Road and Rail Co-ordination

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

in milk transport OP the different schemes under consideration for co-ordinated road and rail working one of the most interesting, and one with almost limitless possibilities, is that which is being tried out in connection with the bulk conveyance of milk. In brief it consists in the employment of an unusual road tank wagon and a special form of rail truck for transporting 2,000 gallons of milk from

the depot of the Co-operative Wholesale Society, at Bruton, in Somerset, to the aiding adjoining the company's premises at Clapham Junction,'London.

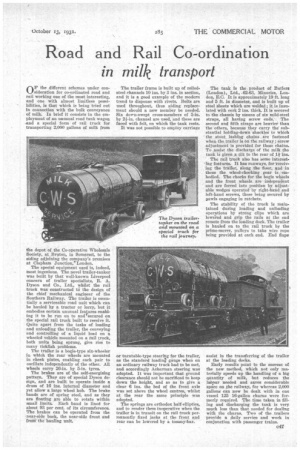

The special equipment used is, indeed, most ingenious. The novel trailer-tanker was built by that well-known Liverpool concern of trailer specialists, R. A. Dyson and Co., Ltd.' whilst the rail

truck was constructed the design of the chief mechanical engineer of the Southern Railway. The trailer is essentially a serviceable road unit which can be hauled by a tractor or lorry, but it embodies certain unusual features enabling it to be run on to and qecured on the special rail truck built to receive it. Quite apart from the tasks of loading and unloading the trailer, the conveying. and controlling of a liquid load on a wheeled vehicle mounted on a rail truck, both units being sprung, give rise to many ticklish problems.

The trailer is a bogie-type six-wheeler in which the rear wheels are mounted in cheek plates, enabling each pair to oscillate independently of the other. All wheels carry 26-in. by 5-in. tyres.

The brakes are of the self-energizing pattern. They are of special Dyson design, and are built to operate inside a drum of 16 ins. internal diameter and yet allow a large wheel hub. The brake bands are of spring steel, and as they are floating are able to rotate within small limits. Each baud is lined for about 93 per cent, of its circumference. The brakes can be operated from the near-side back, the near-side front and froth' the• hauling unit.

The trailer frame is built up of roiledsteel channels 10 ins. by 3 ins, in section, and it is a good example of the modern trend to dispense with rivets. Bolts are used throughout, thus aiding replacement should a new member be needed. Six down-swept cross-members of 5-in. by 2i-in. channel are used, and these are faced with felt, on which the tank rests.

It was not possible to employ 'carriage

or turntable-type steering for the trailer, as the standard loading gauge when on an ordinary railway truck had to be met, and accordingly Ackerman steering was adapted. It was important that ground clearance should not be sacrificed to keep do-wn the height, and so as to give a clear 6 ins, the bed of the front axle was set above the wheel centres, whilst at the rear the same principle was adopted.

The springs are orthodox half-elliptic, and to render them inoperative when the trailer is in transit on the rail truck permanently fixed jacks at the front and rear can be lowered by a tommy-bar.

The tank is the product of Butlers (London), Ltd., .62-63, Minories, London, E.G. It is approximately 19 ft. long and 5 ft. in diameter, and is built up of steel sheets which are welded; it is insulated with cork 2 ins. thick. It is secured to the chassis by means of six mild-steel straps, all having screw ends. The second and fifth straps are heavier• than the others, because they carry the' substantial holding-down shackles to which the stout. lashing chains are fastened when the trailer is on the railway ; screw adjustment is provided for these chains. '.l'o assist the discharge of the milk the tank is giyen _a tilt to the rear of 11 ins.

• The rail trues also has some interestfag features. It has runways, for receiving the trailer, along the floor, and in these the wheel-chocking gear is embodied. The chocks for the bogie wheels and the front wheels are independent and are forced into position by adju-stable wedges' operated by right-hand and left-hand screws, these being secured by pawls engaging in ratchets.

The stability of the truck is maintained during loading and unloading operations by strong clips which are lowered and grip the rails at the end remote from the loading dock. The trailer is hauled on to the rail truck by the prime-mover, pulleys to take wire rope being provided at each end. End flaps assist in the transferring of the trailer at the loading docks.

Early results point to the success of the new method, which not only materially speeds up the handling of a big quantity of milk, but reduces the lalpur needed and saves considerable space on .the railway, for whereas 2,000 gallons can now be dealt with in one vessel 125 16-gallon churns were formerly required. The time taken in filling and discharging the tank is very much less than that needed for dealing with the churns. Two of the trailers provide a daily service and work in conjunction with passenger trains.