THIMBLE TUBE BOILERS: A USER'S EXPERIENCE.

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

The Excellent Results Secured by the Conversion of the Original Water Tube Boilers of a Portion of a Fleet of Steam Wagons.

By C. le M. GOSSELIN (Managing-Director H. Viney and Co., Ltd.).

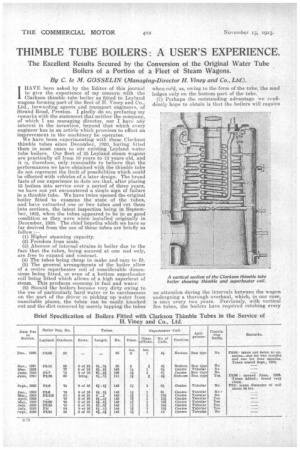

IHAVE been asked • by the Editor of this journal to give the experience of my concern with the Clarkson thimble tube boiler as fitted to Leyland wagons forming part of the fleet of H. Viney and Co., Ltd., forwarding agents and transport engineers, of Strand Road, Preston. I gladly do so, prefacing my renaarks with the statement that neither the company, of which I am managing director, nor I have any interest in the invention, beyond that which every engineer has in an article which promises to effect an improvement in the machinery he operates. We have been experimenting with these Clarkson thimble tubes since December, 1920, having fitted them in most cases to our existing Leyland watee tube boilers. 0111._ fleet of 25 Leyland steam wagons are practically all from 10 years to 13 years old, and it is, therefore, only reasonable to believe that the performances we have obtained with the thimble tube do not represent the limit of possibilities which could be effected with vehicles of a later design. The broad facts of our experience to date are that, after placing 13 boilere into service over a period of three years, we have not yet encountered a single sign of failure in a thimble tube. We have twice opened the original boiler fitted to examine thestate of the tubes, and have extracted one or two tubes and cut them into sections, the latest inspection being in September, 1922, when the tubes appeared to be in as good condition as they were when installed originally in December, 1920. The chief benefits which we have so far derived from the use of these tubes are briefly as follow :— _

(1) Higher steaming capacity.

(2) Freedom from scale.

(3). Absence of internal strains in boiler due to the fact that the tubes, being secured at one end only,

are free to expand and contract. . .

(4) The tubes being cheap to make and easy to fit. (5) The general arrangeMents of the boiler allow of a centre superheater coil of considerable dimennions being fitted, or even of a bottom superheater coil being fitted which allows of a high superheat of steam. This produces economy in fuel and water. (6) Should the boilers become very dirty owing to the use of particularly hard water or to carelessness on the part of the driver in picking up water from unsuitable places, the tubes can be easily knocked out and the dirt removed by merely tapping the tubes

when col-d, as, owing to the form of the tube, the mud lodges only on the bottom part of the tube.

(7) Perhaps the outstanding advantage we con-fidCntly hope to obtain is that the boilers will require no attention dUring the intervals between the wagon undergoing a thorough overhaul, which, in our case, is once every two years. Previously, with vertical fire tubes, the boilers have required retubing every

nine months to 12 months, and, in the case of water tubes, from 12 months to 15 months. If our boilers' will now last for two years, we shall have effected. an enormous saving in the amount of work which devolves on our fitting staff, apart from the cost thereof. The average consumption we obtain is about 1 cwt. of gas coke of average quality per 8i miles. For a wagon and trailer, with a carrying capacity of ten tons, this works out at slightly under 2d. per mile. It is no uncommon experience: to reach so high a; figure as ten miles to 1 cwt.-of coke. which reduces the cost per mile to slightly over lljd. Considering the age of the vehicles and the fact that previously we were unable to obtain more than seven miles to a,bag of coke, we feel the Clarkson thimble tube has affected an enormous improvement in the efficiency of Our wagons. There is no doubt that we are still in the experimental stage in using these tubes, and look forward to obtaining even better results.

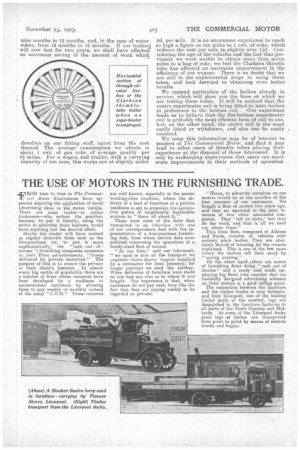

We append particulars of the boilers already, in service, which will show you the lines on which we are testing these tubes. It will be noticed that the centre superheater coil is being fitted to later boilers

in preference to' the bottom coil. Our experience leads us to believe that the flat-bottom superheater coil is probably the most efficient form of coil to use, bqt; on the other hand, the centre coil is the most easily fitted or withdrawn, and also can be easily repaired.

We trust this information. may be of interest to readers of The Commercial Motor, and that it may lead to other users of thimble tubes placing their experience at the disposal of these interested. It is only by exchanging experiences that.users can ficenierarte improvements in their methods of operation