Bonallack Dual-purpose Body for Spillers

Page 111

If you've noticed an error in this article please click here to report it so we can fix it.

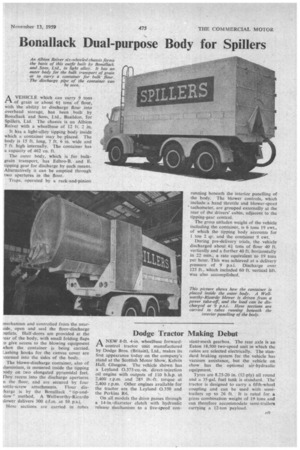

AA VEHICLE which can carry 9 tons of grain or about 6+ tons of flour, with the ability to discharge flour into overhead storage, has been built by Bonallack and Sons, Ltd., Basildon, for Spillers, Ltd. The chassis is an Albion Reiver with a wheelbase of 12 ft. 2 in.

It has a light-alloy tipping body inside which a container may be placed. The body is 15 ft. long, 7 ft. 6 in. wide and 7 ft. high internally. The container has a capacity of 462 Cu. ft.

The outer body, which is for bulkgrain transport, has Edbro-B. and E. tipping gear for discharge by such means. Alternatively it can be emptied through two apertures in the floor.

Traps, operated by a rack-and-pinion mechanism and controlled from the neartide, open and seal the floor-discharge Pullets. Half-doors are provided at the rear of the body, with small folding flaps :o give access to the blowing equipment when the container is being carried. Lashing hooks for the canvas cover are recessed into the sides of the body.

The blown-discharge container, also of durninium, is mounted inside the tipping pody on two elongated pyramidal feet. Fhey recess into the discharge apertures n the floor, and are secured by four mttle-screw attachments. Flour dis:harge is by the Bonallack " tip-and" method. A Wellworthy-Ricardo dower delivers 300 clan. at 10 p.s.i. Hose sections are carried in tubes running beneath the interior panelling of the body. The blower controls, which include a hand throttle and blower-speed tachometer, are grouped externally at the rear of the drivers' cabin, adjacent to the tipping-gear control.

• The gross unladen weight of the vehicle including the container, is 6 tons 19 cwt., of which the tipping body accounts for 1 ton 2 qr. and the container 9 cwt.

During, pre-delivery trials, the vehicle discharged about 61 tons of flour 40 ft. vertically and a further 40 ft. horizontally in 22 min., a rate equivalent to 19 tons per hour. This was achieved at a delivery pressure of 9 p.s.i. Discharge over 125 ft., which included 60 ft. vertical lift, was also accomplished.