ONE OF THE MAN)"

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

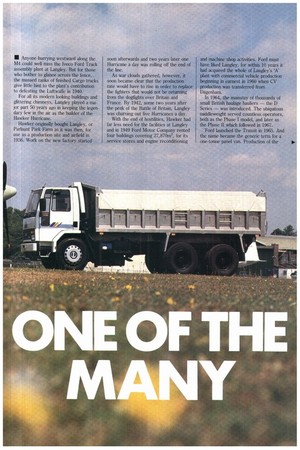

• Anyone-hurrying westward along the M4 could well miss the lveco Ford Truck assembly plant at Langley. But for those who bother to glance across the fence, the massed ranks of finished Cargo trucks give little hint to the plant's contribution to defeating the Luftwaffe in 1940.

For all its modern looking buildings and glittering chimneys, Langley played a major part 50 years ago in keeping the legendary few in the air as the builder of the Hawker Hurricane.

Hawker originally bought Langley, or Partaunt Park Farm as it was then, for use as a production site and airfield in 1936. Work on the new factory started soon afterwards and two years later one Hurricane a day was rolling off the end of the line.

As war clouds gathered, however, it soon became clear that the production rate would have to rise in order to replace the fighters that would not be returning from the dogfights over Britain and France. By 1942, some two years after the peak of the Battle of Britain, Langley was churning out five Hurricanes a day.

With the end of hostilities, Hawker had far less need for the facilities at Langley and in 1949 Ford Motor Company rented four buildings covering 27,870m2, for its service stores and engine reconditioning

and machine shop activities. Ford must have liked Langley, for within 10 years it had acquired the whole of Langley's 'A' plant with commercial vehicle production beginning in earnest in 1960 when CV production was transferred from Dagenham.

In 1964, the mainstay of thousands of small British haulage hauliers — the D Series — was introduced. The ubiquitous middleweight served countless operators, both as the Phase I model, and later as the Phase II which followed in 1967.

Ford launched the Transit in 1965. And the name became the generic term for a one-tonne panel van. Production of the Transit continued at Langley for seven years until 1972, when it was tranferrred to its current home at Ford's Southampton plant.

A year later the ill-fated A Series was introduced. Intended to boost Ford's CV sales in the elusive market between 3.5 and 7.5 tonnes, the A Series never won the hearts of operators, especially when starting it on a cold morning.

In 1977 Ford bought the Firestone site next door to Langley which was eventually refurbished and put to work as the plant's main storage and goods-inwards reception.

The late seventies was a period of consolidation at Langley as trim and cab assembly and paint work was also brought into the plant from Southampton.

But the most significant phase in the plant's history was the arrival of the Cargo, the successor to the old D Series in 1981. By any yardstick the Cargo was truly a modern truck, and that meant building it using modern techniques. So the new body construction area was equipped with robots.

With the launch of the Cargo, Ford continued to upgrade Langley with flush-floor conveyors and computerised rolling-road and brake-test equipment. By 1983 the A Series was finally phased out as the sleeper-cab Cargo came on stream.

In 1985 the plant celebrated one of many milestones with the anniversary of 25 years of truck building at Langley. Few people at the plant would hve guessed that within a year Ford would tie up with Iveco to form Iveco Ford Truck, the company that enjoys the benefits of the Cargo today. Over the past four years the changes have continued at Langley. They include the advent of the Rockwell rear axle programme and the introduction of disc brakes on Cargo models between six to eight tonnes.

In 1988 the 100,000th Cargo was built. Since then IFT has opened a training centre on the site and from 1989 Langley has enjoyed the fruits of an investment programme of £17.7m which has seen production facilities improved to accommodate the long-awaited Cargo replacement. Today the plant covers 26ha and employs 1,450 people.

Not bad for Partaunt Park Farm and an old aeroplane factory.

by Brian Weatherley