We said

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 12

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

"Ask the men who buy them"

This was the brief given to John DicksonSimpson of Transport Press Services at a meeting in Oldham, Lancashire, earlier this year.

Seddon Motors Ltd. had decided to commission an extensive survey of their customers. To ensure the validity of the survey it was to be entrusted to an independent authority in transport matters. The choice fell upon John Dickson-Simpson, well known as a journalist in the transport press and now manager of an independent consultancy. He was asked to visit Seddon users in whichever areas he chose. to question and talk freely with them on every aspect of operation—reliability, running costs. comparisons with other makes of vehicle

owned, 'relations with the factory • He was given carte blanche to report both praise and complaint, both enthusiasm and any disappointments.

His full report, a 48 page document, is in the hands of the Seddon Board. In the pages which follow we present verbatim extracts which highlight current road transport problems in varied fields of operation. In many cases it is shown how the choice of Seddon s has helped to ease them.

We believe that this is the first time that such a survey has been published by a manufacturer. For this and other reasons we are sure you will find it interesting.

Ask any haulier what he means by "Good" when talking about "a good wagon" and he will explain that he means "reliable". Judging by my interviews with hauliers up and down the country it is reliability which is accounting for the description "a good wagon" when they talk about Seddons. This seems equally true of both light and heavy models. The combination of well-tried engine-transmission units in a thoroughbred chassis, including its axles, seems to be well liked and the attractive prices which result are ensuring that few operators ignore Seddons when determining buying policies.

As Mr. E. Wilkinson, boss of the Wilkinson Transport group. Rochdale, told me: -It was a bold decision of Seddons to introduce that 13:Four model and take on the mass producers. They deserve to be supported." As a smalls carrier, he likes the element of versatility in the 13:Four Seddon. It is not an ideal parcels delivery vehicle if you were designing for that specific duty, but the cab entrance is convenient enough to be tolerable for such work on a part-time basis. So the Seddons are used primarily for trunking between depots, but they also help out with parcels collection—and delivery during the day. So the Wilkinson Seddons do not get much rest: they clock up about 70,000 miles a year. This will be even more when a swop-body system has been fully introduced.

Beating the post

Another smalls operator, Plackett's Transporter Ltd., Nottingham, uses 13:Fours on both delivery and trunk. "We can beat the post in many cases", is the proud claim of the transport director, Mr. Paul Wright. It was decided to standardise on the Seddons after the good record of reliability put up by a few runs experimentally against other makes including one from Germany and because its specification seemed to offer the best compromise after the tables of specifications published in the "Commercial Motor" had been studied in depth. An important point in favour of the Seddons was their tight lock.

Apart from standing between 10 p.m. and 3 a.m. the vans are on the move all the time and they cover between 50,000 and 60,000 miles a year. Routine maintenance is done at night on a fortnightly interval basis. The vans have 50-gallon fuel tanks so that they can make a round trip without refuelling.

Replacements of vehicles are supposed to be made every five years but since Seddons became the standard vehicle and since they have been equipped with aluminium-alloy bodies by a bodybuilder in Nottingham, Reg Watson & Co., the replacement period has been extended to six years, during which a vehicle usually does about 250,000 miles: After four years operation the chassis is overhauled and it then spends its remaining two years on B-licence short-distance work. Replacement is principally determined by the appearance of the cab and bodywork.

Costs favour Seddons

At Smith's of Eccles Ltd., the work is mainly long-distance: Both rigid and articulated versions of the 13:Four are run. All of them are specified with two-speed axles. Fuel consumption of the Perkins-engined Seddons averages 10.4 m.p.g. on the 16-ton gross four-wheelers and 12.5 m.p.g. on the 14-ton gross 13:Fours. This is not as good as more expensive vehicles powered by Gardner 4LW and 5LW engines. for which a fuel consumption of 14 m.p.g. is usual. Nevertheless, taking account of the fact that the Seddons are cheaper in the first place, the overall economics favour the Seddons, Mr. George Gregory, the fleet engineer, told me.

