• 'THE RALLS 5-TON CHASSIS.

Page 12

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

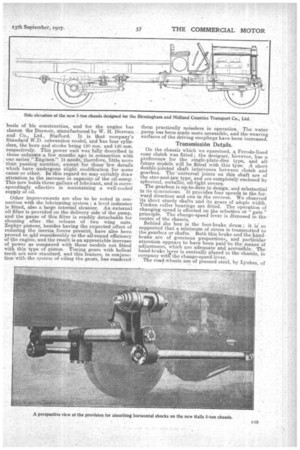

A New Product, Designed by an Engineer Who is an .Experienced User.

ANEW five-ton chassis, which, in the main, is of British manufacture, is certainly not quite what the reader would expect to find described • in the columns of DIE COAiliERCIAL MOTOR in present ;circumstances, however much he might think such a consummation to be necessary or desirable. Yet we find ourselves so placed as to be able to present such a description, and, moreover, our subject is a product

that we can fully commend for close examination. ,

The chassis-in question is named the BirminghamTransport. (Its name, we think, is the feature which is least worthy of approval, on accountof its unwieldiness.) Its designer is Mr. G. E. D. Rails, M.I.Mech.E., the managing director of that wellknown concern, the Birmingham and Midland Counties Transport Co. Ltd. This companyowns a large fleet of commercial vehicles of all weights and types (reference was made to its activities in the course of an article which appeared in these Columns on the 28th of June last). The designer, therefore, possesses that special knowledge which results from• the combination of scientific engineering training with wide first-hand experience of the actual use, under commercial conditions, of heavy vehicles.

Mr. Rails, moreover, has another important qualification, as a consideration of the design of his chassis, failing, on the part of the reader, a personal acquaintance, will prove. He has originality, and is not afraid of putting ideas into practice, which may involve departures from conventional design. = The result is, as we have stated, a fine chassis, incorporating novelties of construction, particularly in respect of its suspension. The latter is a notable ac vance on current practice.

• The Machine. is constructed to carry a useful load c • five. tons ; its appearance is such as to impress th beholder with the notion that it will successfully coi vey that load, and "never feel it." In this connectio we may, without endorsing the opinions expressec quote the designer, "The maker of a steam wa,go never thinks it necessary to warn a buyer again overloading his chassis, the manufacturer of petro driven • vehicles, • however, invariably warns h customer `against the dreadful evils of this practice

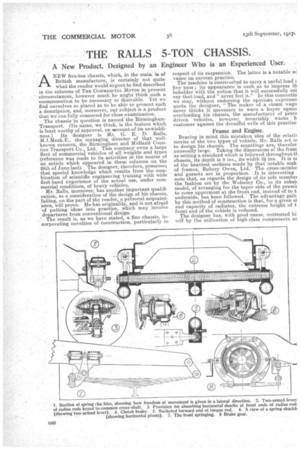

• Frame and Engine.

• Bearing in mind this mistaken idea of the relatil merits of the two types of vehicle, Mr. Rails set.oi to design his chassis. The scantlings are therefor _unusually large. Taking the dimensions of the fram as setting a standard which is followed throughout tl chassis, its depth is 8 ins., its width 21 ins. It is 01 of the heaviest sections made by that notable mak of frames, Rubery Owen, Ltd. The cross-morabe and gussets are in proportion. It is interesting note that, as regafds the design of its-side membei the fashion set by the Wolseley Co., in its sulasii model, of arranging for the taper side of the pressii to come uppermost at the front end, instead of to t underside, has been followed. The advantage gain by this method of construction is that, for a given si and capacity of radiator, the extreme height of t front end of the vehicle is reduced.

The designer has, with good cause, contented hi: self by the utilization of high-class components as

basis of his construct-ion, and for the engine has chosen the Dorman, manufactured by W. H. Dorman and Co., Ltd., Stafford,. It is that company's Standard W.D. subvention model, and has four cylinders, the bore and stroke being 120 mm. and 140 ram. respectively. This power unit waslully described in these columns a few months ago in connection with our series ".Engines." It needs, therefore, little more than pasting mention, except for thosefew details which have undergone slight modification-. for some cause or other. in this regard we may .suitably draw attention to the increase in capacity of the ail-sump. This now holds three gallons of lubricant, and is correspondingly effective in maintaining a well-cooled supply of oil.

Other improvements are also to be noted in -.connection with the lubricating system ; a level indicator is fitted, also a large internal strainer. An external oil filter is provided on the delivery side of the pump, and the gauze of this filter is readily detachable for cleaning after the release of two wing nuts. Zephyr pistons, besides• having the expected effect of reducing the inertia forces present, have also been proved to add considerably to the all-round efficiency of the engine, and the result is an appreciable increase of power as compared with those models not fitted with this type of. piston. Timing gears with helical teeth are now standard, arid this feature, in conjunction with the system of oiling the gears, has rendered

them practically noiseless in operation. The water pump ilEbS been made more accessible, and the wearing surfaces of the driving couplings have been increased.

Transmission Details.

On the chassis which we examined, a Ferodo-dined cone clutch was fitted; the designer, however, has a preference for the single-Plate-disc type, and all future models will be fitted with this type. A short double-jointed shaft intervenes between clutch and gearbox. The' universal joints on this shaft are of the star-and-jaw type, and are completely enclosed by spherical, metallic, oil-tight covers. The gearbox is up-to-date in design, and substantial in'its dimensions. It provides four speeds in the forward direction and one in the reverse. We observed its --short sturdy shafts and its gears of enple width. Timken roller hearings are fitted. The operation of changing speed is effected on the selective dr " gate " principle. The change-speed fever is disposed in the

centre of the chassis. •

Behind the box is the foot-brake drum ; itis' so supported that a minimum of stress is transmitted to the gearbox or shafts. Both this brake and the handbrake are of generous proportions, and particular attention appears to have been paid to the means Of adjustment, which are adequate and accisible. The hand-beake liver is centrally placed in the chassis, in company with the change-speed lever.

