Dorman V8 for heavy trucks

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

An oversquare diesel developing 235 bhp is the first of a new series of engines with outputs up to 600 bhp.

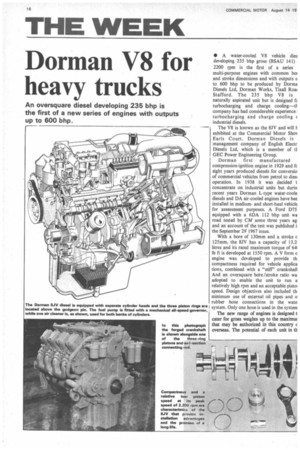

• A water-cooled V8 vehicle dies developing 235 bhp gross (BSAU 141) 2200 rpm is the first of a series multi-purpose engines with common bot and stroke dimensions and with outputs u to 600 bhp to be produced by Dorms Diesels Ltd, Dorman Works, Tixall Row Stafford. The 235 bhp V8 is naturally aspirated unit but is designed fc turbocharging and charge cooling—tt company has had considerable experience turbocharging and charge cooling c industrial diesels.

The V8 is known as the 8.1V and will I exhibited at the Commercial Motor Shay Earls Court. Dorman Diesels is management company of English Eectr Diesels Ltd, which is a member of tt GEC Power Engineering Group.

Dorman first manufactured compression-ignition engine in 1929 and fc eight years produced diesels for conversio of commercial vehicles from petrol to dies■ operation. In 1938 it was decided t concentrate on industrial units but durin recent years Dorman L-type water-coole diesels and DA air-cooled engines have bee installed in mediumand short-haul vehicle for assessment purposes. A Pord D75 equipped with a 6DA 112 bhp unit wa road tested by CM some three years ag and an account of the test was published i the September 29 1967 issue.

With a bore of 130mm and a stroke c 125mm, the 8JV has a capacity of 13.2 litres and its rated maximum torque of 641 lb ft is developed at 1550 rpm. A V form engine was developed to provide th compactness required for vehicle applica tions, combined with a "stiff" crankshafi And an oversquare bore/stroke ratio wa adopted to enable the unit to run a relatively high rpm and an acceptable pistol speed. Design objectives also included th minimum use of external oil pipes and o rubber hose connections in the wate system. Only one hose is used in the system The new range of engines is designed t cater for gross weights up to the tnazimw that may be authorized in this country c overseas. The potential of each unit in tl ieries for uprating by turbocharging, with or without charge cooling, will extend its power putput range to cater for considerable variaions in user requirements in every category.

The dry weight of the unit is approximately 27001b and its weight:0-power ratio is, therefore, around 1.1.51b /bhp, the output per cylinder being approximately 30 bhp. A rating of 600 bhp will apply to turbocharged /charge-cooled V12 engines and this rating (of 60 ,hp /cylinder) is indicative of the potential mtputs of all the units in the range. At their igher ratings, the units will have a weight-to-power ratio of around 7.41b /bhp which is comparable with that of typical urbocharged engines of 300 bhp (plus) woduced in this country and overseas.

The crankcase/cylinder block unit is a well-ribbed iron casting, the blocks being atted with centrifugally cast and hardened wet cylinder liners having three 0-type ;ealing rings and a weep hole. Individual .1ylinder heads are employed for simplified ;ervicing and they are fitted with replaceable falve-seat inserts and valve guides. Located n the centre of the V, the single five-bearing :amshaft is of high-duty cast iron and has :hilled cams. There are two valves per :ylinder, operated by chill-hardened :ast-iron tappets, tubular push rods and

.ockers. The rockers are cast in high-duty ron and all working surfaces are hardened. 7orged from EN195 steel, the crankshaft las integral balance weights, the crank pins and journals being induction hardened. End location of the shaft is by steel thrust strips raced with reticular aluminium tin, located 3n each side of the rear main hearing.

The side-by-side connecting rods are "-section stampings in EN 16T steel. To allow withdrawal through the cylinder the ig end is split at an angle and location of he cap is provided by serrations, retention )eing by two 16mm dia bolts. The centreo-centre distance of the connecting rod is ?.66mm, the small-end bearing being a wrapped steel bush lined with bronze.

The pistons are of high silicon alloy with toroidal combustion chamber in the crown, he two compression rings and one oil .lontrol ring being located above a 50mm dia blly-floating gudgeon pin retained by circlips. Df 115mm and 95nun dia respectively, the nain and big-end bearings are of the thin neel-backed type lined with reticular aluminium tin. The hardened timing and auxiliary gears are of the single-helical type and are located at the front of the engine.

The lubricant from a large-capacity ;ear-type oil pump is passed through a vater-cooled "stabilizer", a relief valve and paper element filter to the main oil gallery, roan which it is fed to the crankshaft, :amshaft, connecting-rod bearings, timing

;ears and valve gear. Oil cooling the pistons ias been shown to be unnecessary for the

ngine in its naturally aspirated form. The amp is an aluminium casting with a :apacity of 7.5 gal.

A conventional jerk-type fuel pump has a nechanical all-speed governor which is ocated in the V, and there is space for an air compressor in the fuel-pump drive. qulti-hole injectors are fitted in accessible