Oil Fuel :

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

The Careful Storage and Dispensing of Oil Fuel are Safeguards Against Premature Failure of Injection Equipment WHILST the oil companies take every possible precaution to prevent their products becoming contaminated with foreign matter, the same cannot be said of some operators. Although cleanliness is of first importance in the storage of oils, greases and petrol, the result of neglect where oil fuel for compression-ignition engines is concerned, may prove extremely costly.

When dirty petrol gets through to the float chamber of a carburetter the chances are that the contaminating matter will fall to the bottom and remain inert, but in the case of dirty oil filel reaching the injection pump, there is a distinct possibility of serious damage being caused to the finely finished plungers and valves.

In theory it should not be possible for dirty fuel to reach the injection pump, but no matter what efficiency claims may be made for line filters, the fact remains that the abrasive effect of the indescribably fine particles of dust which pass over with the fuel, causes many injectionequipment failures.

For this reason, it is obviously good. practice to relieve the 'filtersof as Much responsibility as possible. The

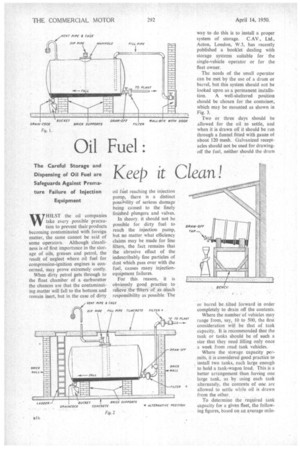

way to do this is to install a proper system of storage. C.AV., Ltd., Acton, London, W.3, has recently published a booklet dealing with storage systems suitable for the single-vehicle operator or for the fleet owner.

The needs of the small operator can be met by the use of a drum or barrel, but this system should not be looked -upon as a permanent installation. A well-sheltered position should be chosen for the container, which may be mounted as shown in Fig. 3.

Two or three days should be allowed for the oil to settle, and when it is drawn off it should be run through a funnel fitted with gauze of about 120 mesh. Galvanized receptacles should not be used for drawingoff the fuel, neither should the drum or barrel be tilted forward in order completely to drain off the contents.

Where the number of vehicles may range from, say, 10 to 500, the first consideration will be that of tank capacity. It is recommended that the tank or tanks should be of such a size that they need filling only once a week from road tank vehicles.

Where the storage capacity permits, it is considered good practice to install two tanks, each large enough to hold a tank-wagon load. This is a better arrangement than having one large tank, as by using each tank alternately, the contents of one are allowed to settle while oil is drawn from the other.

To determine the required tank capacity for a given fleet, the following figures, based on an average mile age of 200 per week and an average of 10 m.p.g., should be useful.

A point to be remembered in connection with the storage of oil fuel is that it is not subject to the same strict regulations as those governing the storage of petrol. The operator thus has greater freedom in choosing the storage site. The fuel may be stored above or below ground, or in the garage or in the open air.

Fig. I shows an above-ground installation, which has advantages over an underground system in lower cost and ease of access for servicing and cleaning. Whilst, for convenience of drawing off fuel, the tank should be raised, it is to be noted that the maximum height above the level of the vehicle to which road tank wagons can discharge their load is 30 ft.

Underground installations (Fig. 2) . have One important advantage, in that • the space above the tank or tanks can be used, but otherwise it would seem that the above-ground storage system has much to commend it. Tanks should not be buried in the, earth, • but should be installed in a properly built pit sufficiently large to .make the tank accessible at all points.

It will be a help to give the dimensions and . capacities of the tanks available from, the leading makers. These are as follows:—

generally recommended. It should be made of steel, and whilst it may be galvanized on the outside, in no circumstances should an oil-Fuel tank, or the pipes connected to it. be galvanized on the inside. If the exterior be not galvanized, it should be given at least two coats of bituminous paint.

Cleanliness of the interior cannot be unduly stressed, and a new tank should be cleaned of all scale and rust before installation. When petrolstorage tanks are to be changed over to oil fuel, the greatest care must be taken to see that they are scrupulously clean before the oil fuel is introduced.

Tank supports will usually be of brick or concrete, and designed to give a backward tilt to the tank of in. to i in. per foot of length. This is shown in Figs. 1 and 2.

A little extra care taken in the storage and dispensing of oil fuel may make a big difference in vehicle availability over a period of months.

The illustrations are reproduced by the courtesy of C.A.V., Ltd.