The snag with their long depreciation periods of expensive machines is that vehicles can become obsolescent in the fast-changing environment of road transport these days. Furthermore, companies are tending to become very large (Smith's of Eccles is itself part of the Transport Development Group) and this means that large differences in initial cost do have a profound effect on earning power because the budget for spending money on new vehicles each year is limited and if it is possible to buy twenty Seddons instead of fifteen expensive vehicles there is the attraction that the extra number of Seddons can produce extra earning power which would otherwise be missed.

Quotes from Smith's drivers on the credits side include "the steering is lovely-Hust like a car"; -the Seddons have the best braking system there is, I think": "the wipers are good and powerful with motors that won't stall" and "they will knock-on well if you use the transmission intelligently" There were no complaints about lack of power on the four wheelers, even at 16-tons gross, although there were a few moans on this score when it came to 20-ton articulated outfits. One driver with a 16-ton Seddon was full of praise for the power-assisted steering which "takes out all the tiring work".

From the management point of view the light weight of the Seddons without spoiling structural reliability is valuable. The tractors have a weight of only 3 tons 5 cwt. and even the 16-ton gross Seddons tare at only 4 tons 141 cwt. with an aluminium body made by F.D. (Coachbuilders) of St. Helens. They like the "sensible" 50-gal. fuel tank for longdistance work.

Tried them all

There seemed to be plenty of praise for the 13:Four model in 'Scotland as well. Mr. J. Maclachlan, fleet engineer of J. and R. Wright Ltd., which now has a fleet of over 200 vehicles at Glasgow. said. "We've tried everything, and the Perkins 6.354 is the best allround engine for us. On a value-for-money basis, it's as good as a Gardner." Quite different engines, of course, but 1 think I know what he means. -Seddons are doing very well for us", he went on, "and we'll be buying more and more of them. In five years of running 6.354 engines (we've 70) I've replaced only one engine—and that was because the driver let it run short of oil."

Short-distance work predominates at Wright's. They are therefore quite rough on transmissions and brakes. Even so, they manage to get between 60,000 and 70,000 miles out of Seddon clutches and 50,000 out of brake linings. Mr. Maclachlan said that the only job outside normal maintenance had been some tightening of front spring hanger brackets ("I see they've got more bolts on the new ones"). "I want to get some Eagles now-, he says.

Eagles for B .R .S .

A big operator who has already had some Eagle-engined 32 :Fours is British Road Services.

The Rolls-Royce Eagle has been found to compare well with the other engines in its class, as far as reliability is concerned. The Eagle which was originally tried was first rated at 200 BHP, but this was found to be not good enough and was not giving such a good fuel return. But after the power was raised to 220 BHP S.A.E. the fuel consumption improved.

Over the first six months of operation, including four months at the 200 HP setting, the first Seddon Eagle has averaged 6.9 mpg. The latest fuel consumption is better than that obtained from most other machines of comparable power. The first Eagle has now done over 100.000 miles and its performance has been good.

Chassis weight is something which needs watching, because the important need is to be able to carry a 20 ton load within 30 tons gross. As some of the latest multi-purposed decked skeletal trailers weigh 4.3 tons, this leaves only 5.7 tons allowance for the tractor unit. The Seddons are within this weight at the moment. You might think that short-distance work delivering containers, mainly within a fairly tight radius, would be easy for heavy vehicles more usually engaged in fast long-distance work. But this is not the case. All sorts of special problems crop up—and it makes sense when you stop to consider the cut and thrust of congested urban roads, the continual gear changing. frequent reverse gear shunting and numerous trailer changes.

It was soon found at British Rail that fifth-wheel mountings which had been satisfactory for other types of operation could not withstand the jolting of high-intensity trailer exchange. Loosening of coupling mounting bolts and cracking of sub-frames soon became evident. But better designs were encouraged by British Rail and they made it official policy to fit fifth-wheels with cushioned mountings to absorb the shocks of coupling.

