HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

ONTRIBUTIONS are invited for th's page from fleet managers, drivers, garage foremen, and mechanics, -works staff and draughtsmen, and will be polo for on a generous scale. Every system, make, and typo of commercial motor vehicle is being dealt with, and the matter should be Written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle:

It often happens that even a normal practice, or a practice peculiar to a particular type of vehicle is. not generally known. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, dealing with letters from our driver and mechanic readers. Communications should be addressed to "The Editor, The Commercial Motor, 7-15, Rosehery Avenue, London,.E.C.1."

644.—Curing an Oil Leakage in the Peerless Engine.

The engines on Peerless lorries are usually lubricated with a thin oil, and leakages generally occur from various points. This hint shows how one such leakage —and a serious one at that—can be arrested, thus effecting a considerable economy in lubricating oil.

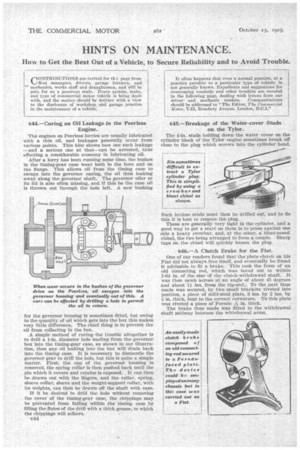

After a lorry has been running some time, the bushes in the timing-gear case wear both in the bore and on the flange. This allows oil from the timing case to escape into the governor casing, the oil then leaking away along the governor shaft. The governor oiler or Its lid is also often missing, and if this be the case oil Is thrown out through the hole left. A new bushing

for the governor housing is sometimes fitted, but owing to the quantity of oil which gets into the box this makes very little difference. The chief thing is to prevent the oil from collecting in the box.

A simple method of curing the trouble altogether is to drill a fin, diameter hole leading from the governor box into the timing-gear case, as shown in our illustration, then any oil leaking into the box will drain back into the, timing ease. It is necessary to dismantle the governor gear to drill the hole, but this is quite a simple matter. First, the cap of the governor housing is removed, the spring collar is then pushed back until the pin which it covers and retains is exposed. It can then be drawn out with the fingers, and the collar, spring, sleeve collar, sleeve and the weight-support collar, with its weights, can then be drawn off the shaft with ease.

If it be desired to drill the hole without removing the cover of the timing-gear case, the chippings may be prevented from falling within the timing case by filling the flutes of the drill with a thick grease, to which the chippings will adhere.

645.—Breakage of the Water-cover Studs on the Tylor.

The ft-in, studs holding down the water cover on the cylinder block of the Tylor engine sometimes break off close to the plug which screws into the cylinder head.

Such broken studs must then be drilled out, and to do this it is best to remove the plug.

These are generally very tight in the cylinder, and a good way to get a start on them is to press against one side a heavy crowbar, and, at the other, a blunt-nosed chisel, the two being arranged to form a couple. Sharp taps on the chisel will quickly loosen the plug.

646.—A Clutch Brake for the Fiat.

One of our readers found that the plate clutch on his Fiat did not always free itself, and eventually he found it advisable to fit a brake. This took the form of an old connecting rod, which was bored out to within 1-64 in. of the size of the clutch-withdrawal shaft. It was then sawn across at an angle of about 45 degrees and about 14 ins, from the big-end. To the part thus made was secured, by two small brackets riveted into position, a piece of mild-steel plate, 3 ins. by 2 ins, by

in. thick, bent to the correct curvature. To this plate was riveted a piece of Ferodo .?,1 in. thick.

The brake thus made was fitted to the withdrawal shaft midway between the withdrawal arms.