FIELD OF OPPORTUNITY

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

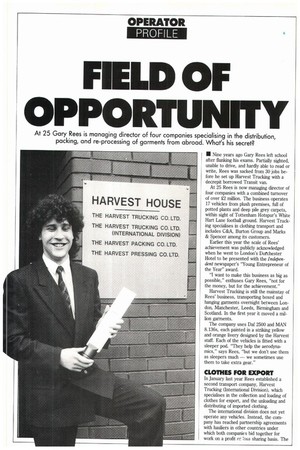

At 25 Gary Rees is managing director of four companies specialising in the distribution, packing, and re-processing of garments from abroad. What's his secret?

• Nine years ago Gary Rees left school after flunking his exams. Partially sighted, unable to drive, and hardly able to read or write, Rees was sacked from 30 jobs before he set up Harvest Trucking with a decrepit borrowed Transit van.

At 25 Rees is now managing director of four companies with a combined turnover of over 22 million. The business operates 17 vehicles from plush premises, full of potted plants and deep pile grey carpets, within sight of Tottenham Hotspur's White Hart Lane football ground. Harvest Trucking specialises in clothing transport and includes C&A, Burton Group and Marks & Spencer among its customers.

Earlier this year the scale of Rees' achievement was publicly acknowledged when he went to London's Dorchester Hotel to be presented with the Independent newspaper's "Young Entrepreneur of the Year" award.

"I want to make this business as big as possible," enthuses Gary Rees, "not for the money, but for the achievement."

Harvest Trucking is still the mainstay of Rees' business, transporting boxed and hanging garments overnight between London, Manchester, Leeds, Birmingham and Scotland. In the first year it moved a million garments.

The company uses Daf 2500 and MAN 8.136s, each painted in a striking yellow and orange livery designed by the Harvest staff. Each of the vehicles is fitted with a sleeper pod. "They help the aerodynamics," says Rees, "but we don't use them as sleepers much — we sometimes use them to take extra gear."

CLOTHES FOR EXPORT

In January last year Rees established a second transport company, Harvest Trucking (International Division), which specialises in the collection and loading of clothes for export, and the unloading and distributing of imported clothing.

The international division does not yet operate any vehicles. Instead, the company has reached partnership agreements with hauliers in other countries under which both companies bid together for work on a profit or !oss sharing basis. The international partner then deals with the transport of the goods to and from overseas while Harvest deals with the British side. Harvest's overseas partners include Mode Express from the Netherlands and Josef Mayer from Germany.

Rees expects his company itself will begin operating on the continent this summer, probably starting in France, Holland and Belgium. He plans to buy or lease trailers for international work and is also interested with trade into Cyprus — "a country with a lot of potential. The international business is growing fast," says Rees. "So far this year, turnover has increased 87%."

Rees' first business venture outside trucking came with the establishment of Harvest Packing in December 1986, which does work for mail order companies like GUS and Grattans.

"We create a lot of our own business," says Rees, "Harvest Packing is on contract to most of the big mail order companies and we pack everything from cameras, to diaries, to clothes."

The packing is done at Harvest's secure 2,700m2 warehouse premises in Tottenham. It is labour-intensive work and accounts for a fair proportion of Harvest's 100-strong staff.

Rees' latest company is Harvest Pressing, established in January this year, reprocessing garments from abroad. Harvest Pressing will "press, bag and ticket" clothes for customers. "We are trying to earn more from each garment in the chain," he says, "we are expanding around clothing but we have no plans to get into clothing manufacturing — there's not enough money in it. Nearly all our work is clothing but we will look at anything so long as it's clean."

NEW WAREHOUSE

Harvest's next development is the opening of a £750,000 warehouse in Manchester or Leeds (Rees won't say which) in September. The warehouse will reprocess and press clothes for local distribution in the north of England. "This is going to be the biggest potential growth area for us. We are going to support it with 8 to 10 40ft trailers and three tractors."

"We plan to be processing so many clothes we will be filling a trailer everry three-and-a-half hours, so we may run a double or a treble shift."

Many of the people who work with Rees are former school friends. Steve Parkin, for instance, who is now responsible for the company's operations in the north of England. When the new warehouse opens it will be Parkin's responsibility, but Gary Rees intends to, "live up there initially to set the operation up — its very important to me."

"As we grow we always try to expand our management before we expand our service," he says, "so we always have mangers in hand. As the company gets bigger it becomes much harder to keep track of profits," admits Rees, "but we have six account and clerical staff and excellent advisers."

As part of the Independent Young Entrepreneur award, Rees won £7,500 of financial advice from merchant bank Ernst Whinney. Harvest is using the advice initially in the preparation of a business plan for future development. Rees' other prizes included a 25,000 IBM computer which has still to be delivered, but which will eventually be used for accounts, warehousing, storage and vehicle costings; and 21 years' supply of Filofax. "I never use them," concedes Rees, "1 normally try to commit things to memory."

"We do have problems — but thankfully none of them have been major," he adds. "Occasionally they are because of inexperience but we learn from our mistakes. I have made a few mistakes with personnel, but I am learning more about man management every day."

"The management style here is very personal. Everybody uses first names and I don't think anyone regards me as 'the boss'. I like to get people to develop as individuals. Everyone has a lot of talent, you just have to find their initiative."

Rees wants to continue to win business from big-name companies. "We have won most of our contracts with big customers during the last year or so. Most large companies will only deal with other big companies so you have to have some kind of substance to win those kind of contracts. That's what we want, secure ongoing business. We aren't trying to grow where there is lots of competition from little companies — we go for the bigger contracts because we can offer the higher service levels."

NEIL YOUNG ALBUM

For a five-year-old company Harvest certainly looks substantial, though Rees admits, 'That's not substance financially, its more cosmetic — the nice premises, the good looking fleet." The Harvest name was chosen by Rees, who is a great fan of the Neil Young album of the same name. The 'Trucking Company' appendage was added in deference to the rock band transport specialist Edwin Shirley Trucking Company. "I like the high profile and love the glamour of the business," he says, "I would like to get into rock and roll trucking — it would be great to tour with a band."

As with many fast growing companies, Harvest has benefitted from good, understanding financial backing. "Finance is a problem for a small business but we've got a very good manager with the National Westminster Bank who is open to our suggestions. With our growth at present we're now in the process of arranging quite a lot of finance."

"Our problem is not to give the company away in terms of venture capital," says Rees. He claims he has had interested approaches from customers seeking to acquire a share of the operation. "It's not valuable enough yet," he adds, "and besides, what else can I do? I can't do anything but this."

by Richard Scrase