The Wakefield Lubricator.

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

The smoky vapour, which is occasionally emitted from the end of the exhaust pipe of a petrol engine, is a source of annoyance to the public, and a trial to the engineer who is responsible for the running of the vehicle. The trouble can be generally attributed to one of two causes; these are, either the unintelligent adjustment of the valve, or valves, which determines the quantity of oil passed to the engine, or the unsuitability of the lubricator itself for the work which it has to perform. A heavy oil bill is the natural corollary to smoky exhausts, and, although it may be preferable to pay for extra oil rather than to have to renew bearings, or to suffer the cost of a fractured connecting rod, it should not, at this stage of motorbus construction, be necessary to have recourse to such a crude precautionary method, Over-lubrication may be necessary for the first few miles which are traversed by a new vehicle, as bearings which have only the shop finish on them cannot be expected to run for a long initial journey without some signs of beating. On the other hand, vehicles may be seen passing along some of our principal thoroughfares with a cloud of blue smoke following them, and most of these have been in service for some considerable period.

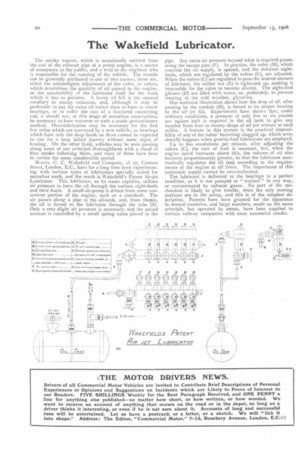

Messrs. C. C. Wakefield and Company, of 27, Cannon Street, London, EC., have for a long time been experimenting with various types of lubricators specially suited for motorbus work, and the result is Wakefield's Patent Air-jet Lubricator. This lubricator, as its name explains, utilises air pressure to force the oil through the various sight-feeds and their ducts. A small air-pump is driven from some convenient portion of the engine, such as a camshaft. The air passes along a pipe to the oil-tank, and, from thence, the oil is forced to the lubricator through the tube (A). Only a very slight air pressure is necessary, and the actual amount is controlled by a small spring valve placed in the pipe. Any extra air pressure beyond what is required passes along the escape pipe (F). In practice, the valve (M), which controls the oil supply, is opened, and the difierent sightfeeds, which are regulated by the valves (C), are adjusted. When the valves (C) are regulated to pass the desired amount of lubricant, the milled nut (E) is tightened up, making it impossible for the valve to become altered. The sight-feed glasses (D) are filled with water, or, preferably, to prevent freezing in the cold weather, glycerine. Our sectional illustration shows how the drop of oil, after passing by the conduit (H), is forced to its proper bearing by the air jet (G). Experiments have shown that under ordinary conditions, a pressure of only five or six pounds per square inch is required in the oil tank to give any number from four to twenty drops of oil per minute at each orifice. A feature in this system is the practical impossibility of any of the tubes' becoming clogged up, which oceasionally happens when gravity-feed lubricators are employed.

Up to Soo revolutions per minute, after adjusting the valves (C), the rate of feed is constant, but, when the engine speed increases above this, the volume of oil also becomes proportionately greater, so that the lubricator automatically regulates the oil feed according to the requirements of the engine at all times. The importance of this automatic supply cannot be over-estimated. The lubricant is delivered, to the bearings in a perfect condition, as it is not pumped or " worked" in any way, or contaminated by exhaust gases. No part of the mechanism is likely to give trouble, since the only moving portions are in the pump, and this is of the simplest description. Patents have been granted for the apparatus in several countries, and large numbers, made on the same principle, but operated by steam, have been supplied to various railway companies with most successful results.