AEC V8 TRACTIVE UNIT FOR 28 TONS

Page 133

Page 132

If you've noticed an error in this article please click here to report it so we can fix it.

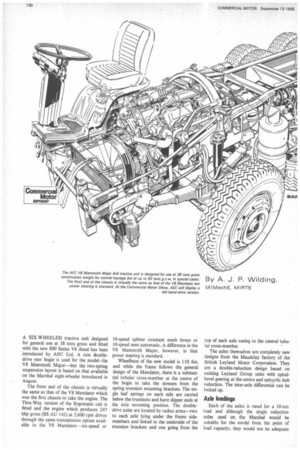

By A. J. P. Wilding, M I MechE, M1RTE A SIX-WHEELED tractive unit designed for general use at 38 tons gross and fitted with the new 800 Series V8 diesel has been introduced by AEC Ltd. A new doubledrive rear bogie is used for the model--the V8 Mammoth Major—but the two-spring suspension layout is based on that available on the Marshal eight-wheeler introduced in August.

The front end of the chassis is virtually the same as that of the V8 Mandator which was the first chassis to take the engine. The Thru-Way version of the Ergomatic cab is fitted and the engine which produces 247 bhp gross (BS AU 141) at 2,600 rpm drives through the same transmission option available in the V8 Mandator—six-speed or 10-speed splitter constant mesh boxes or 10-speed semi-automatic. A difference in the V8 Mammoth Major, however, is that power steering is standard.

Wheelbase of the new model is 1111 6in. and while the frame follows the general design of the Mandator, there is a substantial tubular cross-member at the centre of the bogie to take the stresses from the spring trunnion mounting brackets. The single leaf springs on each side are carried below the trunnions and have slipper ends at the axle mounting position. The doubledrive axles are located by radius arms—two to each axle lying under the frame sidemembers and linked to the underside of the trunnion brackets and one going from the

top of each axle casing to the central tubular cross-member.

The axles themselves are completely new designs from the Maudslay factory of the British Leyland Motor Corporation. They are a double-reduction design based on existing Leyland Group units with spiralbevel gearing at the centre and epicyclic hub reduction. The inter-axle differential can be locked up.

Axle loadings Each of the axles is rated for a 10-ton load and although the single reduction axles used on the Marshal would be suitable for the model from the point of load capacity, they would not be adequate for 38 tons gross combination weight in conjunction with the V8 engine—even less the 50 tons g.c.w. at which the tractive unit can be used in approved cases.

The bogie weight limit—by the suspension—is 16 tons and the front axle rating is 6.5 tons.

The AEC Stand at the Commercial Motor Show will feature a left-hand drive version of the model with 6.9 to 1 axle ratio and the chassis will have 11.00-20 tyres. Because it is designed for export markets the Show vehicle will have a two-line airpressure braking system. The brakes in this case are split, with the front axle and bogie axle independent of each other. AEC would normally link one of the rear axles with the front axle but the standardization of light /laden equipment for the bogie brakes does not allow this to be done.

The brake actuators on the front and rearmost axle are the double-diaphragm ' lock type and while these provide mainly for parking the secondary sides of the front-axle actuators are pressurized with the brake line to the trailer on application of a hand valve in the cab.

SUrpliSing The brake system is open to modification to meet the particular needs of any market in which the model is sold and it is surprising that for UK three-line systems only the front axle of the 6 x 4 tractive unit will be used for the secondary system in conjunction with the auxiliary line to the trailer. This is particularly so when the equipment is there to give a first and third axle secondary brake to meet this need.

Brake sizes on the V8 Mammoth Major 6 x 4 tractive unit are 15.5in. diameter drums all round with 6in. wide shoes at the front axle and 7in. at both rears. The Show model will have an exhaust brake and steering lock and in addition to normal warning lights and gauges, the instrumentation will include tachometer and tachograph. The instruments are housed in the latest-design binnacle used in the Ergomatic cab.

Estimated chassis cab weight of the model is 7 tons 15ewt.