Valve Seat Truer of Lasting Precision

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

SOMETIMES there is more interest in a smallmechanical detail than in a major matter of design. An example is afforded by an improvement that has recently been evolved for one of those well-known items of maintenance equipment widely associated with the name Black and Decker. The tool in point is a valve-seat resurfacer.

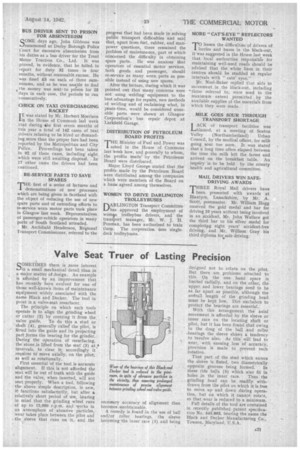

The principle on which such tools operate is to align the grinding wheel or cutter (2) by centring it from the valve guide. To do this a stud or shaft (4), generally called the pilot, is fitted into the guide and its projecting part forms the bearing for the grinder. During' the operation of resurfacing, the stone is lifted from the seat (3) at! intervals, to clear it; accordingly it . requires to move axially, on the pilot; as well as rotationally.

First essential of the tool is accurate alignment. If this is not afforded the seat will be out of truth with the guide and the valve, when inserted, will not seat properly. When a tool, following the above simple description, is new, it functions satisfactorily, but after a relatitely short period of use, bearing in mind that the grinding wheel runs at up to 12,000 r.p.m. and works in an atmosphere of abrasive particles, wear takes place between the pilot and the sleeve that runs on it, and the

necessary accuracy of alignment then • becomes unobtainable.

A remedy is found in the use of ball and/or roller bearings, the sleeve becoming the inner race (1) and being

designed not to rotate on the pilot. But there are problems attached to • this. 94 the one hand space is limited radially, and on the other, the upper and lower bearings need to be as far apart as possible, although the overall length of the grinding head must be kept low. Dirt excluders to protect the bearings are essential.

With this arrangement the axial movement is afforded by the sleeve or inner race on the locating shaft or pilot, but it has been found that owing to the drag of the ball and roller -bearings the sleeve shows a tendency to -revolve also. As this will lead to wear, with ensuing loss of accuracy. provision is made to prevent such rotation.

That part of the stud which enters the sleeve is fluted, two diametrically opposite grooves being formed. In these ride halls (5) which also fit in holes in the inner race. Thus the grinding head can be readily withdrawn from the pilot on which it is free to mcive up and down during operation, hut on which it cannot rotate, so that wear is reduced to a minimum. '

Full details of the tool are contained in recently published patent specifics' tion No. 545,883, bearing the -name the Black and Decker Manufacturing .Co"., Towson, Maryland, U.S.A.