STEAM WAGON BOILER

Page 24

Page 25

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

JBLES : THEIR REMEDIES.

THE TYPES of steam boilers at present in use on motor wagons are all of substantial construetion, and failure of this particular unit is a very rare occurrence, yet it is probably the most expensive unit in upkeep and to repair. The expression " boiler " is here meant to include all the fittings necessary for its operation.

Boiler troubles can be divided into two main classes—those due to faulty construction and thosedue to improper management on the part of the driver. It is undoubtedly the fact that most troubles are of the latter class, especially on boilers where the fuel and water supplies are entirely regulated by the driver_ The important factors in the management of steam boilers are keeping an even water level and en even state of the fire. It is most probable that 90 per cent. of cases.of tubes 4eaking are due either to the water level getting too low or to the fire being improperly supplied with fuel. If the water gets too low the ends of the tubes will be exposed and burnt, and the fusible plug may melt out putting out the fire and causing sudden contraction of the boiler. With bad firing leaking may be caused by holes forming in the fire, through which cool air rushes, then impinging on the tubes, particularly -if this happens near the tube plate ; or, again, it may be caused by allowing the fire to get too thin and then adding too much fuel, which causes the fire to become dead and black, with a consequent big reduction in firebox temperature and unequal expansion. 'Tube leakage can also be caused by improper use of the steam blower, particularly when raising steam. This blower should only be used as a last resource, especially on loco-type boilers, and, in any case, never used when the steam pressure is less than 50 lb.

The Need for Constant Washing Out.

A very frequent cause of trouble is the boiler becoming too dirty through want of washing out. Apart from a tendency to prime, the fittings are liable to become corroded, and cracks may develop in the firebox plates, round the bottom just above the foundation ring and round the firedoor.

. The frequency with which a boiler is washed out is a matter which is not always given proper von-. sideration., It is impossible to lay down a hard and

fast rule and to say that a 'boiler should be washed out every week, as so much depends upon the quality of water picked up. In some districts it is possible to let a, boile.r go for a month without washing out, and in others it is necessary to wash out every week.. Cases also occur where an owner looks upon boiler washouts as a nuisance, and will not allow the driver a reasonable time in which to do the work. With proper management, and providing no other repairs are required, the operation of washing out can be carried out before starting a day's work, and need only delay the wagon about a couple of hours. The boiler should be refilled and the fire lighted immediately the mud plugs are replaced and before all the other fittings are replaced. Naturally, a boiler is stone cold after washing out, and takes some time to warm up, giving ample time to replace the fittings. It also saves much time if the fire can be started with incandescent feel instead of lighting up with oily waste and wood.

If a boiler has been neglected and the inside has become very dirty, apart from the trouble due to priming and probable damage to the firebox plates, a large amount of fuel will' be wasted. A quick and simple way to clean out the boiler is to boil it out with caustic soda. For this purpose, remove some top fitting, such as the safety-valve cover, and put

into the boiler about 2 lb. of caustic soda. Then light the fire and boil out for about 3 hrs. (or more if the boiler is very dirty), keeping the water level well up in the boiler so that all scaly parts are covered. After the boiler has cooled down wash it out, and if the scale is of a soft nature most of it will be found to have been removed.

In some cases, however, where very hard water has been used, the method mentioned will not loosen the hard scale. Some vertical types of boilers are made so that the firebox can he dropped out, when all the interior surfaces can be thoroughly scaled. With the loco-type boiler part of the tubes and the firebox crown are accessible for scraping from the manhole, but a thorough internal scaling can only be made when a new set of tubes and firebox are being fitted.

To a certain extent the formation of hard scale inside a boiler can be prevented by using a composition in the feed-water ; but most of these compounds act by chemical process, and are each only suitable for one kind of water. The majority of steam wagons however, are continually picking up different kinds of water ; consequently, it is impossible to get a chemical compound which will suit all waters.