Mr. D. Hill, British Rail's Road Services Engineer, told me that they also discovered that there were often different qualities of couplings available from manufacturers, the selection depending on the price which the operator was prepared to pay. Often, it was the cheapest model which the coupling manufacturer pushed whereas a higher quality product was really required for intensive use. On none of the couplings has there been trouble with the jaws themselves. The problems have been in mountings and in plate construction.

The next problem which was met was a complaint of high decks, which proved awkward at many loading points. The first stage was to lower the trailers on their bogies so that the tail was brought to a more convenient height, but this next brought a complaint that sometimes, when the container doors were opened, goods tended to roll out. So British Rail had to find ways of lowering the front end of the trailer as well to bring the whole deck level and yet lower than before. This was done by having the fifth-wheel coupling on the tractor mounted lower than the S.M.M.T. standard. Using steel rear wings, instead of the rubber wings which are the usual British Rail practice, helped in getting the coupling as low as possible because the steel mudguards could be mounted with greater precision. Another aid to reducing the height of the front end of the trailer was to reduce the depth of the neck of the trailer frame.

Steering and transmission are two items which came in for rough usage on the shortdistance work which abounds in British Rail's operation.

So far the British Rail Seddons have had A.E.C. engine, clutch and gearbox units and at the moment there is no likelihood of this specification being altered. These Seddons give a good performance, say the British Rail drivers, and can keep up with more powerful machines. The A.E.C. is a lively engine and the gear ratios are well chosen. Moreover, the

3ear-change is quite swift. Acceleration and -011-climbing performance is more important :han maximum speed as for as British Rail is 3oncerned.

Towards automatics For the future, British Rail is looking for automatic or semi-automatic transmission although it thinks the premium being added to chassis price is so high that it makes any operator think twice before adopting more refined transmission. Mr. Hill thinks it is perfectly feasible to devise semi-automatic control for a normal clutch and gearbox arrangement, using a synchromesh gearbox of conventional twin-shaft layout which would have a considerable price lead over an epicyclic gearbox. Heavy vehicles used in quantity were a new venture for British Rail when they bought vehicles to serve.the Freightliner rail-container system. British Rail has sometimes been criticised for expanding its heavy haulage fleet at all, but the railway chiefs point out that when the Freightliner system began no one was prepared to invest in the equipment needed to handle the containers properly. When Freightliners began. not many people seemed to think that they would be the success that they have subsequently proved to be.

Now a vast expansion scheme is under way. the liner trains are overflowing with work and even British Rail's own sundries division cannot get enough liner-train capacity. So a major Stage-Two of the Freightliner scheme has now started. It will inevitably mean more road vehicles.

The general British Rail policy is not to run its own vehicles beyond a relatively restricted radius from Freightliner centres, but there are cases in sparsely populated areas such as occur in Scotland. where fairly long hauls are undertaken by British Rail when there is sufficient custom to justify it.

At the moment there are, in British Rail's fleet of Seddons, 96 24-ton gross tractors, 136 30-tonners and 129 32-tonners. There are also six 13 Four 18-ton gross tractor units.

First cost counts for a lot in British Rail's books and it is on this score that the Seddons are very attractive. Their comparatively low weight is also useful on container work.

'Most profitable'

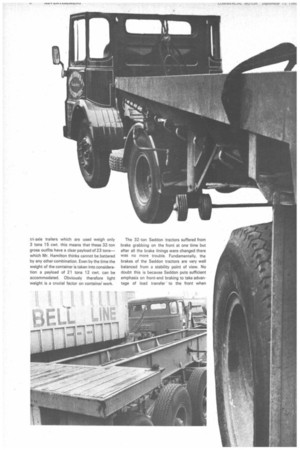

Cost and weight are also important factors as far as a Tees-side haulier intimately connected with container work is concerned; this is Henry Peacock Ltd., at Stockton-on-Tees, which has a container-hauling contract with Bell Line.

