High Reputation Maintained in 35-cw1

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

First-class Access, Driver Considerations and Finish Are Features of Mercedes-Benz L319 D Van Now Introduced in Britain by A. J. P. Wilding

IN the introduction of Mercedes-Benz commercial vehicles to the United Kingdom market, the concessionaires—Mercedes-Benz (Great Britain), Ltd.—have the help of the high reputation that cars of the same make have earned. Part of this reputation has been built on high standards of finish, workmanship and unit design, amongst other things. Whilst the initial sales will get help from the cars' reputation, in the long run the commercial vehicles have to stand on their own.

So far as the points quoted are concerned—those on which the commercial vehicles can be compared to the cars —the Mercedes-Benz L319D van tested is able to stand on its own quite adequately, particularly in regard to finish.

This is the impression given as soon as the cab is entered, for, although the outward frontal appearance may not be to everyone's taste, the cab (which on the hinged-door version tested is separated from the body by a full-height bulkhead) will find few if any critics. It is most unlikely that any driver of this van will have cause for complaints of any degree at the consideration given him.

Access to the cab is good and in all respects driving the L319D is free from strain. The steering is light and direct; the pistol-grip handbrake and all controls are within easy reach; the clutch is light and the brake' pedal not elf) unduly heavy; and the steering-column gear change to the synchromesh gearbox cannot be faulted.

Most important of all to some people is that part of the standard equipment is a very effi-. cient and powerful heater and demister unit. Warm air can be directed to the driver's side. the passenger's side or the windscreen, or combinations of the three by pull-out controls on the right-hand side of the dash. A twospeed fan can be brought into action if required through a switch on the instrument panel.

This is, incidentally, a most comprehensive affair and, in addition, to the speedometer. water temperature gauge and light switch, contains four large warning lights (main beam, direction indicators, oil pressure and battery charging), a combined glow plug, starter and engine stop switch; a manual engine slowrunning control, and a number of switches for various units such as wipers and panel light.

Flashing direction indicators which are fitted as standard are operated by rotating the horn ring which is located at the centre of the steering wheel. Although the indicators are not self-cancelling and I often sounded the horn when making a signal, after I had got used to the arrangement I found no difficulty.

Cab ventilation is provided by hinged door quarter lights, which act as air scoons, and sliding cab-door windowS.

The 1.8-litre, four-cylindered engine fitted to the L319D is virtually identical to the unit in the oil-engined version of the Mercedes-Benz 180 passenger car. It is mounted. together with the gearbox, radiator, front axle and springs, telescopic dampers and steering gear on a sub-frame, which is rubber-mounted to the underside of the main chassis frame. This allows the complete assembly to be removed when major overhaul is required.

Rear suspension of the L319D is through fairly long, semi-elliptic leaf springs with additional coil springs mounted on brackets at the rear of the axle, the top faces being fitted to the underside of the frame. Telescopic dampers are also fitted. The ride given by the suspension layout is excellent over all types of road surface and there is good stability when cornering.

The general standard of construction and finish of the all-metal body is first class. A timber floor is fitted and steel straps riveted to the vertical body framework besides giving added strength can also be usefully employed for load fixing.

It is, perhaps, hoping too much that the matching of such a small engine to a vehicle weighing almost 31 tons fully laden will give a spark ling performance. The power/weight ratio of 0.58 b.h.p. per cwt. of gross weight is. in fact, comparatively low for this size of van, and although performance could not he described as sluggiSh speed is affected more than is usual on even slight gradients. This was most. noticeable in top gear, particularly when approaching maxim u m speed—in intermediate gears acceleration was quite commendable.

I would imagine that the main reason for the poor top gear performance is that the designers have tried to please too many people at once in providing a relatively high maximum speed of 55 m.p.h. and, at the same time, good hill-climbing ability---a gradient of 1-in-4.I is given in the specification as being within the capabilities of the van.

Widely Spaced Gear Ratios The maximum speeds attained in the four gears —8, 17. 31 and 55 m.p.h.– confirmed this and I feel that alternative rear axle ratios in conjunction with closer gearbox ratios would be a better proposition. If this were the case, gearbox and axle ratios could be such that when a van wa,.; required to climb gradients of 1-in-4, maximum gear speed; could be 8. 15, 25, 40 m.p.h, and if, on the other hand. a maximum speed of 55 m.p.h. were more desirable and the maximum gradient encountered no more than 1-in-6. maximum gear speeds could be around 13, 24, 38, 55 m.p.h. With both arrangements general performance would, in my opinion, be more acceptable and the overtaking of vehicles travelliniz around 30 m.p.h, would be made easier.

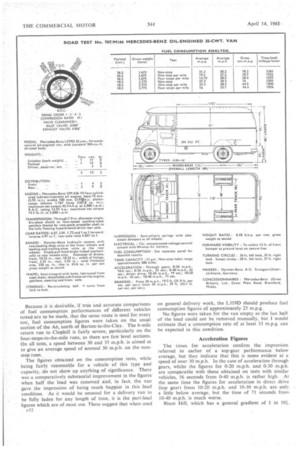

Because it is desirable, if true and accurate comparisons of fuel consumption performances of different vehicles tested are to be made, that the same route is used for every test, fuel consumption figures were taken on the usual section of the A6, north of Barton-in-the-Clay. The 6-mile return run to Clophill is fairly severe, particularly on the four-stops-to-the-mile runs, as there are few level sections. On al tests, a speed between 30 and 35 m.p.h. is aimed at to give an average speed of around 30 m.p.h. on the nonstop runs.