There are some compounds thaLdo not act by chemical process, and these are the mbst suitable for steam wagon boilers. Very finely ground flaka graphite is one such compound, and this can be used with safety. The graphite must be of-good quality. that mined in Mexico being the best kind to use. The action of graphite is not chemical' it does not dissolve the scale, nor does it attack the metal ; neither is it affected by any acids in the water nor by the heat generated in the boiler. The particles of graphite simply work into the minute cracks in the scale and gradually penetrate between the scale and the metal. Once the scale is removed it is impossible for new scale to adhere to the metal .ag'ain so long as the graphite treatment is continued. The best way to feed the graphite is to put a certain amount into the boiler after every wash out. The quantity Will depend upon the amount and nature of scale-forming material in the feed-water, but an average figure would be 2 oz, An _ equal amount should be put into the water tank every day; • thig will also improve the working of the pump and injector.

Leakage of Tubes the Chief Trouble.

The most frequent trouble with steam-wagon boilers, particularly those of the fire-tube type—i.e., those where the hot gases .pass through tubes surrounded by water, as, for instance, the loco type—is leakage of the tubes. As previously mentioned, this is in most cases due to bad management.. Leaky tubes should never be neglected, for, all the time leakage is taking place scale is forming between the tubes and the plate. This will prevent the tubes making proper contact with the plate when using the expander, and consequently it will be impossible to make them tight until the scale is removed. Before using an expander on any tube the tube should be thproughly cleaned inside to get an even surface for the rollers of the expander to bear against. Plenty of oil should be used to lubricate the rollers of the tube. Tubes should never be expanded when the boiler is hot, except in emergency cases, and it is advisable always to test-the boiler with the hydraulic pump, for it is quite possible that expanding one tube will upset some of the other tubes round IL If the tubes are leaking very badly and many are affected, the best way to tackle the job is to expand all the tubes. Starting on the outside and working round in a ring. In this manner the preasure is evenly distributed all over the plates. It is also a big mistake to over-expand a tube ; it should be just sufficiently expanded to withstand the necessary pressure (one and a half times the working pressure for hydraulic testing). If a tube is over-expanded, the metal will be strained, and it Will never be kept tight again. When the leakage. occurs in the firebox only, this is due to had stoking. Either cold air is being drawn through holes, in the -fire, or the firedoor is allowed to remain open too long. Seine drivers have a bad habit of opening the firedoor to keep the steam pressure down when the fire is too big. The proper remedy is to stoke aceording to demand for steam. To prevent cold air going straight to the tubes a deflector should be fitted to the firedoor if it opens outwards, and, with a loco-type boiler, an additional deflector can be fitted below the tube-plate.

lithe tubes leak at the smokebox end only, this is due to cold air being drawn in round the smokebox door. The door may be bent, or it may require a new joint ring. Many drivers overlook the necessity for maintaining the air-tightness of the smokebox door.

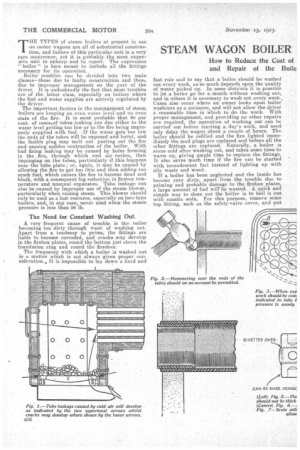

Sometimes, in desperation, a driver will hammer the tubes to make them tight, using the ball end of the hammer, which has the effect of splaying over the tube. Needless to say, such practice should never be allowed, for it completely spoils the tubes, hastening, rather than delaying, the approach of the time when new tubes must be fitted.

When tubes begin to leak incessantly, in spite of careful management, they should all be withdrawn and a new set put in. It is sometimes possible to use some of the old tubes again by cleaning them and trimming the ends, but they should first be very carefully inspected to see if they are pitted. In most cases, when the tubes are withdrawn, it is advisable to put in an entire new set ; it will be much cheaper in the long run. Retubing should always be done by a competent boiler-maker. It is not a job for the Ordinary driver or even for anexperienced fitter. With a fire-tube boiler' if a few tubes have become very thin and it is desired to carry on until a new set is required, ferrules -may be fitted to the defective tubes. Plain ferrules made from solid-drawn steel tube will give best results. They should be slightly tapered on the outside, the small end just small enough to enter the tube about 4 in., and the inner end rounded to facilitate sweeping out. They should be made as thin as Toesible, not more than 3-32 in. alit*, and should protrude out of the tube aboutin. when driven well home. Because of the small size of the tubes in steam-wagon boilers, ferrules should only be used as a stop-gap remedy, for ferruled tubes are difficult to keep clean ; it is impossible to push a tube brush of the proper size straight through the tubes.