At Henry Peacock Ltd., they have decided to standardise on Seddons simply because in the words of Mr. Arthur Hamilton. the managing director, "They make the most profit for us". His enthusiasm is greatest for the Gardner-engined 30:Four.6LXB tractors which, with 180 h. p. 6LXB engines, are doing so well that he says he would not want to change them. Indeed, he thinks that he could not afford to change the specification. They do 10 m.p.g. whereas rival tractors at the same weights do 7 m.p.g. What is more, these engines have needed no attention whatsoever.

Apart from reliability and fuel economy another big attraction of these Seddon tractors from his point of view is their light weight. They have a licensing weight of only 5 tons and even the wet weight does not exceed 5 tons 5 cwt. As the skeletal Baden tri-axle trailers which are used weigh only 3 tons 15 cwt. this means that these 32-ton gross outfits have a clear payload of 23 tons— which Mr. Hamilton thinks cannot be bettered by any other combination. Even by the time the weight of the container is taken into consideration a payload of 21 tons 12 cwt. can be accommodated. Obviously therefore light weight is a crucial factor on container work. The 32-ton Seddon tractors suffered from brake grabbing an the front at one time but after all the brake linings were changed there was no more trouble Fundamentally, the brakes of the Seddon tractors are very well balanced from a stability point of view. No doubt this is because Seddon puts sufficient emphasis on front-end braking to take advantage of load transfer to the front when stopping. The braking distribution is so effective in the experience of Henry Peacock Ltd. that there has been no need for a loadsensing valve. There seems to be some indication that this experience is reliable because of two tractors of another make in the fleet, one is equipped with load-sensing and has never suffered a jack-knife either whereas anOther one does not have load-sensing and has suffered two jack-knives in the space of a year.

With the 180 h.p. engine a six-speed gearbox is adequate with the single-speed axle ("our drivers can't remember when they last hit bottom gear"). The maximum speed is 48 m.p.h. and this is considered to be quite sufficient.

Gluttons for work The 13 Four tractors are liked as well. There is a place in the fleet for 20-ton gross outfits for loads which are bulky rather than heavy. Unlike some of the other operators. Mr. Hamilton considers that this tractor is always on top of its work and that the 6.354 is a superb machine. "They like being worked hard", he says.

The stable-temperature conditions of such intensive operation certainly must be conducive to long life because he claims that the Perkins 6.354 engine will give around 180,000 miles life in his experience. They have re-ringed one or two engines but even this is not often done. When the engine is worn it is more convenient just to change the engine which costs only £190. The fuel consumption of the 13:Four tractors averages 11.5 m.p.g.

Mr. Hamilton has five 32-ton articulated vehicles working on contract for Bell Line, and he is the chairman of a consortium of hauliers on Tees-side carrying containers for Bell Line. This is a growing business and Henry Peacock Ltd. is right in on the ground flour.

The Bell Line terminal on Tees-side is so highly mechanised now that one man operating the gantry crane can unload 80 containers from a ship and load another 80 containers in the time interval between one tide and the next. A single lever operation of the twist locks on the skeletal trailers has been fitted in which the twist locks have double-armed levers, the ends of which are connected across the trailer by cables. A close control over container weight is possible at Bell Line because the crane which is used automatically weighs the container when it lifts it. Widetrack axles are specified on the trailers to help their stability and there have been no complaints of excessive roll from the drivers.

Mr. Hamilton's articulated vehicles do 50,000 miles a year on this work. Now that export trade is picking up there is much less empty mileage so that now nearly 80 per cent of the mileage is loaded.

