A NEW TYPE OF TRAILER.

Page 9

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

The Adoption of Ackerman Steering Tends to the Solving of Many Problems.

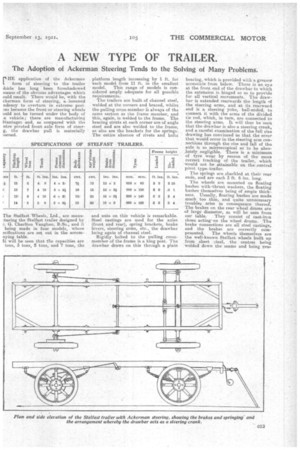

['HE application of the Ackerman L form of steering to the trailer ihicle has long been foreshadowed cause of the obvious advantages which ould result. There would be, with the ckerman form of steering, a lessened ndency to overturn in extreme posims because the front or steering wheels mild not be turned under the body of e vehicle; there are manufacturing l4antages and, as compared with the ntre pivoted front axle farm of steerg, the drawbar pull is materially isened.

The Stelfast Wheels, Ltd., are menuduring the Stelfast trailer designed by r. G. Charlton Vaughan, B.Sc., and it being made in four models, whose ecifications are set out in the aceomnying table. ft will be seen that the capacities are tons, 3 tons, 5 tons, and 7 tons, the

platform length increasing by 1 ft. for each model from 11 ft. in the smallest model. This range of models is considered amply adequate for all possible requirements.

The trailers are built of channel steel, welded at the corners and braced, whilst the pulling cross-member Is always of the same section as the frame member, and this, again, is _welded to the frame. The bracing struts at each corner are of angle steel and are also welded to the frame, as also are the brackets for the springs. The entire absence of rivets and bolts and nuts on this vehicle is remarkable. Steel castings are used for the axles (front and rear), spring brackets, brake levers, steering arms, etc., the drawbar being again of channel steel. Rigidly. bolted to the pulling crossmember of the frame is a king post. The drawbar draws on this through a plain

bearing, which is provided with a greaser accessible from below. There is an eye at the front, end of the drawbar to which the extension is hinged so as to provide for all vertical movements. The drawbar is extended rearwards the length of the steering arms, and at its rearward end is a steering yoke, ball-ended, to connect it with the arms of the divided tie rod, which, in turn, are connected to the steering arms. It, will thus be seen that the drawbar is also a steering crank, and a careful examination of the full size drawing has convinced us that the error that would occur in the steering arm connections through the rise and fall of tho axle is so microscopical as to be absolutely negligible. There is a minimum of tyre wear by reason of the more correct, tracking of the trailer, which would not be attainable on the central pivot type, trailer.

The springs are shackled at their rear ends, and are each 3 ft. 6 ins. long.

The wheels are mounted on floating bushes with,thrust washers, the floating bushes themselves being of ample thickness. Usually, floating bushes are made much too thin, and quite unnecessary troubles arise in consequence thereof. The brakes on the rear wheel drums are of large diameter, as will be seen from our table. They consist of cast-iron shoes acting on the wheel drums The brake connections are all steel castings, and the brakes are correctly cons. pulsated. The wheels themselves are the well-known Stelfast wheels built up from sheet ;steel, the centres being welded down the seams and being pre vided with steel web plates which, in their turn, are welded to the rim. A stamped litila centre is inserted after the spokes have been welded to the frame, and this is -welded round the inner 6111S of the spokes, afterwards a taper mandril is hydraulically pressed through the wheel centre. Whilst the centre is thus in a state of expansion, a cast-iron cornpression ring of the diameter of the thickest-part of the mandril is then inserted, thus freeing the mandril and leaving the ring tautly compressing the bub ends of the spokes. The wheels having been faced on both sides and the compression ring bored true to the circumference of the rim, the brake drum is screwed to the hub by bolts which liass through solid plugs inserted in the spokes, welded in position and drilled to jig to receive, the bolts, which are a driving. fit. A nave plate of light sheet steel is next welded into position, and this completes the construction of a typeof -wheel which is proving so Successful that the London general Omnibus Co. has just placed-an order for a'quantity. Fitted to the trailer it is equipped with a hub cap which, when filled with grease; acts as a receptacle for one week's supply of lubricant to the bearing.

The address of the manufacturers is Stelfast Wheels, Ltd., 121, Kingsway, London, W.C. 2, the works being at 51.53, Effra Road, Brixton, London, S.W. 2. 1The sales and business side of

the concern is managed by Mr. R. ( Warren at the Kingsway_ office, whil the works are under the charge Mr. Vaughan.