The Latest

Page 58

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

A.E.C. ACTIVITIES

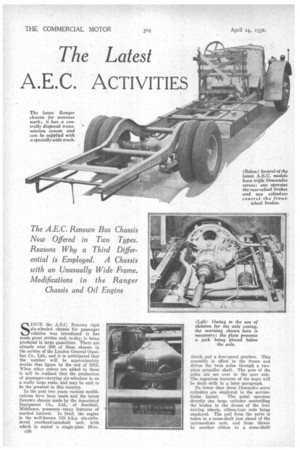

The A.E.C. Renown Bus Chassis Now Offered in Two Types. Reasons Why a Third Differential is Employed. A Chassis with an Unusually Wide Frame. Modifications in the Ranger Chassis and Oil Engine

'SINCE the A.E.C. Renown rigid six-wheeled chassis for passenger vehicles was introduced it has made great strides and, to-day, is being produced in large quantities. There are already over 500 of these chassis in the service of the London General Omnibus Co., Ltd., and it is anticipated that the number will he approximately double that figure by the end of 1931. When other orders are added to these it will be realized that the production of passenger-carrying six-wheelers is on a really large scale, and may be said to be the greatest in this country.

In the past two years various modifications have been made and the latest Renown chassis made by the Associated Equipment Co., Ltd., of Southall, Middlesex, possesses many features of marked interest. In brief, the engine is the well-known 110 b.h.p. six-cylindered overhead-camshaft unit, with which is mated a single-plate 16-in c36 clutch and a four-speed gearbox. This assembly is offset in the frame and drives the twin axles through a twopiece propeller shaft. The pots of the axles are set over to the near side. The ingenious features of the bogie will be dealt with in a later paragraph.

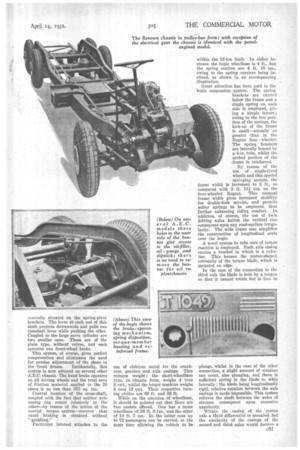

No fewer than three Dewandre servo cylinders are employed in the service brake layout. The pedal operates oirectly one large cylinder controlling the brakes in the drums of the four driving wheels, ribbon-type rods being employed. The pull from the servo is taken to a cross-shaft just ahead of the intermediate axle, and from thence by another ribbon to a cross-shaft centrally situated on the spring-pivot brackets. The lever at each end of this shaft projects downwards and pulls one camshaft lever while pushing the other. Coupled to the large servo cylinder are two smaller ones. These are of the plain type, without valves, and each operates one front-wheel brake.

This system, of course, gives perfect compensation and eliminates the need for precise adjustment of the shoes in the front drums. Incidentally, this system is now adopted on several other A.E.C. chassis. The hand brake operates on all driving wheels and the total area of friction material applied to the 20 shoes is no less than 875 sq. ins.

Central location of the cross-shaft, coupled with the fact that neither axle casing can rotate relatively to the other—by reason of the action of the special torque system—ensures that equal braking is obtained without "grabbing." Particular interest attaches to the use of elektron metal for the crankcase, gearbox and axle casings. This reduces weight; the short-wheelbase type, in chassis form, weighs 4 tons 8 cwt., whilst the longer machine weighs 4 tons 12 cwt. Their respective turning circles are 60 ft. and 06 ft.

While on the question of wheelbase, it should be pointed out that there are two models offered. One has a mean wheelbase •of 16 ft. 6 ins., and the other of •18 ft. 7 ins: In the latter case up to 72 passengers can be carried, at the same time allowing the vehicle to be

within the 12-ton limit. In either instance the bogie wheelbase is 4 ft., but the spring centres are 4 ft. 10 ins., owing to the spring carriers being inclined, as shown in an accompanying illustration.