Mr. Hamilton has introduced a comprehensive costing system and points out that the two big items in operating costs are fuel and wages. "If a 45 per cent saving can be shown on one of these it stands to reason that the machine concerned is paying hands down." And that is why he buys Seddons. Moreover, he appreciates the ability to be able to discuss problems with the top men and this makes Seddon very pleasant to deal with as a company. Industrial concerns who run their own goods vehicles are usually anxious to reflect in their fleets the pride they feel in their products. At the same time, a strict control is kept on costs. A pattern of buying policy begins to emerge: to run vehicles that are a little bit better than the run-of-the-mill, but not to pay the earth for them. This is a classic situation for Seddons to fit. They are by no means dear machines and yet have that individual stamp of engineering which lends prestige appeal.

Also, most operators find comfort in the fact that Seddon is not so big that it is a faceless company. Industrial concerns in particular seem to appreciate this, because their operating conditions are often rather special and justify some top-level discussions. As Mr. C. R. Galpin, group distribution director of the Christopher Hill Group of agricultural merchants, pointed out to me, "It helps efficiency, being able to sort out problems quickly by personal contact with the directors." Getting the right specification for the job obviously helps efficiency as well. The Metal Box Company Ltd., for example, first bought Seddons in 1949 because Seddon executives took a keen interest in the Metal Box operating problems and were prepared to tailor standard models to the lengths and wheelbases needed. Since then, Metal Box has found Seddons to be good vehicles at reasonable prices, employing well-proven proprietary units in chassis of straightforward design. "By and large. Seddons have proved very reliable vehicles", said Mr. J. F. Picking, the fleet engineer of Metal Box, "and we are pleased with the present performance of the Perkins 6.354 engines". Metal Box runs over 200 Seddons—about 180 of them being 18-ton artics.

Mr. Picking said that his company's experience was that a 6.354 engine had a typical life of 180,000 miles, which for Metal Box meant about half the life of the vehicle as a whole. Under the Perkins Perpetuity plan a replacement engine costs only £190.

With the Christopher Hill Group, which has 60 Seddons. annual mileages are not as high and the stage of fitting a replacement engine is rarely reached. Vehicles are replaced every five years, and this usually means less than 120,000 miles.

Keeping the weight down Unladen weight is a critical factor for Christopher Hill, said Mr. Galpin, because many of the vehicles are either four-compartment bulk tippers with blowers or are bulk tippers with collapsible sides so that they are convertible into platforms. Both types of body are heavier than ordinary bodies. To have a light, yet reliable, chassis is therefore important. Sometimes the weight is so critical that spare wheels have to be omitted and smaller fuel tanks (30 gal) specified.

A general policy of buying 16-ton gross vehicles is being adopted, to give the greatest freedom of operation in the future when the Transport Bill takes effect. Nevertheless, vehicles must be able to carry at least 10 tons. With the bulk-feed bodies the 16-ton gross Seddons with 6.354 engines can carry this load, but the V8 16:Fours cannot quite make it. In any case. the V8 16:Fours are really too powerful and could stand being derated, thinks Mr. Galpin.

Yet the tractors could do with more power if it were only possible to keep down the weight. In the words of the driver of one of the 20-ton gross artics, "This new one's done 17.000 miles now and there have been no troubles. Reliability's fine. But the 6.354 is struggling a bit when the weight goes over 18 tons. We've got two V8s in four-wheelers —ridiculous really: its these artics that need a VB. And then we've got some of the big ones with Gardner engines. Now those are lovely machines."

The 30-ton Christopher Hill outfits powered by Gardner engines do a much higher annual mileage than the 16and 20-ton gross machines, but are expected to last a couple of years longer before replacement. The group is encouraged to think on these lines because the Gardner engines run since 1965 have never had a spanner on them. Similar types of vehicle are run by Fulford, Trumps and Co. Ltd., based at Bideford, in Devon. This company is now a member of the Rank Hovis McDougall group. It runs ten rigid Seddons of 16-ton gross rating.