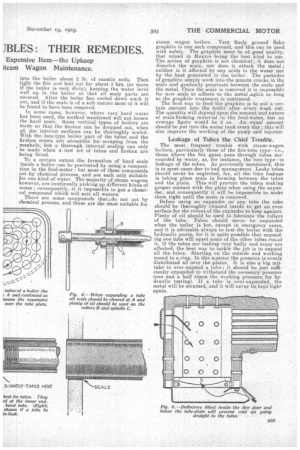

A burst tube is a very rare occurrence, but in such cases the fire should be immediately withdrawn and the boiler allowed to cool down. If it is necessary to carry on for a _pima time until a new tube ca-n be fitted, the defective tube can be blanked off as shown in Fig. 6. The rod should be made about 2 ins. longer than the tube, and screwed right and left-hand at the ends. The two blanks should be made a taper fit in the tube, as previously described for a ferrule, and screwed to fit the rod. The projecting ends of the blanks may be made hexagon to fit a spanner or drilled for a tommybar. When both blanks are well home the ends of the rod should be cutoff and riveted over to nrevent steam leaking along the screw. A new tube should be fitted as soon as possible, and if the tubes are old it is advisable to withdraw them all and fit a new set.

Fusible plugs are fitted to all steam wagon boilers to prevent serious damage should the water get too low. This fitting, however, is often the source of a great B31 deal. of trouble, on account of leakage, even though the water level never gets too low. In American locomotive practice fusible plugs are never used for this reason ; but it would not be safe to omit them on steam-wagon boilers, where. the water level fluctuates so quickly. When a plug burns out because the water is too low it is entirely the fault of the driver, providing the i

water gauge s in proper working order. Invariably, when this happens, the tubes will leak, especially with the .loco.-type boiler. A driver who permits this to happen should be seriously warned.

Sometimes, however, a plug will burn out even though the water has never got too low. This is caused by the plug becoming covered with scale inside the boiler and consequently the fusible metal melts out. The obvious remedy for this is to remove the plug for inspection periodically, say every three months.

Trouble is often experienced by leakage past the thread of the plug, especially after it has been removed a few times. This is due to the thread becoming worn in the boiler plate, or :to the plug being cross-threaded when being screwed in. It very often occurs that a plug cannot be screwed out, but has to be chipped out, when the thread is liable to be damaged. In such cases it is a simple matter to tap out the boiler plate to a slightly larger size and fit an oversize plug to suit. Fusible plugs are sup plied by the makers in sizes 1-3,2 in., in., and 4 in. above standard size, and taps to correspond are obtainable.

Sometimes; however, due to leakage and corrosion, the boiler-.plate becomes thin round the plug-hole. To remedy this the old hole should be plugged with a solid mild steel taper plug, and a new hole drilled and tapped in the boiler plate for a standard size plug, choosing a suitable place where the plate is in good condition.

When a boiler has been in use for a few years, and particularly if it has been carelessly used, cracks may appear in the firebox plates. These usually appear round the bottom of the firebox, where the scale and mud are liable to -lodge, which causes overheating. When the firebox is square, as in most loco-type boilers the cracks usually begin at the corners, due to the ;harp bend which weakens the material, and to scale and mud accumulatiag here unless mudholes are provided at each corner.

[In the continuation of this article, to appear in next week's issue, the author (" Hephiestus ') will deal with these cracks in fireboxes, plate bulging, defects of stays, firedoor joints, mudhole doors, gauges, check valves, injectors, etc.—ED., The C