Great attention has been paid to the bogie suspension system. The spring brackets are carried below the frame and a single spring on each side is employed, giving a simple layout; owing to the low position of the springs, the kick-up of the frame is small—actually no greater than in the Regent four wheeler. The spring brackets are laterally braced by a. 4-in, tube, whilst the arched portion of the .frame is reinforced.

By reason of the use of single-tyred wheels and this special springing system, the frame width is increased to 5 ft., as compared with 3 ft. 11i ins, on the four-wheeled Regent. This unusual frame width gives increased stability for double-deck service, and permits softer springs to be employed, thus further enhancing riding comfort. In addition, of course, the use of twin driving axles halves the vertical rise consequent upon any road-surface irregularity. The wide frame also simplifies the construction of longitudinal seats over the bogie.

A novel system to take care of torque reaction is employed. Each axle casing carries a bracket in which is a cylinder. This houses the piston-shaped extremity of the torque blade, which is mounted on edge.

In the case of the connection to the third axle the blade is held by a tongue so that it cannot rotate but is free to plunge, whilst in the case of the other connection, a slight amount of rotation can occur, also plunging, and there is sufficient spring in the blade to whip laterally ; the blade being longitudinally rigid, relative rotation between the axle casings is made impossible. This system relieves the shaft between the axles of stresses consequent upon excessive angularity.

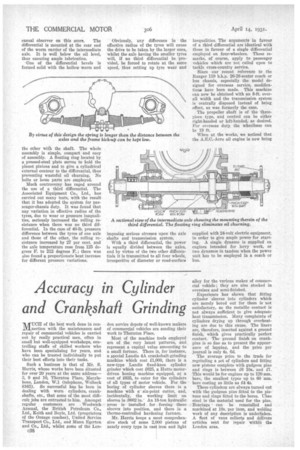

Within the rasing of the centre axle a third differential is mounted, but the similarity of the casings of the second and third axles would deceive.a casual observer on this score. The differential is mounted at the rear end of the worm carrier of the intermediate axle. It is well below the oil level, thus ensuring ample lubrication.

-One of the differential bevels is formed solid with the hollow worm and the other with the shaft The whole assembly is simple, compact and easy of assembly. A floating ring located by a pressed-steel plate serves to hold the planet pinions and to give a cylindrical external contour to the differential, thus preventing wasteful oil churning. No bolts or loose parts are employed.

Much controversy has raged around the use of a third differential. The Associated Equipment Co., Ltd., has carried out many tests, with the result that it has adopted the system for passenger-chassis duty. It was found that any variation in effective radius of the tyres, due to wear or pressure inequalities, seriously increased the rolling resistance when there was no third differential. In the case of 40-lb. pressure difference between the tyres of one axle and those of the other, the rolling resistance increased by 27 per cent, and the axle temperature rose from 125 degrees E. to 212 degrees F.; there was also found a proportionate heat increase for different pressure variations. • Obviously, any difference in the effective radius of the tyres will cause the drive to be taken by the larger ones, whilst the axle having the smaller tyres will, if no third differential be provided, be forced to rotate at the same speed, thug setting up tyre wear and imposing serious stresses upon the axle shafts and transmission system.

With a third differential, the power is equally divided between the axles, and by virtue of the two other differentials it is transmitted to all four wheels, irrespective of diameter or road-surface

inequalities. The arguments in favour of a third differential are identical with those in favour of a single differential employed on four-wheelers. These remarks, of course, apply to passenger vehicles which are not called upon to tackle cross-country service.

Since our recent reference to the Ranger 110 le.h.p. 26-28-seater coach or bus chassis, especially the model designed for overseas service, modification have been made. This machine can now be obtained with an S-ft. overall width and the transmission system is centrally disposed instead of being offset, as was formerly the case.

The propeller shaft is of the threepiece type, and control can be either right-handed or left-handed, as desired. For overseas duty the wheelbase can be 19 ft.

When at the works, we noticed that the A.E.0.-Acro oil engine is now being supplied with 24-volt electric equipment, in order to give ample power for starting. A single dynamo is supplied on engines intended for lorry work, or two dynamos in tandem when the power unit has to be employed in a coach or bus.