This company bought Seddons chassis mainly because of their known record with other companies in the group and their competitive price. Another factor was the Seddon's compact dimensions, for a Seddon with 20-ft-long body is only 25ft. 31in. long overall. Similarly, the wheelbase of 14ft. 8in, gives a tight turning circle.

According to Mr. Ken Fennell, Fulford Trumps transport manager, We had to have 16-ton gross four-wheelers, and Seddons seemed to have more in their favour than any competitive models. Since taking delivery of the first of the Seddons in February, we have had no real troubles with them. The drivers like them very much, too, and their only complaint is engine noise: but we have overcome that by fitting quilted covers over the bonnet".

Not so plain If there was anything to criticize about the Seddons it was usually the cab's plain interior trim. This, felt these operators, was not quite in line with the prestige concept. So the Seddon designers are working on this aspect now. It was a big point with United Biscuits Ltd., the consortium of MacDonald, McVitie and Price, and MacFarlane Lang and Crawford, which runs 28 Seddons.

Most of the C licensees I visited were well satisfied with the fuel consumption of their Perkins-engined Seddons as far as their own types of operation were concerned. At Fulford Trumps they said that their Seddons were averaging between 10 and 11 m.p.g. when they were carrying 11 tons each nearly all the time and the oil consumption appeared to be "definitely better" than that of competitive makes operated previously for the same duties.

It's all, naturally, a matter of horses for courses, but the general impression I got from these C licensees was that Seddon can expect many repeat orders. As Mr, Picking, of Metal Box, said, "We'll continue to buy them so long as Seddon Motors keeps producing up-to-date soundly constructed chassis at competitive prices". There seems no likelihood yet of Seddon falling down on that brief. Any tanker operator keeps a wary eye on weight. Every gallon of payload short is lost revenue. A light chassis which is also reliable is naturally a winner for tanker work. There is increasing evidence that Seddons are filling the bill. One of the Seddon distributors, Ryland Garage Ltd., makes a speciality of selling complete tankers and has found ready custom for models based on the Perkins 6.354engined 16-ton gross Seddon which in perfectly standard trim will carry 3.000 gal. of petroleum spirit. The 13:Four Seddons light weight was a iig attraction for Continental Oil (U.K.) Ltd. as sell.

According to the general supervisor if transportation, 12ft. 6in. wheelbase 3:Four Seddons have been chosen because hey have the right length of frame behind he cab to accommodate existing 2,200 gal pint tanks which have outlived the earlier 7-ton chassis on which they were originally nounted and because the chassis have sufficient weight margin within their plated 3.v.w. of 14 tons to carry this load plus ull metering equipment. The vehicles are )eing used to distribute diesel and motor spirit to industrial customers.

The Seddons are well liked by Conoco irivers, who are particularly pleased with the )raking performance. Despite the long periods )f pumping, the vehicles return 12 m.p.g.

Light weight and reasonable initial cost have )een big factors influencing the choice of i'eddons for a large part of the 32-ton gross .anker fleet of Bulwark Transport Ltd.. 300rehicle Wiltshire-based bulk haulage company. The big attraction of Seddons has been their ight weight", Mr. Reg Rogers, Bulwark's ::hief engineer, told me. The Gardner-engined

-nodels with the coachbuilt cab have a licensng weight of only 4 tons 18 cwt. The Rolls Royce Eagle powered 32:Fours with steel .:abs are approximately half a ton heavier— "Which is a pity-, observed Mr. Rogers, "but they still compare well with most other makes 3f 32-ton tractor."

Cannot afford to be missed

So now, in the 32-ton class, there is not so much weight advantage as there has been in the past, but there is another attraction: value for money. The Bulwark men say they just cannot afford not to buy Seddons. "I don't know how they do it at the price,joked Mr. W. J. Ralph, who manages Bulwark. The 32-ton Seddon is so much cheaper than those of similar specification from other manufacturers. True, there are other tractors as cheap, but Bulwark has found these in most cases heavier, in some cases not as reliable and in other cases with poorer fuel consumption.

