ROADSIDE AND GARAGE.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

A Page for

Drivers,. Mechanics and Foremen.

Extemporized Propeller Shaft.

nder of the following communication been awarded the extra payment of his week.

5] " J.T." (Leeds).—"I discovered in an awkward predicament reowing to the breakage of a leather ag at the rear end of the propeller The occasion was rendered more

inasmuch as when the coupling it had the effect of bending the ler shaft, and rendering that, too, 1. I had just got out the tow rope t consists of a length of steel wire , link at each end) when it occurred that I might make use of this to the wagon instead of towing it, by rig the universal joint, at the rear gearbox to that at the front of the ale. This I did quite successfully following manner.

prepared a length of stout timber 'edged it tightly between the two I then bolted one end of he tow to the front coupling, wound it the timber in the proper manner I arrived at the rear coupling and the other nut to that one. When tgine was started and low gear enthis completed the winding operaand tightened the rope on to the ening timber making quite a solid it, and with this unusual makeshift able to travels matter of quite 30 without further difficulty. here was one thing, of course, which essential to guard against and that flowing the vehicle to over-run the as m that case the rope would been unwound. Additionally, one ) bear in mind that the foot brake bsolutely useless."

mei Method of Repairing a Broken Spring.

36] " HE." (Moreton-in-Marsh) :--" A short time ago, owing to isgraceful 'state of the roads over r was journeying, .I had the //lisle to break. the top leaf of one of ad springs, close to the bush. Hayspare spring, I lost no time in fit.in place of the.broken one. Two later on, the other front spring , in almost exactly the same place. no more spares, and had to try to a new spring out of the two broken Whit I did was to take the two saves, and cut, them both through mtre, on the 'slant, as shown in the 1, I then riveted, a thin plate 3 the, top, so that the two plates were held together, and then mounted the spring, with this improvised top leaf in place, BO that the spring clips bore on to the plate and held the whole firmly in position. As shown in the diagram, the leaves were so cut that the point of each projected well beyond the clips. Although this repair waS carried out on a three-ton lorry which has been in regular use since, working every week-day and Sundays, it has so far given no trouble."

Re-grinding Valves.

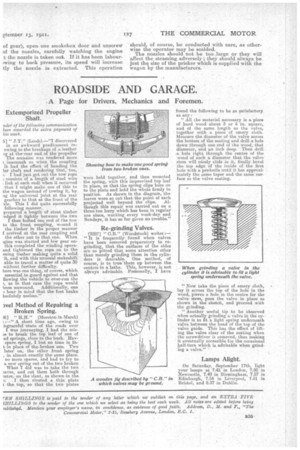

[2287] " 0.B." (Woodstock) writes :— " It is frequently found when valves have been removed preparatory to regrinding, that the surfaces of the sides are so pitted that seine attention other than merely grinding them in the cylinders is desirable. One method, of course, is to trner'them up between the centres in a lathe. This, however, is not al/ways advisable. Pensonally, T have

found the following to be as satisfactory as any :

" All the material necessary is a, piece of hard wood about 3 or 4 in. square, and of the same length as the valve, together with a piece of emery cloth. Measure the diameter of the valve across the bottom of the seating and drill a hole down through one end of the wood, that diameter, and an inch deep. Then drill ,a hole right through the centre of the wood of such a diameter that the valve stem will nicely slide in it, finally bevel the top edge of the inside of the first hole with a penknife until it has approximately the same taper and the same surface as the valve seating.

"Now take the piece of emery cloth, lay it across the top of the hole in the wood, pierce a hole in the centre for the valve stem, pass the valve in place as shown in the sketch, and proceed with the grinding.

"Another useful tip to be observed when actually grinding a valve in the cylinder is to fit a light spring underneath valve between the head of the top of the valve guide. This has the effect of lifting the valve clear of the seating when the screwdriver is removed, thus making it eventually accessible for the occasional half-turn which is advisable when grinding a valve."

Lamps Alight

On Saturday, September 17th, light your lamps at 7:41 in London, 7.50 in Newcastle, 7.49 in Birmingham, 7.57 in Edinburgh, 7.54 in Liverpool, 7.51 in Bristol, and 8.37 in Dublin.