The valve caps should also be changed for others which comply with the measurements given in the accompanying diagram. Valve caps which are unsuitable may readily be changed by measuring the distance they project above the cylinders. This will be in. instead of Ai. in., as is noted on the illustration. If the flange is in. thick, it should be reduced by A. in. on its underside, thus letting the cap screw farther into the combustion chamber ; at the same time A. in. must be removed from the thread of the cap, as, failing this, the valve, when fully lifted by the cam, may strike the bottom of the valve cap, probably with serious consequences.

The re-machining may be carried out by the owner or by a local garage, or, failing this, the caps should be sent, carriage paid, to the makers. Incidentally, the cost of correction is not expensive, and the saving of petrol, due to the increased power, will soon be appreciated. When the engine is restored to its normal condition, it is probable that it will not be able to take the full ranee , of advance given by the ignition quadrant ; however, Owever this is only a small matter, which can easily be dealt with by the driver.

166.—The Lubrication of Brake Joints.

Among the details of motor vehicles which suffer from neglect, the most pronounced are probably brake joints. So long as the brakes serve effectively, the average driver allows the joints of the rods and levers to take care of themselves. All may be well until the necessity arises for the joints to be uncoupled, when, as a rule, they will be found firmly n34 rusted up and in many cases immovable until paraffin has been applied to them and allowed many hours to soak in. If, however, once a week two or three drops of oil be applied to the exteriors of the various brake joints, trouble of this nature will be obviated. Not only so, but wear of the pins and eyes will be considerably reduced, and if the brake shaft bearings be similarly treated, brake efficiency will be increased by the reduction of friction.

It is also a good idea occasionally to apply two or three drops of oil to the threads of brake adjusters, even although the latter may not require to be taken up. The oil facilitates operations when an adjustment becomes necessary by preventing the formation of rust at exposed points.

167.—Scraping the Big-end Brasses of Steam

Wagons.

When it becomes necessary to scrape or relieve the horns of a connecting rod brass of the engine of a steam wagon, instead of using the ordinary halfround scraper, an easier and quicker way is to utilize a fiat scraper in conjunction with a block of hard wood cut to the same radius as each brass and riot less than the, latter in length. The flat scraper should be drawn out rather thin at the end and the corners slightly rounded. The latter operation can be performed on the oilstone after the tool has been hardened and ground. The brass to be operated upon should be held securely in the vice and the block of wood laid in the radius so that it can rock freely in the brass. The scraper should now be laid on the top of the block of wood and held down with the fingers of the left hand, whilst the right hand grasps the handle. If the right hand is now raised, the cutting edge of the scraper is lowered ; at the same time the wood block swivels with the tool, and the scraper should be pressed against the brass with the right hand, at the same time lowering the latter. The next cut should be made after moving the scraper a little farther across the width of the brass, and the cuts continued until the whole width of the brass has been covered, after which it can be taken out of the vice, turned, and the opposite horn scraped. After the necessary amount of material has been removed, the brass can be finished off to a fine surface with the half-round scraper. A most efficient scraper of the• flat type can be made from an old, fiat, smooth file; this should be softened and the teeth ground off, after which it can easily be forged to the slight extra width required, reground, hardened, and tempered.