Not that Bulwark are actually at the stage where they are definitely standardizing on Seddons. With big buying you cannot afford to make mistakes. and Bulwark is going cautiously on 32:Fours. "Mr. Rogers always says that you have got to do 200,000 miles with a machine before you can be certain whether it is really good", said Mr. Ralph, "but let's say that so far the performance of the Eagle Seddons is encouraging. We've had an Eagle 205 that's done about 50,000 miles now and it has been no trouble at all. We've some 220s as well; but they are not quite as good on fuel consumption as other machines powered by some other engines, but so far they are just as reliable.

It should not take Bulwark long to find -the answer, because they have vehicles doing

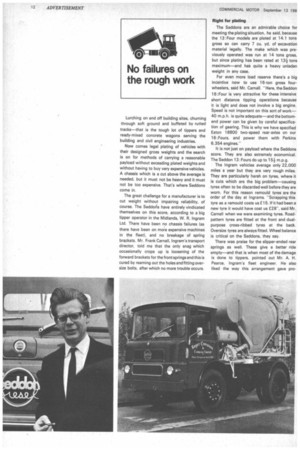

some intensive working right around the clock. Even for that reason alone, they need impeccable reliability. Lurching on and off building sites, churning through soft ground and buffeted by rutted tracks—that is the tough lot of tippers and ready-mixed concrete wagons serving the building and civil engineering industries.

Now comes legal plating of vehicles with their designed gross weights and the search is on for methods of carrying a reasonable payload without exceeding plated weights and without having to buy very expensive vehicles. A chassis which is a cut above the average is needed, but it must not be heavy and it must not be too expensive. That's where Seddons come in.

The great challenge for a manufacturer is to cut weight without impairing reliability, of course. The Seddons have entirely vindicated themselves on this score, according to a big tipper operator in the Midlands, W. R. Ingram Ltd. There have been no chassis failures (as there have been on more expensive machines in the fleet), and no breakage of spring brackets. Mr. Frank Carnall, Ingram's transport director, told me that the only snag which occasionally crops up is loosening of the forward brackets for the front springs and this is cured by reaming out the holes and fitting oversize bolts, after which no more trouble occurs. Right for plating The Seddons are an admirable choice for meeting the plating situation, he said, because the 13 :Four models are plated at 14.1 tons gross so can carry 7 Cu. yd. of excavation material legally. The make which was previously operated was run at 14 tons gross, but since plating has been rated at 131 tons maximum—and has quite a heavy unladen weight in any case.

For even more load reserve there's a big incentive now to use 16-ton gross fourwheelers. said Mr. Carnal!. "Here, the Seddon 16 :Four is very attractive for these intensive short distance tipping operations because it is light and does not involve a big engine. Speed is not important on this sort of work40 m.p.h. is quite adequate—and the bottomend power can be given by careful specification of gearing. This is why we have specified Eaton 18800 two-speed rear-axles on our 16 :Fours, and power them with Perkins 6.354 engines."

It is not just on payload where the Seddons score. They are also extremely economical. The Seddon 13 :Fours do up to 15+ m.p.g.

The Ingram vehicles average only 22,000 miles a year but they are very rough miles. They are particularly harsh on tyres, where it is cuts which ate the big problem causing tyres often to be discarded well before they are worn. For this reason remould tyres are the order of the day at Ingrams. "Scrapping this tyre as a remould costs us £15. If it had been a new tyre it would have cost us 28", said Mr. Carnall when we were examining tyres. Roadpattern tyres are fitted at the front and dualpurpose cross-ribbed tyres at the back Oversize tyres are always fitted. Wheel balance is critical on the Seddons, they say.

There was praise for the slipper-ended rear springs as well. These give a better ride empty—and that is when most of the damage is done to tippers, pointed out Mr. A. H. Pearce, Ingram's fleet engineer. He also liked the way this arrangement gave pro gressive strength as the load increased.