The figures obtained on the consumption tests, while being fairly reasonable for a vehicle of this type and capacity, do not show up anything of significance. There was a comparatively substantial improvement in the figures when half the load was removed and, in fact, the van gave the impression of being much happier in this load condition. As it would be unusual for a delivery van to be fully laden for any length of time, it is the part-load figures which are of most use. These suggest that when used c12 on general delivery work, the L319D should produce fuel consumption figures of approximately 25 m.p.g.

No figures were taken for the van empty as the last half of the load could not be removed manually, but I would estimate that a consumption rate of at least 33 m.p.g. can be expected in this condition.

Acceleration Figures The times for acceleration confirm the impression referred to earlier of a top-gear performance below average, but they indicate that this is more evident at a speed of over 30 m.p.h. In the case of acceleration through gears, whilst the figures for 0-20 m.p.h. and 0-30 m.p.h. are comparable with those obtained on tests with similar vehicles, 56 seconds from 0-40 m.p.h. is rather high. At the same time the figures for acceleration in direct drive (top gear) from 10-20 m.p.h. and 10-30 m.p.h. are only a little below average, but the time of 71 seconds from 10-40 m.p.h. is much worse.

Bison Hill, which has a general gradient of 1 in 10!.. was used for the hill performance tests. In these, the L319D gave a reasonably good performance by completing a fast, full-power ascent in 3 minutes 51 seconds. First gear was necessary for 1 minute 26 seconds of the time and the minimum speed during the climb was 8 m.p.h.

On the steepest section, which is a 1-in-6i gradient, the van just failed to start off in.2nd gear, but took off comfortably in bottom. I would agree with the claim in the specification that a 1-in-4.1 gradient could be climbed.

Brake-fade Assessed

In order to assess the brake-fade characteristics of the van, the descent of the hill was made in neutral, with the foot-brakes applied to keep the speed down to 20 m.p.h. On the final stretch of the hill, the gradient flattens out and here top gear was engaged and full throttle applied to keep the speed at 20 m.p.h. with the brakes still on. Total time taken for the descent was 2 minutes 30 seconds with 37 seconds spent in top gear. At the end of the run, a crash-stop from 20 m.p.h. produced a Tapley-meter reading of 68 per cent. compared with the reading of 85 per cent obtained later with cold drums. As there was no increase in pedal movement the relatively small amount of fade was caused by brake-linings' efficiency drop. Braking tests were carried out last, the road surface being dry asphalt with stone chippirtgs. Stopping distances of 19 ft. 6 in. from 20 m.p.h. and 39 ft, from 30 m.p.h. were obtained, which is quite commendable for this type of vehicle. What is more important is that under crashstop conditions the L319D was perfectly stable and there was a very good balance between front and rear brakes. A Tapley-meter reading of 34 per cent. was obtained for he hand-brake, which is fairly good.

Comprehensive Tool Kit

Fears that maintenance will be complicated by metric size bolt-heads will be allayed when the comprehensive kit of good-quality tools is seen. 'Apart from open-ended spanners for sizes from 9 mm. to 19 mm., the standard kit includes two box spanners, a screwdriver set, an adjustable wrench and two strong tyre levers.

Routine or driver maintenance on the L319D is fairly straightforward. Water and engine-oil levels can be checked after removing the engine front cover. Time taken for an oil level check was 35 seconds, of which 8 seconds was to remove and 12 seconds to refit the front cover. The oil-bath air-cleaner element is also reached from the front and total time to check the oil level in this unit was 1 minute 3 seconds, which included removing and refitting the front cover.

The levels of rear-axle oil and that of fluid in the brake reservoir (accessible through a plate in the cab floor on the driver's side) were both checked easily, in 1 minute 7 seconds, and 1 minute 1 second respectively. On the other hand, a battery-electrolyte-level check took 2 minutes 17 seconds, because of the battery being located underneath the driver's seat, and it being difficult to reach the filler caps. It was impossible to see the level without removing the seat completely and this would have been a lengthy job.

It also took longer than expected to check the level of gearbox oil—it took me 4 minutes 37 seconds. This was because the positions of hand-brake rod and speedometer cable made it difficult to remove the level plug. On the more usual left-hand-drive version, these would be on the other side of the gearbox.

Injector-change Complex I intended timing the changing of an injector, but as this was not as straightforward as I had hoped, due to the dribble pipe arrangement being fairly complex, I abandoned this idea. However. I would estimate the time for changing

a set of injectors at hours.

The final task carried out was the adjusting of the brakes at one wheel. An excellent hydraulic jack is supplied in the tool kit and this helped considerably in making the total time for this job 3 minutes 5 seconds.