Fr 0 m Drivers kMechanics

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send ?a an account of d y sPecial incident of your work or exPerience. If suitable, we will edit your notes, suPfily a sketch wizen required, and pay you for everything published. Mention your employer's in confidence, as evidence of good faith. 4 ddress to The Editor, THL: COMMERCIAL MOTOR, Rosebery Avenue, London, E.G.

Repair to a Broken Valve Stern.

[1:302] " G.S." (Battersea) writes :—" Whilst out on a journey recently I had trouble through an exhaust valve breaking off at the cotter-hole, and having no spare with me at the time I effected the following repair.

" All the valves being interchangeable, I replaced an inlet valve for the broken exhaust, and happening, to have a very light valve spring in my tool-kit exchanged this with the original exhaust spring. To keep the lighter spring in place I opened out the broken end of the valve stem after fitting a washer. Upon starting the engine the repaired valve worked quite satisfactorily as an automatic inlet and so got me home.

For Turning Concentric Work.

The sender of the fallowing COMMUltication has been awarded the Ws. prize this week.

[1303] " .A.P . T." (Sa.ndbach) writes :—" We recently had a special job to turn out a large number of thin brass liners, and it was essential that the bore should be strictly concentric with the outside diameter. The comparatively short length of grip obtainable with the ordinary form of jaw chuck, also the likelihood of springing setting up whilst the liners were being machined, caused me to devise a chuck upon the following lines :— "I prepared a cast-iron body and screwed it to suit the lathe spindle ; it was then slotted at 120 degrees to accommodate three hardened steel blades. The body was then bored out to take a sliding cone piece, into which the blades were fitted. I next procured a handwheel of a slightly smaller diameter than the bore of the liners, to enable the latter to be put in position on the chuck, and then fitted a screwed spindle into the sliding cone. By slightly turning the handwheel in either the one direction or the other, the cone could be given a sliding movement, causing the blades to grip or release the liner, as the case may be. The work is held accurately in position, and takes no longer to chuck than the ordinary method, besides which, the risk of the work springing whilst being machined is greatly eliminated. The device proved highly satisfactory, and the liners were found to be turned a,ccurately concentric. When once this tool is made the decreased cost with which the work can be turned out more than compensates for the time spent in preparing it."

To Prevent the Bolt Turning.

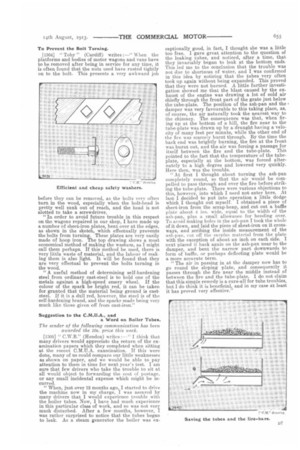

[1304] " Toby " (Cardiff) writes :—" When the platforms and bodies of motor wagons and vans have to be removed after being in service for any time, it is often found that the nuts used have rusted tightly on to the bolt. This presents a very awkward job before they can be removed, as the bolts very often turn in the wood, especially when the bolt-head is pretty well sunk out of reach, and the head is not slotted to take a, screwdriver.

"In order to avoid future trouble in this respect on the wagons repaired in our shop, I have made up a number of sheet-iron plates, bent over at the edges, as shown in the sketch, which effectually prevents the bolts from turning. These _plates are very easily made of hoop iron. The top drawing shows a most economical method of making the washers, as I might call them perhaps. If this method be used, there is very little waste of material, and the labour of making them is also light. It will be found that they are very effectual to prevent the bolts turning in the wood.

"A useful method of determining self-hardening steel from ordinary cast-steel is to hold one of the metals against a high-speed emery wheel. If the colour of the spark be bright red, it can be taken for granted that the material being ground is caststeel. If it is a dull red, however, the steel is of the self-hardening brand, and the sparks made being vary much like those given off from cast-iron."

Suggestion to the C.M.U.A., and a Word on Boiler Tubes.

The sender of the lollowing communication has been awarded the Ws. prize this week.

[1205] " C.W.B." (Hendon) writes : —" I think that many drivers would appreciate the return of the examination papers which they completed when sitting at the recent C.M.U.A. examination. If this were done, many of us could compare our little weaknesses as shown on paper, and we would be able to pay attention to them in time for next year's test. I am sure that few drivers who take the trouble to sit at all would object to forwarding the cost of ipostage, or any small incidental expense which might be incurred.

"When, just over 12 months ago, I started to drive the machine now in my charge, I was assured by many drivers that I would experience trouble with the boiler tubes. Now, I have had much experience in this particular class of work, and so was not very much disturbed. After a few months, however, I was rather surprised to notice that the tubes began to leak. As a steam generator the boiler was ex ceptionally good, in. fact, I thought she was a little too free. I gave great attention to the question of the leaking tubes, and noticed, after a time, that they invariably began to leak at the bottom ends. This led me to the conclusion that the trouble was not due to shortness of water, and I was confirmed in this idea by noticing that the tubes very often took up again without being expanded. This proved that they were not burned. A little further investigation showed me that the blast caused by the exhaust of the engine was drawing a lot of cold air chiefly through the front part of the grate just below the tube-plate. The position of the ash-pan and the damper was very favourable to this taking place, as, of course, the air naturally took the nearest way to the chimney. The consequence was that, when firing up at the bottom of a hill, the fire near to the tube-plate was drawn up by a draught having a velocity of many feet per minute, while the other end of the fire was scarcely burnt through. By the time the back end was brightly burning, the fire at the front was burnt out, and the air was forcing a passage for itself between the fire and the tube-plate. This pointed to the fact that the temperature of the tubeplate, especially at the bottom, was forced alternately to a high degree and lowered very quickly. Here then, was the trouble. "At first I thought about turning the ash-pan completely round, so that the air would be compelled to pass through and over the fire before etrikmg the tube-plate. There were various objections to this, however, into which I need not enter here. At last I decided to put into operation a little dodge which I thought out myself. I obtained a piece of sheet-iron from the scrap-heap, and cut out a baffle plate about 4 ins, wide, equal to the width of the ash-pan, plus a small allowance for bending over. To avoid making holes in the ash-pan I took the whole of it down, and laid the piece of sheet-iron on it crossways, and scribing the inside measurement of the ash-pan, cut off the surplus material from the plate with the exception of about an inch on each side. I next placed it back again on the ash-pan near to the damper, and bent the narrow part downwards to form of baffle, or perhaps deflecting plate would be a more accurate term.

"The air in passing in at the damper now has to go round the sloping plate, and consequently it passes through the fire near the middle instead of between the fire and the tube-plate. I do not claim that this simple remedy is a cure-all for tube troubles, but I do think it is beneficial, and in my case at least it has proved very effective."