Fat singles To save weight in the future Ingram's are thinking of fitting tubeless tyres and perhaps fat singles on the back. This will also reduce the mud deposition on roads. They will also order 20 gal. fuel tanks because these vehicles return to base every night and the daily mileages are not high.

It is very convenient to be able to buy a complete tipping vehicle from a manufacturer, in Mr. Carnall's opinion, and this is the case with Seddon because the steel tipping bodies are built by Seddon's associate coachbuilding company, Pennine Coachcraft Ltd. For lngrams a in. thick floor instead of an lin.

thick floor is fitted and the 7 cu. yd. bodies have rear-ends and tailboards normally fitted to 8 cu. yd. bodies. This means that the tail boards swing from a high point and this aids load discharge. Extra side ribs for the body are also specified by Ingram. Underbody tipping gear is preferred because there is less risk of ram distortion from body sway, it has been found.

A feature on the back axle which is particularly liked by Mr. Pearce is the way the hub drive is taken through bolts rather than through studs. When studs are used they soon loosen or break, he reports.

Drivers at Ingram say they like the cab. It stands up well to the punishing work and gives much safer access with its low forward entry. This can be quite a factor when drivers are climbing in and out of the cab and they are wearing gum-boots which likely as not have slippery mud on the soles.

Much the same story came from Mr. A. K. Gabszewicz, a director of Roger Constant and Co. Ltd., at Stourport-on-Severn, in Worcestershire. This company has its own gravel pit and ready-mixed concrete business.

This is the modern pattern in the building industry, of course, and the effect on the transport operation has often been such that it is not so much the tippers which get the dirty end of the stick, but the ready-mixed concrete wagons delivering direct to the sites. The Seddons still fill the bill admirably, it seems.

Asked why his company bought Seddons in the first place. and had virtually standardized on this make. Mr. Gabszewicz had no hesita tion in replying that prices and delivery dates played a major part in his company's purchas ing policy. At a time when fleet replacements were urgently required. Seddon had continued to be able to sell the right vehicles at realistic prices and early delivery dates, so his company had continued to buy chassis of this make.

The Constant fleet consists of 36 Seddons of various ages, sizes and types, supplemented by several older vehicles of other makes which are being progressively replaced by Seddons. The 36 comprise 18 tippers for sand and gravel, 16 truck mixers and two cement tankers. Among these are four-wheelers running at 12, 13. 14 and 16 tons gross; Primrose and U nipower six-wheeled conversions, both singleand double-drive, a doubledrive eight-wheeler and a 20 tons gross 4 by 2 tractor.

All the Constant tippers are fitted with Pennine bodies. initially, the company specified bodies of aluminium alloy, but subsequent operational experience showed that such bodies were not strong enough for the particular job. Consequently. all-steel construction was specified for the Pennine bodies on later vehicles, and these are not giving any cause for complaint. The two cement tankers —an eight-wheeler of 15 tons payload capacity and a Seddon-Primrose six-wheeler that can carry 12 tons—have Carmichael tipping tanks equipped for pneumatic discharge. Dutch-made Muller concrete mixers are fitted to the early truck-mixer chassis, but the majority of these chassis are more up-todate models carrying Ritemixer independently powered concrete mix6rs.

Fuel consumption in the Constant fleet varies from vehicle to vehicle, not only because of the different gross weights at which they run but also because of the different engines fitted. The consurr ption rate of the 6.354-engined tippers and truck mixers ranges between 11 and '14 m.p.g., according to gross weight. while ihat of the tractor fat 20 tons gross) is about 9 m.p.g.

At Constants there was a feeling that Seddon sales had grown so fast that the time had come for proper Seddon spare-parts depots to be established in strategic areas: "We can always get the slower-moving spares from Oldham, but this ,s a day's journeying and we'd like a Midlands depot." But when asked, "Will you buy Seddons again, Mr. Gabszewicz?----Yes". came he prompt reply.