The road-wheels are of pressed steel, by Lynton, of

Warrington ; they are of the disc type, giving ease of cleaning, strength, lightness and durability. Those at the rear are of a size to accommodate twin tyres of 140 mm. section, and 1030 mm. diameter. The front wheels carry single tyres 140 rem. by 000 mm.

The propeller shaft between gearbox and backsaxle is fitted with universal joints pimilar to those which have already been described with reference to the clutch shaft. The necessary provision for telescopic action is, of course, afforded. The rear axle is wormdriven, of the full-goating type. The features of the construction, of this unit are too we1l-kno4n to—need any lengthy description now. The name of its maker (David 'Brown and Sons, Ltd., of Huddersfield) is a sufficient 'guarantee of its reliability 'andof the soundness of its design.

'New System of Springing.

We come now to the " piece de resistance " of this chassis : its springs: Mr. Ralls has for a number of years made a study of the suspension of automobiles ; the springing of this vehicle is one outcome of that study. That it represents an advance on current practice will readily be conceded, on consideration of the design. We are of that opinion, and moreover, wehave confirmed our opinion by personal tests of a vehicle over some.atrocious, road surfaces.

Full consideration of this, as indeed of any complete system of springing, can only he made by includ. ing in such consideration the design of the radius and torque rods. That this is a point which is not generally realized we well know ; it is, however, an important one, and one to' which we have drawn attention of late.

While senz i-elliptic springs are capable, within reasonable limits, of accommodating the vertical components of road shocks, there is need for some method of absorbing the horizontal components of these shocks. On pneumatic-tyred vehicles this cushioning effect is provided, to a great extent, by the tyres themselves' on-solid-tired machines, additional provision must be made. The place for this is, for the rear axle at least, on the radius rods. In this opinion Mr. Rails concurs, as an examination of his

design reveals. . • To describe then, the springing. At the rear, semielliptic springs of customary design are attached to the axle through the medium of bearings on journals on the outside of the axle case. These springs are shackled at both ends, and the shackles are supported on pivots which allow freedom of movement in a lateral direction. The springs are not called upqn to perform any work but the primary one of absorb ing shocks. This, in itself, is a step in the right direction. The torque reaction is taken by a built-up steel beam, carried by a vertical pivot at its rear end, its front ball end being supported in a socket which is carried from a tubular cross member of the main frame. 'This also is an example of the principle of design in which a component is confined in use to its proper function.

Radius Rods Keyed to Common Cross-shaft.

Th torque,rod,allows`motion in all directions ex.cept in its own plane. The radius rods are two in number. Each is attached at its rear ond to one of the spring brackets. Their front ends are spherical and bear in sockets on two-armed levers. These levers are vertically, disposed, are keyed to a common crossshaft, and their upper ends are each held between two powerful helical taper coil springs. Herein is the provision for absorbing horizontal shocks'. The design is fully protected by patent.

On the front springs a similar arrangement is a,dopted. It can in conjunction with what we 'have already written, 'be understood by reference to the drawing which we reproduce. In this case, however, there is also incorporated an ingenious method c50 of catering for unusually heavy blows, which deserves particular mention. The vertical vibrating lever has, formed integral with it, a cam, and this cam, on the spring receiving an unusually heavy blow, bears on the top of the spring itself, at a point a few inches forward of the rear shackle. The effect is to reduce the leverage of the load on the spring, which is in consequence able to offer a better resistance. It becomes, in fact, temporarily, a stiffer spring. The extent of the effect which these devices have on, the riding qualities of the chassis is beyond belief. The loaded vehicle rides with a steady even motion which is more like that of a railway truck than of a road wagon. There is a saarkegi reduction, too, in the jar.which is experienced when letting in the clutch to start, or after changing gear. On a rough, wavy road the horizontal springs are seen to be in a constant state of dither. A similar and not less noticeable improvement is apparent when running light. Of itself this is sufficient justification for the adoption zif the Rail& system of springing, there being no doubt whatever in the minds of most users and makers of commercial vehicles that high-speed running of unloaded machines accounts for more than a half share of the normal depreciation. It is possible to sit on an ordinary chair which is stood in the body of a Rails lorry, the lorry being otherwise unloaded, and to be driven at normal road-speed with comparative comfort.

Other Novel Features.

We have not exhausted the good points of this chassis ; there are others, of importance, but they have a less -compelling interest, comparatively, than ,those to wt. sch we have referred. This description would not be a comprehensive one, however, if we

omitted to mention the system of lubrication which has been adopted for the miscellaneous pin joints. lever bearings, brackets and other wearing part which are distinct from those already catered for b3 the engine, gearbox and rear axle oiling systems. Each of these bearings, instead of. as is customary being fitted with a screw-down grease cup, is pro. vided with a steel ping. Each plug is hollow, ths otherwise open aperture being closed 'by a sprini button. Every plug is screwed externally to fit tin 'end of a grease gun. Users of Sentinel steam wagont will be familiar with this method. As will be realized it considerably facilitates the rapid and complett lubrication of those oft-neglected parts. Regular deliveries of this chassis are not at tin moment possible, for reasons which are more or les obvious. Readers who have prospective use for t five-ton petrol chassis will do well, nevertheless, ti communicate with the maker, the Birmingham am Midland Counties Transport Co., Ltd., at 312-314 Bradford Street, Birmingham.